26

8.2.

Adjustment

8.2.1.

White balance adjustment

Name of measuring instrument

Connection

Remarks

• W/B pattern

• Color analyzer

(Minolta CA-100 or equivalent)

Component input

Panel surface

Procedure

Remarks

• Make sure the front panel to be used on the final set is fitted.

• Make sure a color signal is not being shown before adjustment.

• Put the color analyzer where there is little color variation.

1. Output a white balance pattern.

2. Check that the color temperature is [Cool].

3. Set to serviceman mode, WB-ADJ.

4. Set [R-CUT] [G-CUT] [B-CUT] the values written in table 1.

5. Attach the sensor of color analyzer to the center of highlight window.

6. Fix G drive at C0h and adjust [B-DRV] and [R-DRV] so x, y value of color analyzer

become the [Color temperature High] in table 2.

7. Increase RGB together so the maximum drive value in RGB becomes FC. That is,

set [ALL DRIVE] to FC.

Execute adjustment again. When that, the maximum value of R/G/B DRV should be FC,

and either R/G/B DRV should be FC.

8. Set color temperature to [Normal].

9. Set [R-CUT] [G-CUT] [B-CUT] the values written in table 1.

10. Attach the sensor of color analyzer to the center of highlight window.

11. Fix G drive at C0h and adjust [B-DRV] and [R-DRV] so x, y value of color analyzer

become the [Color temperature Mid] in table 2.

12. Increase RGB together so the maximum drive value in RGB becomes FC. That is,

set [ALL DRIVE] to FC.

Execute adjustment again. When that, the maximum value of R/G/B DRV should be FC,

and either R/G/B DRV should be FC.

13. Set color temperature to [Warm].

14. Set [R-CUT] [G-CUT] [B-CUT] the values written in table 1.

15. Attach the sensor of color analyzer to the center of highlight window.

16. Fix G drive at C0h and adjust [B-DRV] and [R-DRV] so x, y value of color analyzer

become the [Color temperature Low] in table 2.

17. Increase RGB together so the maximum drive value in RGB becomes FC. That is,

set [ALL DRIVE] to FC.

Execute adjustment again. When that, the maximum value of R/G/B DRV should be FC,

and either R/G/B DRV should be FC.

18. Set color temperature to [Cool].

- adjustment of [Normal] [Warm] by data shift from [Cool] adjust. -

For [Normal] [Warm] adjustment, set values that the adjusted value of [Cool]

plus the figures wrote below.

When the measurement data is not in the following tolerance by the shipping confirma-

tion, please re-adjust.

Tolerance : ( x , y ) = ( setting data±0.007, setting data±0.007)

19. Copy values adjusted by HD pattern to the NTSC data area of EEPROM.

Summary of Contents for Viera TH-50PE8U

Page 15: ...15 6 4 No Picture ...

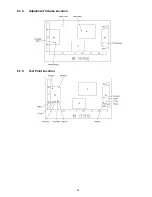

Page 25: ...25 8 1 4 Adjustment Volume Location 8 1 5 Test Point Location ...

Page 27: ...27 ...

Page 28: ...28 ...

Page 34: ...34 ...

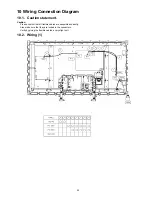

Page 36: ...36 10 3 Wiring 2 ...

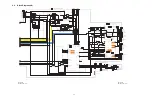

Page 37: ...37 11 Schematic Diagram 11 1 Schematic Diagram Note ...

Page 94: ...94 13 1 2 Accessories ...

Page 95: ...95 13 1 3 Mechanical Replacement Parts List ...

Page 98: ...98 13 2 Electrical Replacement Parts List 13 2 1 Replacement Parts List Notes ...