9

For the case of the camera with M6 screws being used:

Use the screws supplied with the bracket and a hexagonal

wrench "for M6".

(Recommended tightening torque (for common use in M5

and M6): 2.45 N·m {1.81 lbf·ft})

Step 4

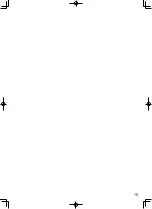

Seal the slit of the cable cap for the prevention of water

leakage.

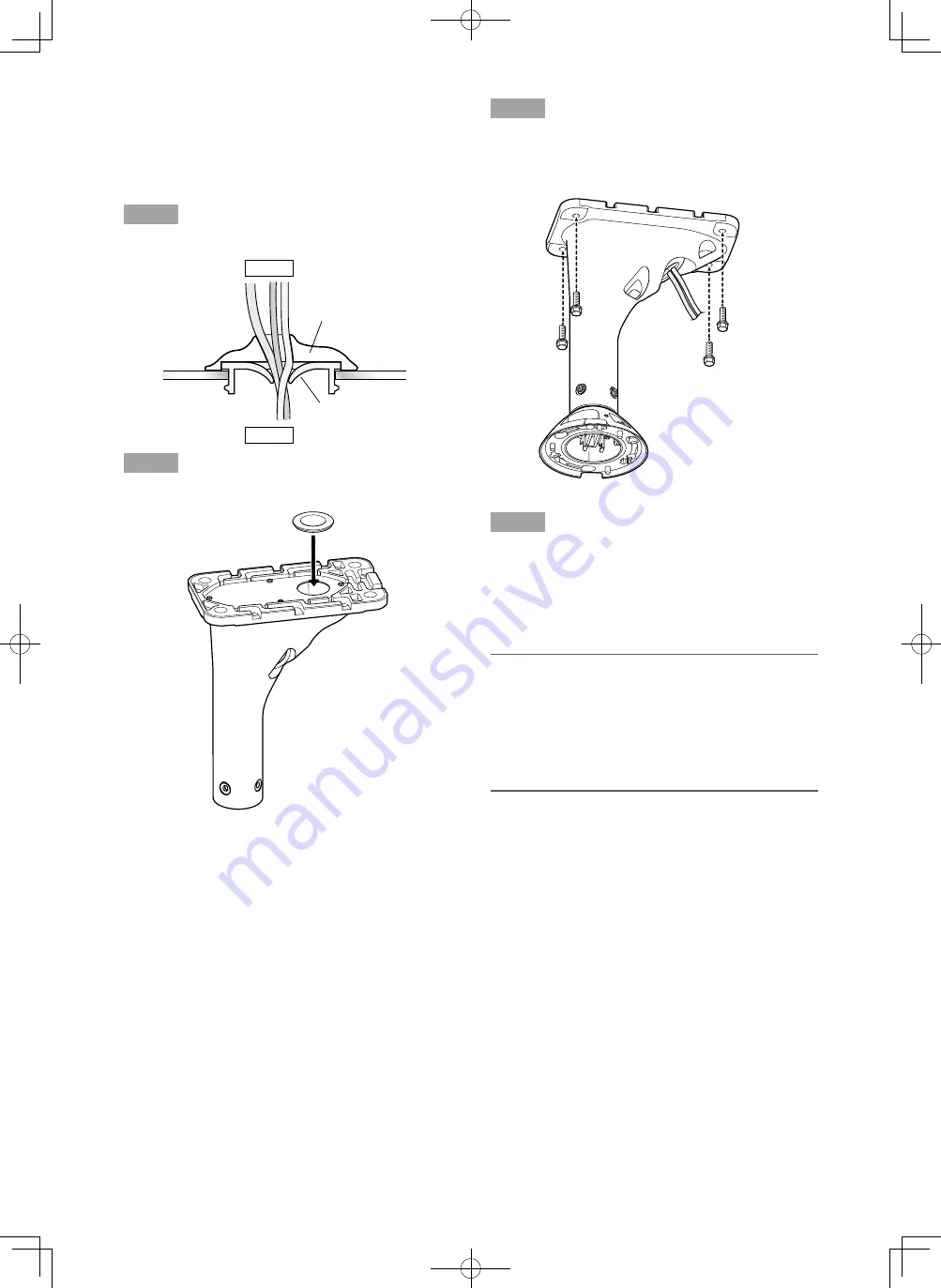

Step 5

Mount another cable cap (accessory) on the rear plate.

* The housing base is not shown in the illustration above.

Outside

Inside

Cable

Sealant (locally procured)

Cable cap (with a slit)

Step 6

Mount the ceiling

mount bracket on the ceiling with

4 screws (M10: locally procured).

Minimum pull-out strength: 1411 N {317 lbf}/per 1 pc.

Step 7

Connect the cables to the camera outside the cable access

hole (front) of the WV-Q121B.

Connect the cables from the housing base with the cables

on the ceiling.

After cable connection, seal the connecting portion with

waterproof tape (locally procured).

IMPORTANT:

• These operations shall be performed in accordance

with the electric installation engineering standards.

Perform sealing to prevent the connecting portion of the

cables from being exposed.

Moisture may come into the camera from the gap

among the cables and cause the inside of the dome

cover to become foggy.

Go to "[3] Mounting of the camera body on the mount

bracket" (

☞

12 page).

Summary of Contents for WV-Q121BS

Page 15: ...15 ...