6

- 3

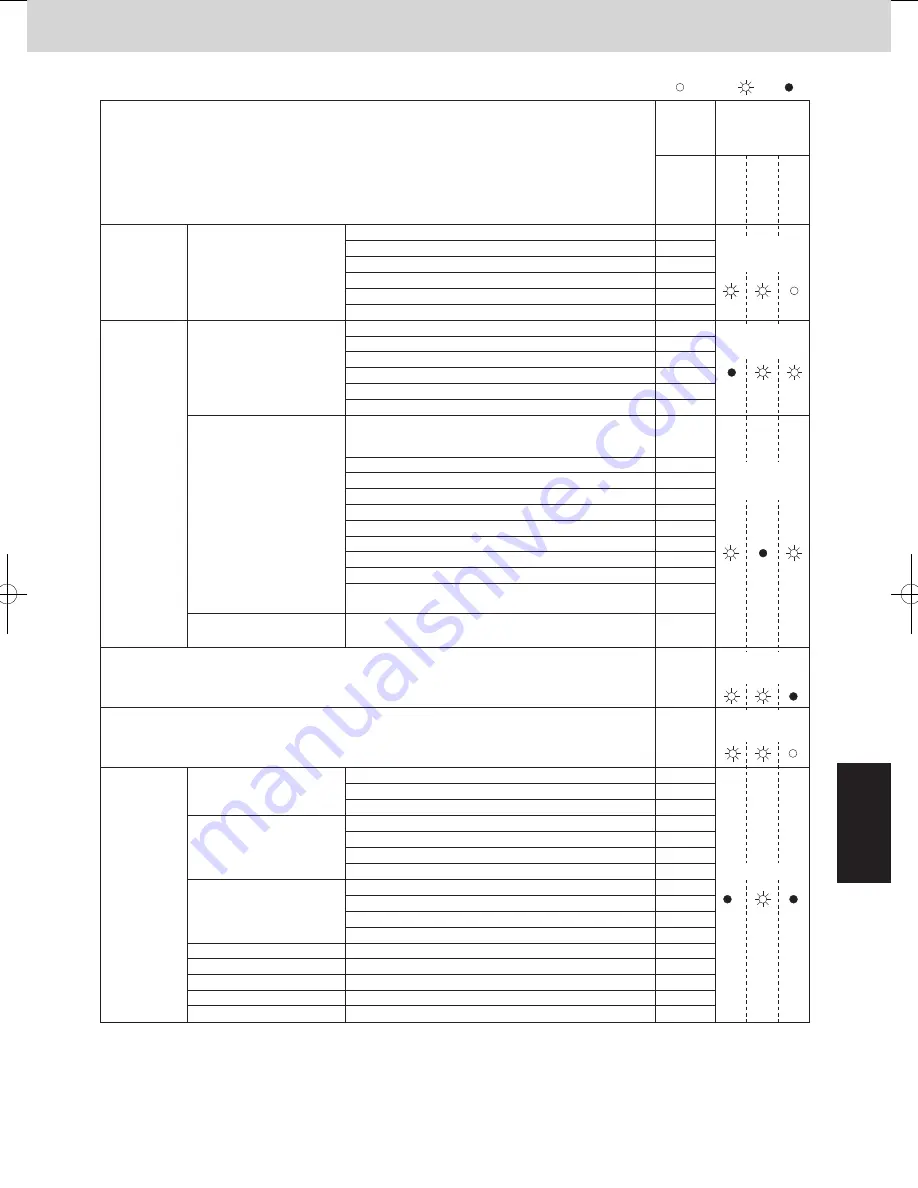

1. Contents of Remote Controller

Switch Alarm Display

2WAY SYSTEM

Trouble Diagnosis

6

1.Contents of Remote Controller

Switch Alarm Display

2WAY SYSTEM

Trouble Diagnosis

ON: Blinking:

OFF:

Possible cause of malfunction

Wired

remote

control

display

Wireless

remote controller

receiver display

Operatio

n

Timer

Standby

for heatin

g

Serial

communication

errors

Mis-setting

Remote controller is detecting

error signal from indoor unit.

