38

9 TROUBLESHOOTING

9.1.

LED Status

Note: *

Disassembling the unit will be required to remove the USB cable from the unit and/or reassemble it.

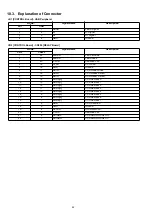

Symptom

Possible Cause

Check Point

1. The Status LED does

not light up.

The connection between elite Panaboard

and PC is not proper.

*

1. Check the connection between the elite Panaboard and

PC.

2. Plug the USB cable to another USB interface on the PC

The USB cable from the elite Panaboard

is connected to PC via a USB Hub.

1. Plug the USB Cable to the PC, directly.

The USB cable has a failure.

*

1. Replace the USB cable.

The connection between CONTROL

Board and LED Board is not proper.

1. Check the connection between CN4 and CN200

LED Board has a failure.

1. Check the following signal on the LED Board.

(1) CN200-3rd pin: + 5 V (Approx.)?

=> If yes, replace the LED Board.

CONTROL Board has a failure.

1. Replace the elite Panaboard.

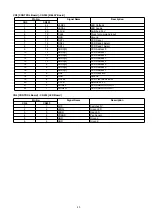

2. The Status LED turns

red.

USB cable was plugged in while touching

the screen surface on the elite

Panaboard.

1. Unplug the USB cable.

Then, after 5 seconds or more, plug the USB cable again

without touching the screen surface

The reflection tape attached inside the

screen frame becomes dirty.

1. Clean the reflection tape around the screen frame

2. Replace the tape with a new one.

3. Restart the elite Panaboard.

Then check that the LED turns green.

The reflection tape is peeled from the

inside of the screen frame.

1. Replace the tape with a new one.

2. Restart the elite Panaboard.

Then check that the LED turns green.

Magnets or similar objects have been

attached to the Screen Board.

Remove the magnets or other similar objects from the

Screen Board.

An object has been placed on the Lower

Frame.

Get rid of the object.

The connection between CONTROL

Board and Sensor (CMOS Camera

Module) is not proper.

1. Check the following connections.

(1) Between CN2 and CN300

(2) Between CN301 and Sensor (CMOS Camera Module

(Right))

(3) Between CN3 and CN300

(4) Between CN301 and Sensor (CMOS Camera Module

(Left))

2. Replace faulty cables.

RELAY Board (Right and/or Left) has a

failure.

1. Replace faulty boards.

The optical axis of the Sensor is straying

from its ideal path.

1. Replace the elite Panaboard.

Sensor (CMOS Camera Module) does not

work properly.

1. Replace the elite Panaboard.

Summary of Contents for UB-T580

Page 11: ...11 3 COMPONENT IDENTIFICATION 3 1 Main Unit ...

Page 12: ...12 3 2 Stylus Pen ...

Page 17: ...17 4 5 Unpacking the elite Panaboard from Its Packaging ...

Page 28: ...28 5 SECTIONAL VIEW ...

Page 48: ...48 12 CIRCUIT BOARDS Index 12 1 RELAY Board 12 2 LED Board ...

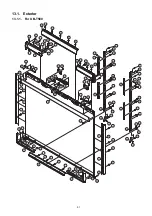

Page 50: ...50 13 PARTS LOCATION AND MECHANICAL PARTS LIST ...

Page 53: ...53 13 1 2 For UB T580W To be continued later ...

Page 56: ...56 13 2 2 For UB T580W To be continued later ...

Page 57: ...57 14 REPLACEMENT PARTS LIST ...