6

- 19

2WAY SYSTEM

Trouble Diagnosis

6

4. 2WAY Alarm Codes

2WAY SYSTEM

Trouble Diagnosis

4. 2WAY Alarm Codes

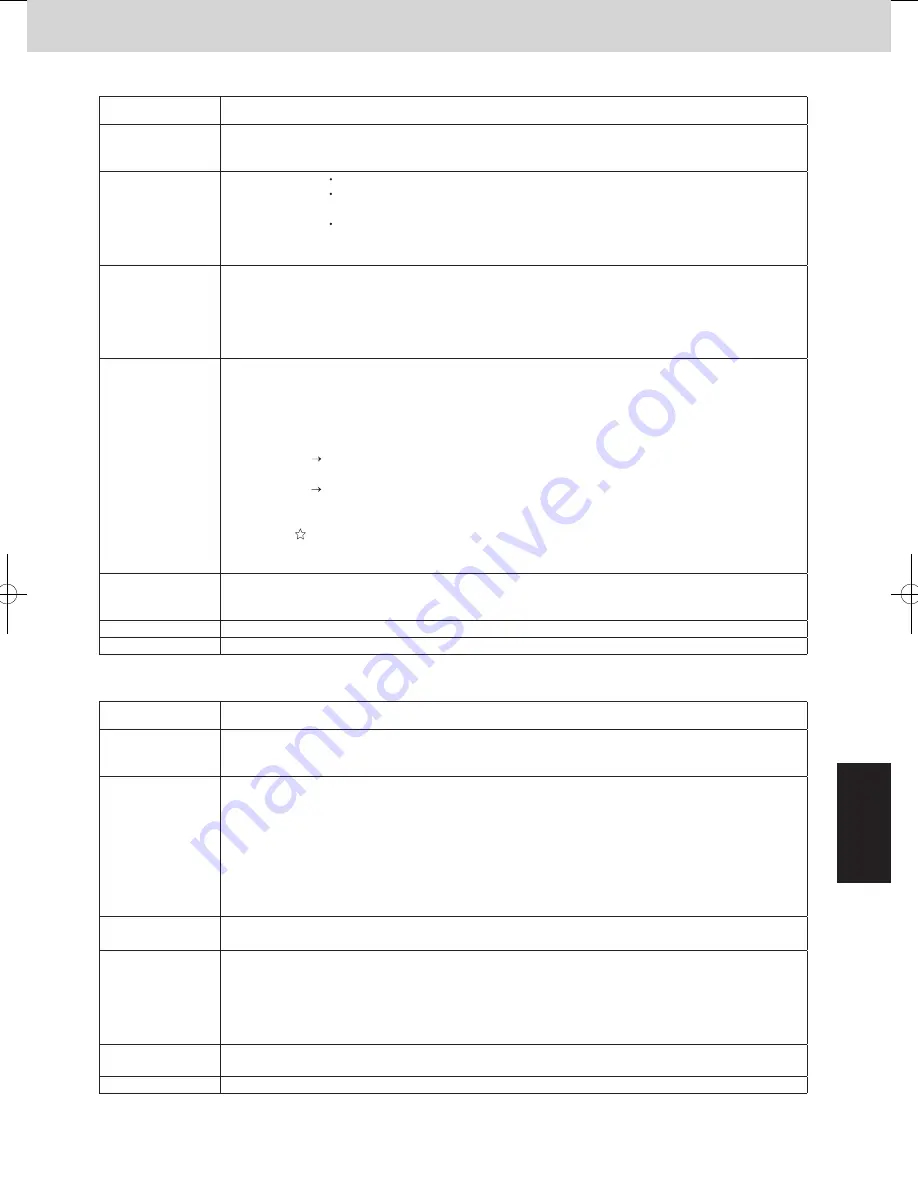

H11, H12, H21, H22 Alarm

Alarm code

H11, H12, H21, H22

Alarm meaning

H11:

H12:

H21:

H22:

Constant speed compressor 2 overcurrent alarm

Constant speed compressor 2 lock current alarm

Constant speed compressor 3 overcurrent alarm

Constant speed compressor 3 lock current alarm

During operation, when the compressor current value exceeds the following values

for 30 seconds or longer listed below table.

However this alarm is not detected for 4 seconds after the compressor starts.

H11, H21:

Alarm conditions

Probable cause

(1) Compressor failure (locked or partially locked)

(2) CT circuit failure (including wiring disconnection)

(3) Missing power phase

(4) Low power voltage

(5) PCB failure

Check

(1) Compressor failure (partially locked)

Trouble: Current value during operation greatly exceeds the value shown above.

Check: When the current for each phase is measured with a clamp meter or similar

instrument, check that the current value for all phases is not high. If MG was forced

ON (use caution), check that compressor noise will not occur or the compressor

will not run with a groaning sound.

(2) CT circuit failure, PCB failure

Trouble:

Check: • Check for poor connector contact.

Check the continuity of the CT circuit.

Install a normal CT in place of this CT and check. If current is detected, then the

PCB can be judged OK.

CT circuit failure

→

→

Check that current is flowing in the phase where the CT circuit is connected.

Check voltage and current.

(3) Missing power phase

Trouble: This alarm primarily occurs when the T-phase is missing. When the R-phase or

S-phase is missing, CT trouble or PCB continuity trouble occur. However this may not

be true in the case of a missing phase caused by magnet SW trouble.

Check: There is the possibility of a magnet SW failure. Therefore, check the phase voltage at

a location that is as close to the compressor as possible.