Error in receiving serial communication signal. (Signal from

main indoor unit in case of group control) Outdoor system

address, indoor unit address, or indoor unit address

independent/main/sub unit setting has not been made.

(Auto address is not completed.)

Error in transmitting serial communication signal.

Indoor unit is detecting error signal from remote controller and system controller.

Indoor unit is detecting error

signal from outdoor unit.

Error in receiving serial communication signal.

When turning on the power supply, the number of

connected indoor units does not correspond to the number

set. (Except R.C. address is “0.”)

Group wiring failure of indoor units in the refrigerant system

(occurring when remote controller is operated immediately

after automatic address setting)

•

•

•

<E01>

<E02>

<<E03>>

<<E09>>

<<L09>>

F05

F06

F07

F08

E04

E08

<E06>

Outdoor unit is detecting error

signal from indoor unit.

Error in receiving serial communication signal.

There is an indoor unit which does not send signals when

the power is ON.

•

•

Indoor unit address setting is duplicated.

•

Duplicated remote controller “main” setting.

•

Automatic address setting start is prohibited.

AP pin was short-circuited at time when automatic address

setting was started.

Indoor unit communication

error of group control wiring.

Error of main indoor unit in receiving serial communication

signal from sub indoor units.

During auto. address setting,

number of connected units

does not correspond to

number set.

Improper setting

Improper setting

Improper setting

Indoor unit

Number of connected indoor units is less than the number set.

Number of connected indoor units is more than the number set.

No indoor unit is connected during auto. address setting.

Main outdoor unit is detecting error signal from sub outdoor unit.

Duplicated outdoor unit address.

Improper wiring between main outdoor unit and sub-unit.

Error of sub outdoor unit in receiving serial communication

signal from main outdoor unit.

Outdoor unit serial communications failure.

Communication error between the microcomputers

Connected indoor unit is not a multi unit.

Duplication of main indoor unit address setting in group control.

Duplicated indoor unit priority (priority indoor unit).

Duplicated indoor unit priority (non-priority indoor unit) and

outdoor unit.

Indoor unit address is not set.

Capacity code of indoor unit is not set.

Mismatch of outdoor unit type.

4-way valve operation failure

Duplication of outdoor R.C. address setting.

Capacity code of outdoor unit is not set.

Group control wiring is connected to individual control indoor unit.

E12

E18

E16

E20

E15

E24

E25

E27

E29

E30

E31

<L03>

L06

L08

L05

<<L02>>

L04

L17

L18

L10

L07

Thermistor fault

Comp. No. 2 discharge gas temp. sensor (DISCH2)

Outdoor No. 1 coil gas temp. sensor (EXG1)

Outdoor air temp. sensor (TO)

Outdoor No. 1 coil liquid temp. sensor (EXL1)

Continued

Operating lamp

blinking

Heating ready lamp

blinking

Operating lamp

blinking

Heating ready lamp

blinking

Operating and heating

ready lamps blinking

simultaneously

Operating and heating

ready lamps blinking

simultaneously

F04

Comp. No. 1 discharge gas temp. sensor (DISCH1)

<<F02>>

<<F03>>

<<F10>>

<<F11>>

Indoor coil temp. sensor (E2)

Indoor coil temp. sensor (E3)

Indoor discharge air temp. sensor (BL)

Indoor suction air (room) temp. sensor (TA)

Operating and

timer lamps blinking

alternately

<<F01>>

Indoor coil temp. sensor (E1)

Mismatch in “No. of outdoor units” setting.

