2WAY SYSTEM

Control Functions

-

Outdoor Unit

1

- 14

1

4. Output of PCB

4-7. Refrigerant interception valve [O2*]

*O2 valve is the local supply parts.

This valve works when the outdoor unit receives signal of the refrigerant leakage from the indoor unit.

The indoor unit that transmits the signal of the refrigerant leakage gives “P14”alarm.

To activate this function, it is necessary to set it to EEPROM on the main outdoor PCB and indoor PCB.

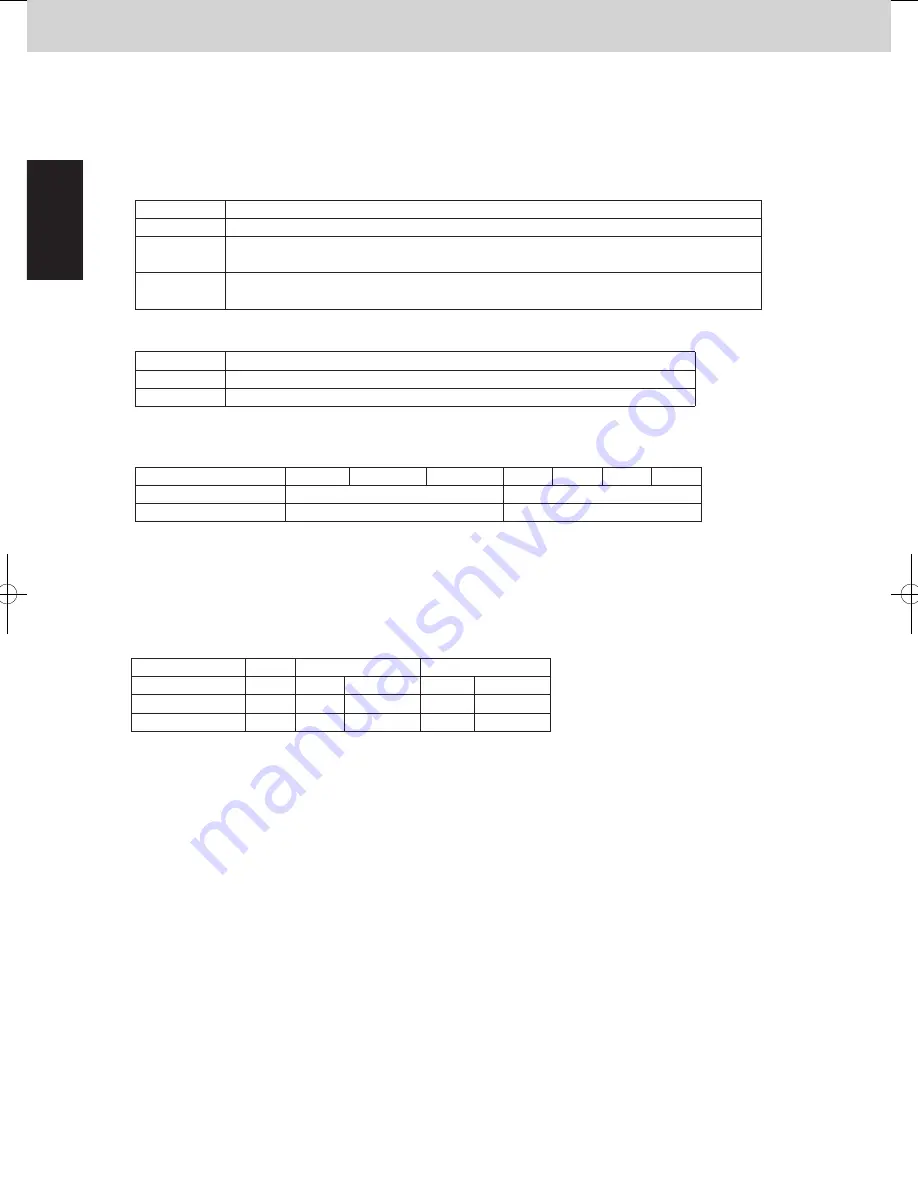

EEPROM setting in main outdoor unit

CODE: C1

Setting No.

