34

Unit side

insulator

Insulation tape (white)

(supplied)

Sealer (supplied)

Flare insulator (supplied)

Tube insulator

(not supplied)

Heat resistant

248°F or above

Vinyl clamps (supplied)

Flare nut

Fig. 5-8

Fig. 5-7

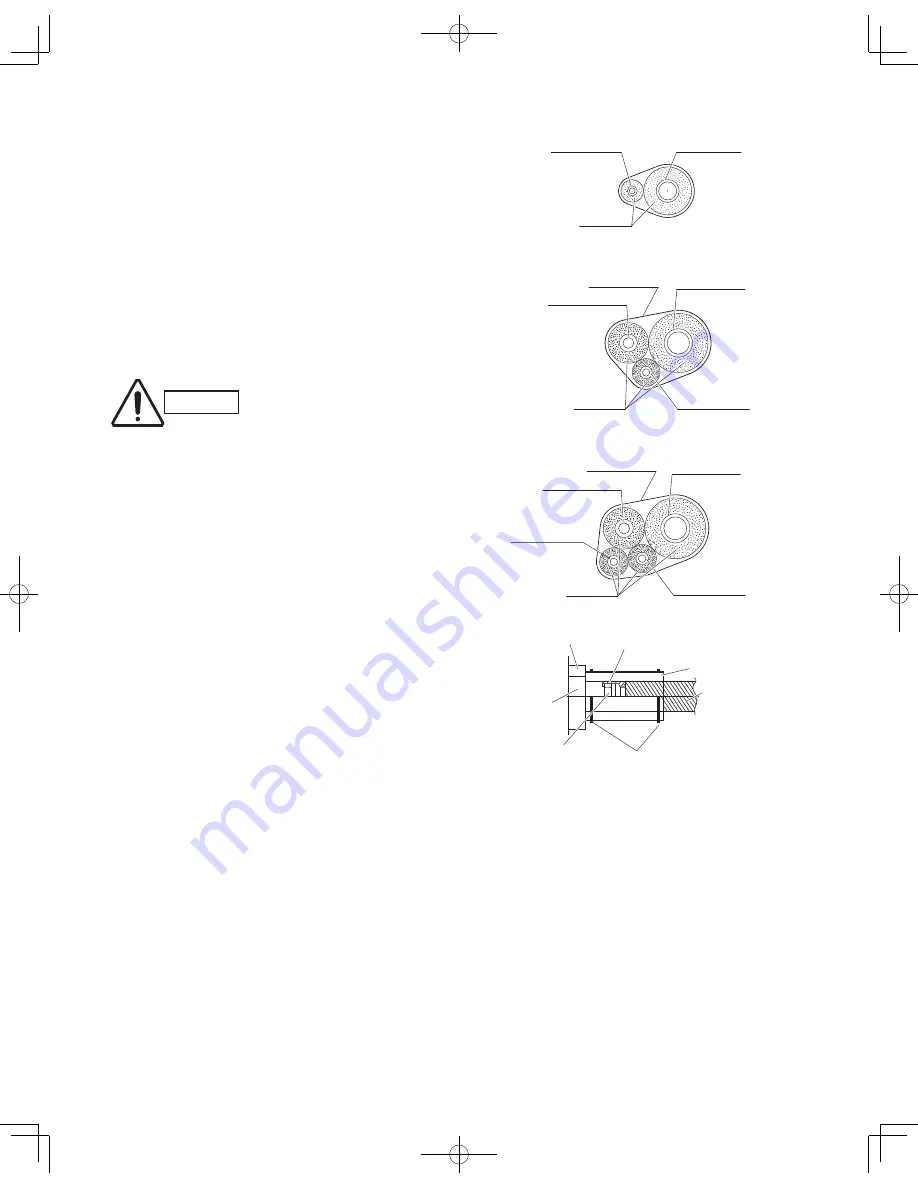

5-3. Insulating the Refrigerant Tubing

Tubing Insulation

●

Thermal insulation must be applied to all unit tubing,

including the distribution joint (purchased separately).

(Fig. 5-7)

* For gas tubing, the insulation material must be heat

resistant to 248°F or above. For other tubing, it

must be heat resistant to 176°F or above.

Insulation material thickness must be 25/64 in. or

greater.

If the conditions inside the ceiling exceed DB 86°F

and RH 70%, increase the thickness of the gas

tubing insulation material by 1 step.

Taping the flare nuts

Wind the white insulation tape around the flare nuts at

the gas tube connections. Then cover up the tubing

connections with the flare insulator, and fill the gap

at the union with the supplied black insulation tape.

Finally, fasten the insulator at both ends with the

supplied vinyl clamps. (Fig. 5-8)

CAUTION

Gas tubing

Liquid tubing

Insulation

Three tubes arranged together

Two tubes arranged together

If the exterior of the outdoor unit

valves has been finished with

a square duct covering, make

sure you allow sufficient space

to use the valves and to allow

the panels to be attached and

removed.

Cosmetic

(finishing) tape

Liquid tubing

Gas tubing

Insulation

Balance tubing

Suction tubing

Cosmetic

(finishing) tape

Discharge tubing

Liquid tubing

Balance tubing

Insulation

Four tubes arranged together

W-3WAY̲ECO-i̲U.indb 34

W-3WAY̲ECO-i̲U.indb 34

2011/11/07 16:29:37

2011/11/07 16:29:37

Summary of Contents for U-72MF1U9

Page 53: ...53 W 3WAY ECO i U indb 53 W 3WAY ECO i U indb 53 2011 11 07 16 29 45 2011 11 07 16 29 45...

Page 54: ...54 W 3WAY ECO i U indb 54 W 3WAY ECO i U indb 54 2011 11 07 16 29 45 2011 11 07 16 29 45...

Page 55: ...55 W 3WAY ECO i U indb 55 W 3WAY ECO i U indb 55 2011 11 07 16 29 45 2011 11 07 16 29 45...