– 40 –

– 41 –

4. Chip Capacitor

The capacitive value of replacement chip capacitors is

indicated on the bottom surface. original parts do not have

value indication.

If the capacitive value is less than 100 pF, the value will be

indicated by one or two digit number expressing the capacity

directly in pF.

Example:

0.5

0.5 pF 2.5

2.5 pF

.75

0.75 pF 33

33 pF

1

1 pF 82

82 pF

If the capacitive value is 100 pF or greater, the value will be

indicated by an alpha-numeric code. The letter precedes the

number and expresses a numerical value to be multiplied by

the number which follows.

Numerical Value

* Letters I and O are not used.

Example: A1

10 x 10

Q

= 100 pF

N2

33 x 10

W

= 3300 pF

S3

47 x 10

E

= 47000 pF

5. Precautions in replacing the chip component

1. Make sure that the unit is turned OFF when replacing the

chip.

2. Use tweezers to prevent any damage to the chip surface.

3. Do not re-use the chips after removal.

4. Do not rub the electrode of chips.

5. Do not subject the chips to excessive stress.

6. It is recommended that a pencil-type soldering iron to be

used.

7. The solder whose diameter is less than 0.5 mm is

recommended.

8. Do not heat the chip beyond 3 second.

9. Maintain temperature control under 260°C (500°F) when

soldering.

Multiplier (1 - 5)