Setting No.

0

0

1

1

2

This function invalid (factory preset mode)

This valve is turned OFF when the system is normal.

This valve is turned ON when the outdoor unit receives signal from the indoor unit.

This valve is turned ON when the system is normal.

This valve is turned OFF when the outdoor unit receives signal from the indoor unit.

EEPROM setting in indoor unit

CODE: 0B

Function of EXCT plug short-circuit

Indoor unit does thermostat OFF

(factory preset mode)

Indoor unit gives “P14”alarm and transmits the refrigerant leakage signal.

4-8. MOV for heat exchanger [MOV1, MOV2]

4-8-1. Type of Motor Operated Valves

Outdoor unit Capacity

8HP

10HP

12HP

14HP 16HP 18HP 20HP

MOV1

For heat exchanger in upper row For left side heat exchanger

MOV2

For heat exchanger in lower row For right side heat exchanger

4-8-2. Power Initialization

If no indoor units have started (even once) after the power supply to the outdoor unit, the MOV for heat

exchanger holds the pulse at 480 pulses.

4-8-3. Operation of MOV for heat exchanger

MOV operates according to the mode of indoor unit.

Mode of system Stop

Cooling

Heating

Compressor

Stop

Stop Operation

Stop

Operation

MOV 2 (pulse)

0

0

480

0

0 - 480

MOV 1 (pulse)

0

0

480

0

0 - 480

*If any one compressor in the outdoor unit is operating at heating mode, both MOVs perform SH control of heat

exchanger.

SH control adjusts the difference between the liquid temperature and gas temperature to -1 - 5 degree.

3WAY SYSTEM

Control Functions

4. Output of PCB

4-9. SC Circuit Electronic Control Valve [MOV4]

4-9-1. SC Control (Cooling Mode only)

During cooling operation, the liquid refrigerant which condenses at the outdoor unit heat exchanger flows into

the receiver tank, and SC (sub-cool = supercooling) approaches 0°C. When SC is small and the length of the

tubing connecting the indoor and outdoor units is long, the refrigerant flow in the indoor unit will be reduced sig-

nificantly. To prevent this trouble from occurring, MOV4 operates so as to increase supercooling in the double

tube coil near the outlet of the outdoor unit.

In addition, MOV4 controls refrigerant flow volume so that it will not flow back to the compressor in the liquid

state. SH in suction that is difference between the SCG temperature and low pressure sensor temperature is

adjusted to 3-5°C.

4-9-2. Discharge temperature control of compressor

When the discharge temperature increases to 95°C or more, MOV 4 opens to 100 pulses to cool down the

compressor. MOV 4 operates according to the state of the discharge temperature between 20 - 480 pulses. This

operation takes priority over SC control.

This operation is continued until discharge temperature decreases to 80°C or less.

4-10. Crankcase Heater Control [CH1, CH2

, CH3

]

When the compressor stops, the crankcase heater of its own compressor is turned ON.

Liquid

(SC=0deg)

Liquid

(Large SC)

MOV4

(SH control)

Gas returns to

accumulator

Refrigerant on the inner side evaporates,

cooling the liquid refrigerant on the outer side.

SCG

(Discharge temperature control of compressor.)

Liquid returns to

accumulator

Does not fully evaporate,

resulting in liquid back-up.

Liquid

Liquid

MOV4

SCG

SM830204-05_2WAY SYS.indb 14

2015/01/21 17:00:00

Summary of Contents for U-20ME1E81

Page 54: ... MEMO 1 46 ...

Page 102: ... MEMO 3 36 ...

Page 116: ... MEMO 4 14 ...

Page 177: ...201502 ...