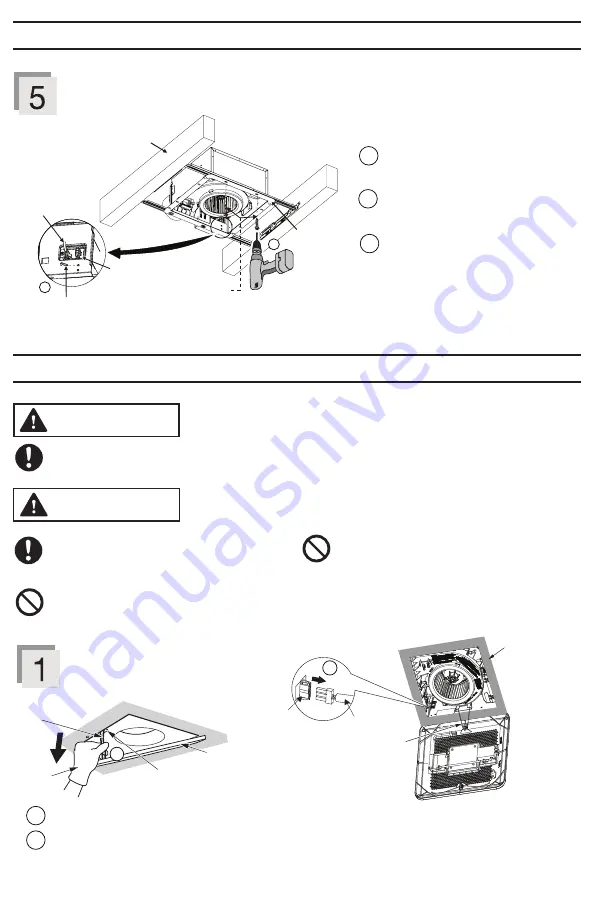

Secure fan body

Flange

Joist

1

2

Plug connector

Receptacle

Machine screw (M4X8)

2 self-drilling screws

WARNING

CAUTION

Disconnect power supply before working on unit.

Routine maintenance must be done every

year. Please wear gloves during the

cleaning work.

Do not immerse motor in water when

cleaning. Do not soak resin parts in

water over 140° C (60

° F

).

Never use gasoline, benzene, thinner or

any other such chemicals for cleaning the

ventilating fan.

Remove grille

1

2

1

Gloves

Slot

Grille

Mounting spring

Remove grille by pulling down one mounting spring.

Disconnect the wire from the receptacle, then pull down the other mountain spring.

1

2

Plug connector into receptacle and secure

fan body to adaptor by using the machine

screw (M4X8).

When the flange overlaps Flex-Z Fast™

bracket, secure it by using 2 self-drilling

screws.

Follow the steps 7 to 8 in INSTALLATION

(RETROFIT)

3

Mounting spring

LED lamp wire

Receptacle

2

Drywall

10

MAINTENANCE (CLEANING)

INSTALLATION (NEW CONSTRUCTION) (CONTINUED)