E26

Thermistor fault Outdoor unit

Operating and timer

lamps blinking

altemately

F22

Comp. No. 3 discharge gas temp. sensor (DISCH3)

ON: Blinking:

OFF:

Possible cause of malfunction

Wired

remote

control

display

Wireless

remote controller

receiver display

Operatio

n

Time

r

Standb

y

fo

r heatin

g

Thermistor fault Outdoor thermistor is either

open or damaged.

Compressor intake temp. sensor (SCT)

High pressure sensor failure. High pressure trouble.

Low-pressure sensor failure

Outdoor No. 2 coil liquid temp. sensor (EXL2)

Outdoor No. 2 coil gas temp. sensor (EXG2)

Temp. sensor at refrigerant gas outlet of dual-tube (SCG)

Improper wiring connections of ceiling panel.

Activation of

protective

device

Protective device in indoor

unit is activated.

Thermal protector in indoor unit fan motor is activated.

Float switch is activated.

Operation of protective function of fan inverter.

Protective device in outdoor

unit is activated.

O

2

sensor (detects low oxygen level) activated

F12

F16

F17

F24

F23

F14

<<P09>>

<<P12>>

<<P10>>

Faulty drain pump. Drain pump locked.

<<P11>>

<<P01>>

P14

Compressor thermal protector is activated. Power supply

voltage is unusual. (The voltage is more than 260 V or less

than 160 V between L and N phase.)

Incorrect discharge temperature. (Comp. No. 1)

High pressure switch is activated.

Negative (defective) phase.

DCCT overcurrent

Incorrect discharge temperature. (Comp. No. 2)

Compressor 3 (constant speed) discharge temp. trouble

High load alarm

Outdoor unit fan motor is unusual.

Inverter for compressor is unusual.

(DC compressor does not operate.)

When alarm message in other indoor units occurs in case of

group control, unalarmed state of indoor units are inoperative.

Indoor unit communication

error of group control wiring.

P02

P04

P03

P05

P20

P18

P17

P29

<P31>

P22

P16

Operating and timer

lamps blinking

alternately

Timer and heat

ready lamp blinking

alternately

Operating and heat

ready lamp blinking

alternately

1.Contents of Remote Controller

Switch Alarm Display

2WAY SYSTEM

Trouble Diagnosis

< > alarm indication: In some cases may affect the operation of other indoor units.

Abnormal device function

<< >> alarm indication: Does not affect the operation of other indoor units.

IPM trip (IPM current or temperature)

EEPROM on indoor unit PCB failure

EEPROM on the main or sub outdoor unit PCB has failed.

Protective

device

for compressor

is activated

Protective device for

compressor No. 1 is activated.

Operating and timer

lamp blinking

simultaneously

Operating and timer

lamp blinking

simultaneously

Protective device for

compressor No. 2 is activated. Compressor No. 2 current trouble (locked)

Compressor No. 2 CT sensor disconnected or short circuit

Compressor No. 2 discharge temp. sensor disconnected

Low pressure switch is activated.

Comp. No. 1 oil sensor

Oil sensor fault.

(Disconnection, etc.)

Comp. No. 2 oil sensor

Timer lamp blinking

Current is not detected when comp. No. 1 is ON.

H31

F29

F31

H12

H11

H13

H15

H06

H08

H27

Comp. No. 3 oil sensor

H28

H03

Compressor No. 1 discharge temp. sensor disconnected

H05

H01

Compressor No. 1 current trouble (overcurrent)

Compressor No. 2 current trouble (overcurrent)

Protective device for

compressor No. 3 is activated. Compressor No. 3 current trouble (locked)

Compressor No. 3 CT sensor disconnected or short circuit

Compressor No. 3 discharge temp. sensor disconnected

H22

H21

H23

H25

Compressor No. 3 current trouble (overcurrent)

SM830204-05_2WAY SYS.indb 3

2015/01/20 17:45:16

Summary of Contents for U-20ME1E81

Page 54: ... MEMO 1 46 ...

Page 102: ... MEMO 3 36 ...

Page 116: ... MEMO 4 14 ...

Page 177: ...201502 ...