Numerical Value

Letter

Value

A 10

B 11

C 12

D 13

E 15

F 16

G

18

H

20

J

22

K

24

L

27

M

30

Letter

Value

N 33

P

36

Q

39

R 43

S

47

T

51

U

56

V

62

W

68

X

75

Y

82

Z

91

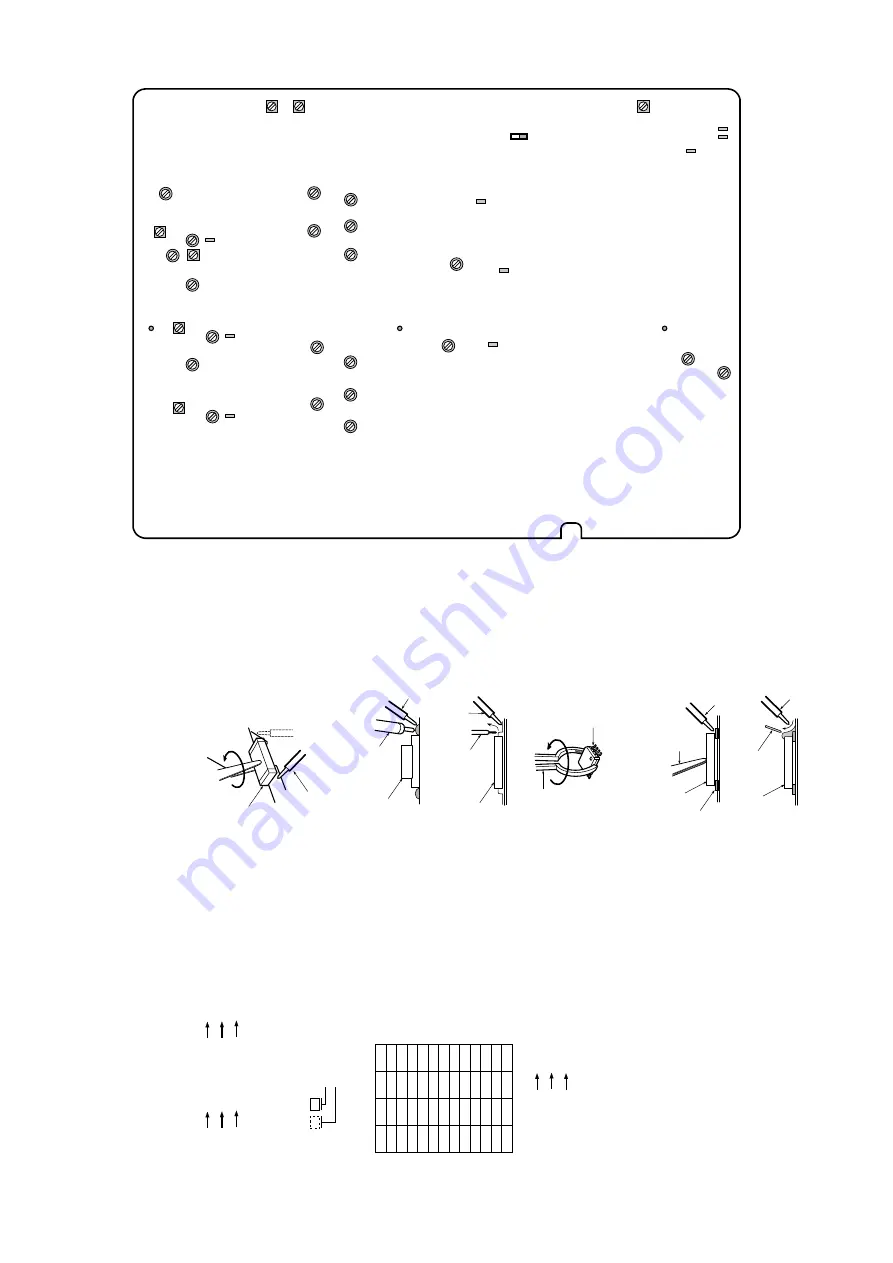

5-1.

Removal (Transistor, Diode, Resistor and

Capacitor)

1. Add the solder to both ends of the chip (three leads for

chip transistor).

2. While attaching the soldering iron to both ends of the chip

(three leads for chip transistor) as shown below, remove

the chip by turning with tweezers.

Note:

Be careful not to damage other chips.

5-2.

Removal (IC)

1. Add the solder wick and soldering iron to each lead of the

IC and remove solder.

2. Add the soldering iron to each lead of the IC and left each

lead of the IC using thinner pin.

3. Remove IC

turning it with pliers.

5-3. Mounting

1. Place the solder thinly on the chip mounting foil.

2.

Solder the chip temporarily while holding the chip with the

tweezers.

3.

Solder both ends of chip (three leads for chip transistor).

Tweezers

Chip

Soldering iron

Chip

Solder wick

Soldering iron

Chip

Thinner Pin

Soldering iron

Pliers

Turn

Chip

Chip

Tweezers

Soldering iron

Solder

Solder

Soldering iron

Chip

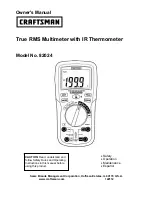

LOCA

TION OF TEST POINTS AND ADJUSTING CONTROLS

VR102 (RA C-PHASE)

TP101 (RA SC)

CT901

(CHARA POSITION)

CT902

(CHARA DIVIDER)

CT101

(RA SC)

VR101 (RA C-GAIN)

VR201

(RB C-GAIN)

CT201

(RB SC)

TP1 (GND)

VR202

(RB C-PHASE)

TP201

(RB SC)

CT903

(4fsc)

TP902

(+5V)

TP903

(–5V)

TP901

(4fsc)

SW901

(PICTURE STABILITY)

OFF

ON

TP801 (RA HD)

TP802 (RB HD)

TP803 (RC HD)

VR802 (RC HD)

TP2 (GND)

TP3 (GND)

VR804 (Y DIVIDER)

VR803 (BURST GAIN)

VR410

(B-Y C-PED (L))

VR409 (B-Y C-GAIN (L))

VR408 (R-Y C-PED (L))

VR406 (Y-GAIN (L))

VR407 (Y-PED (L))

VR404 (B-Y C-GAIN (U))

VR401 (Y-GAIN (U))

VR402 (Y-PED (U))

VR403 (R-Y C-PED (U))

VR405

(B-Y C-PED (U))

VR301

(RC C-GAIN)

CT301

(RC SC)

VR302

(RC C-PHASE)

TP301

(RC SC)

MAIN BOARD (COMPONENT SIDE)

(REAR SIDE)

(FRONT SIDE)

VR801 (RB HD)

VR103

(RA PHASE 2)

T101

(RA PHASE 1)