4

1.3.

Standard for Repair Service

Repair service shall be provided in accordance with repair technology information such as service manual

so as to prevent fires, injury or electric shock, which can be caused by improper repair work.

1. When performing repairs, neither the products nor its parts or components shall be modified.

2. If cable assembly is supplied as the smallest unit when servicing, make sure to replace

the cable assembly.

1.4.

For Service Technicians

ICs and LSIs are vulnerable to static electricity.

When repairing, the following precautions will help to prevent recurring malfunctions.

1. Cover the plastic parts with aluminum foil.

2. Ground the soldering irons.

3. Use a conductive mat on the worktable.

4. Do not grasp IC or LSI pins with bare fingers.

1.5.

About Lead Free Solder (PbF: Pb free)

Note

•

In the information below, Pb, the symbol for lead in the periodic table of elements, will refer to standard solder or solder

that contains lead.

•

We will use PbF when discussing the lead free solder used in our manufacturing process which is made from Tin (Sn),

Silver (Ag), and Copper (Cu).

•

This model, and others like it, manufactured using lead free solder will have PbF stamped on the PCB. For service and

repair work we suggest using the same type of solder.

Distinction of PbF PCB

•

PCBs (manufactured) using lead free solder will have a PbF stamp on the PCB.

Caution

•

PbF solder has a melting point that is 50

°

- 70

°

F, (30

°

- 40

°

C) higher than Pb solder.

Please use a soldering iron with temperature control and adjust it to 700

°

± 20

°

F (370

°

± 10

°

C).

• Exercise care while using higher temperature soldering irons.: Do not heat the PCB for too long time in order to

prevent solder splash or damage to the PCB.

•

PbF solder will tend to splash if it is heated much higher than its melting point, approximately 1100

°

F (600

°

C).

•

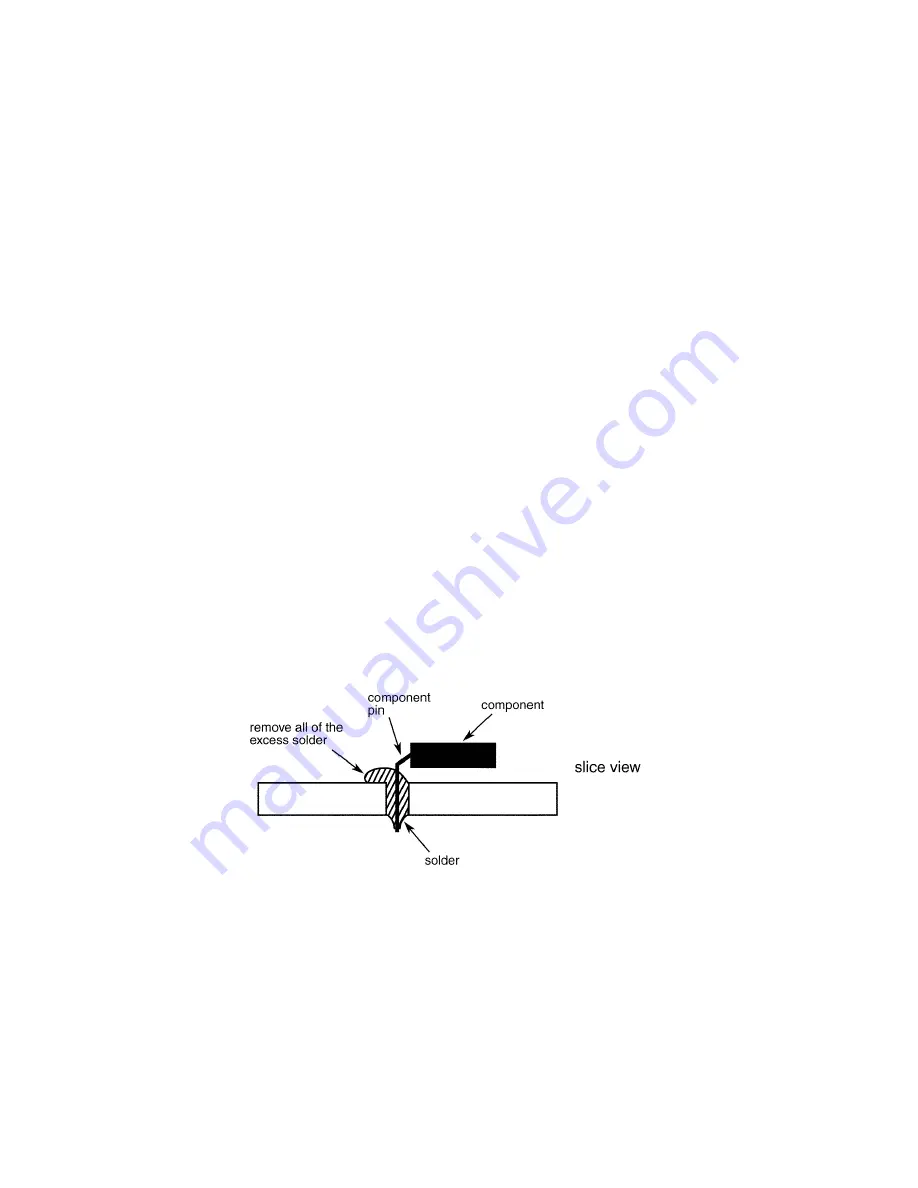

When applying PbF solder to double layered boards, please check the component side for excess solder which may

flow onto the opposite side (See figure below)

1.5.1.

Suggested Pb free solder

We recommend you to use the following solder when re-soldering components for repair. Before using other Pb free solder than the

following solder, make sure to confirm that the solder maker (you use) has the license agreement for Pb free solder.

Supplier: Senju Metal Industry Co., Ltd. (http://www.senju-m.co.jp)

Part Description in Senju: EcoSolder RMA02 P3 M705 Series

Summary of Contents for UB-5338C

Page 9: ...9 2 3 External View ...

Page 10: ...10 2 4 Control Panel Operation ...

Page 11: ...11 2 5 External Dimensions 2 5 1 UB 5838C ...

Page 12: ...12 2 5 2 UB 5338C ...

Page 101: ...101 13 Exploded View and Replacement Parts List ...

Page 102: ...102 13 1 Framework of Projected Diagram ...

Page 103: ...103 13 2 Cabinet Unit ...

Page 105: ...105 13 3 Motor Drive Unit Sensor Unit ...

Page 107: ...107 13 4 Control Box Unit ...

Page 109: ...109 13 5 Screen Feed Roller Unit ...

Page 111: ...111 13 6 Scanner Unit ...

Page 113: ...113 13 7 Panel Unit ...

Page 115: ...115 13 8 Frame Unit ...

Page 117: ...117 13 9 Rear Cover Unit ...

Page 119: ...119 13 10 Packing ...