15/05/96

37

MPC2000 01/96B

The t6x setting must now be calculated. This is set as the time taken to trip at 6 x FLC for the Cold Starting condition

and is set in conjunctio n with the Hot/Cold Ratio setting.

For the above typical motor the Hot Withstand time is 11 seconds, the Cold Withstand is 22 seconds, therefore the

Hot/Cold ratio is calculated as 11/22 x 100 = 50%.

As a general rule the relay should be set to trip at no closer than 80% of the Thermal withstand Time, which in this

case is 80% x 22 sec = 17.6 secs. Therefore set t6x = 17 secs and set Hot/Cold Ratio = 50%

From the standard MPC2000 Thermal Operating Curves the Cold curve trip times can be calculated by mu ltiplying the

setting t6x and the factor 't' for various multiples of FLC i.e.:

Multiple of FLC

1.5

2.0

3.0

4.0

5.0

6.0

Trip time (secs)

366

175

71

39

24

17

From the Hot Curve for Hot/Cold Ratio =50% trip times can be calculated as follows:

Multiple of FLC

1.5

2.0

3.0

4.0

5.0

6.0

Trip Time (secs)

230

102

40

22

14

9.5

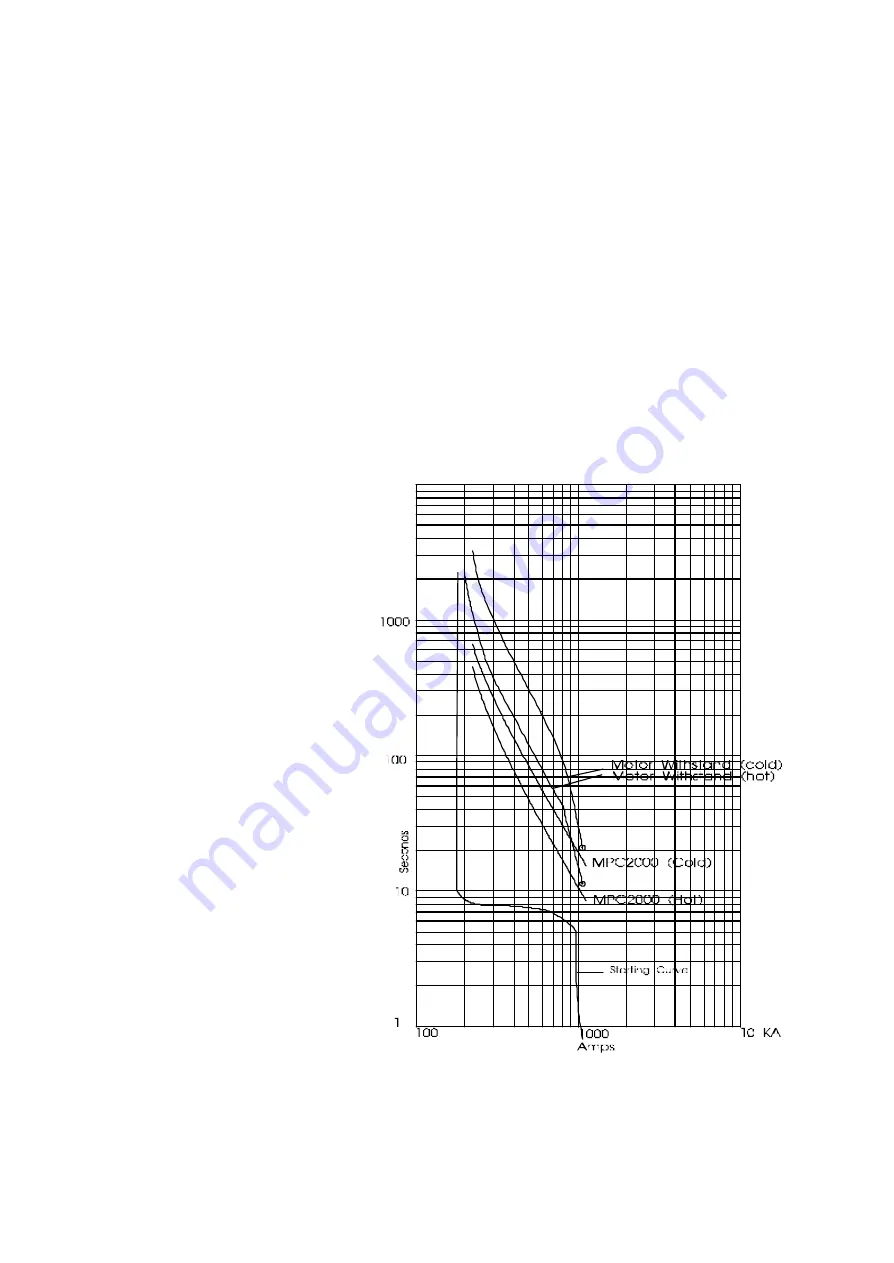

The curves shown on the right are the

actual curves for the calculated figures and

show that the setting has been chosen to

provide close protection to take advantage

of the motors capability and allow the

possibility of an immediate restart from the

Hot condition. However alternative

settings can be made to provide faster

tripping limited by the conditions of

ensuring the motor can run up speed

under healthy conditions without tripping.

If the Hot to Cold ratio is set to a figure

other than the 3 standard curves drawn,

then either the formula quoted below can

be used or an approximation of the Hot

curve can be drawn to calculate trip times.

(Starting/Cold Condition)

tc = 32.a.loge

( p2 )

--------

p2 - s2

where 'p' is multiple of motor FLC (per unit

value)

's' is overload setting in per unit

value e.g. 105%

'a' is setting of t6x in seconds

'tc is the operating time in

seconds