(4) Low power voltage

Trouble: In most cases, this occurs when another constant-speed compressor (including

compressors in other units) or other device starts. It also occurs when the power

wiring is extremely long.

Check: Check the voltage between each of the phases. However if this trouble occurs when

other devices or compressors start, then an oscilloscope is required.

(5) PCB failure

Trouble:

Check: Check that the current value measured with the clamp meter is not lower than the

value measured with the PC or remote controller.

If the cause is still unknown after checking the above, then it is possible that noise is the

(6)

cause of the trouble. It is necessary to connect a PC or other instrument.

•

•

•

Correction

(1) Replace the compressor.

(2) Replace the CT circuit.

(3) Repair the power circuit.

(4) Adjust the primary-side power. Repair the power wiring.

(5) Replace the outdoor unit PCB.

(6) Correct the trouble.

* In the case of a compressor failure, it is likely that steps must be taken to correct the cause

of the compressor failure (such as liquid back-up) in order to prevent recurrence. Be sure to

check that there is no cause which may result in compressor locking.

Example

—

Horsepower of outdoor unit

Overcurrent (A)

12HP

16.3

14HP

13.6

16HP

16.3

18HP

13.6

20HP

16.3

During operation, when the compressor current value exceeds the following values

for 4 seconds or longer listed below table.

However this alarm is not detected for 2 seconds after the compressor starts.

H12, H22:

Horsepower of outdoor unit

Overcurrent (A)

12HP

19.3

14HP

16.1

16HP

19.3

18HP

16.1

20HP

19.3

H03, H13, H23 Alarm

2WAY SYSTEM

Trouble Diagnosis

4. 2WAY Alarm Codes

H05, H15, H25 Alarm

Alarm code

H05, H15, H25

Alarm meaning

H05 : Compressor 1 discharge temperature sensor disconnected

H25 : Compressor 3 discharge temperature sensor disconnected

Alarm conditions

This alarm occurs when the discharge sensor temperature detector is not inserted into the tube’s

sensor holder, or when the sensor itself has suffered some kind of malfunction other than a cut

wire.

When outdoor air temperature is -10°C or higher:

Alarm occurs if the temperature detected by the discharge sensor has changed by less than

2°C when the compressor has operated for 10 minutes immediately after start.

When outdoor air temperature is below -10°C:

Alarm occurs if the temperature detected by the discharge sensor has changed by less than

2°C when the compressor has operated for 30 minutes immediately after start.

•

•

•

Probable cause

(2) Discharge sensor itself has suffered some kind of malfunction other than a cut wire.

Check

(1) Discharge sensor temperature detector is not inserted into the tube’s sensor holder.

(1) Check that the discharge temperature sensor is inserted into the sensor holder.

(2) Check that sufficient heat-conducting putty is applied.

(3) Remove the discharge sensor from the sensor holder and expose the sensor to the outside

air for approximately 5 minutes. Check that the temperature detected by the sensor changes

to match the outside air temperature. (However the sensor cannot detect temperatures at or

below 0 °C.)

Correction

(1) Install the sensor into the holder, and apply sufficient heat-conducting putty.

(2) If the sensor is malfunctioning, replace it.

Example

H15 : Compressor 2 discharge temperature sensor disconnected

Alarm code

H03, H13, H23

Alarm meaning

H03 : Compressor 1 CT sensor disconnected or short-circuit

H23 : Compressor 3 CT sensor disconnected or short-circuit

Alarm conditions

Compressor 1:

Compressor 2, 3:

When the compressor 1(INV) is stopped, the primary current detected over 18A.

Current values at compressor 2 and 3 are less than 2.0 A when 2 seconds or more

had passed after the compressors began operation and output.

When the frequency of compressor 1(INV) is over 35Hz and the secondary current

is over 7.0A, the primary current detected lower than 0.7A.

* No current is detected even though the compressors are operating.

Probable cause

(2) Disconnected CT circuit connector

(3) Missing phase where CT circuit is connected

(4) This CT circuit is connected to the connector of the other CT circuit.

(5) PCB failure

(6) Electrical noise

Check

(1) CT circuit failure (including cut wiring, etc.)

(1) CT circuit failure, PCB failure

Trouble:

• Current v

alue during compressor operation is below the threshold value.

Check:

• Che

ck that the connector is not disconnected.

Check the continuity of the CT circuit.

Install a normal CT in place of this CT and check. If current is detected, then the

PCB can be judged OK.

CT circuit failure

Check that current is flowing in the phase where the CT circuit is connected.

Check voltage and current.

(2) Crossed wiring or installation error

Trouble: When the compressor is stopped, the current value at the other compressor is high.

When this type of condition occurs, seizing-detection control takes priority.

(3) If the cause is still unknown after checking the above, then it is possible that noise is the

cause of the trouble. It is necessary to connect a PC or other instrument.

•

•

•

Correction

(1) Replace the CT circuit.

(2) Replace the outdoor unit PCB.

(3) Correct the problem.

Example

(1) The connector was not inserted after the PCB was replaced.

Notes

Use a normal CT as a tool to determine whether the trouble is a PCB failure or CT failure.

H13 : Compressor 2 CT sensor disconnected or short-circuit

SM830204-05_2WAY SYS.indb 19

2015/01/20 17:45:20

Summary of Contents for U-20ME1E81

Page 54: ... MEMO 1 46 ...

Page 102: ... MEMO 3 36 ...

Page 116: ... MEMO 4 14 ...

Page 177: ...201502 ...