For Technical Support: www.panduit.com/resources/install_maintain.asp

INSTALLATION INSTRUCTIONS PN256D

3.2.1

PLUG

JACK

3.2.2

3. FERRULE TERMINATION

3.1 TERMINATION PREPARATION

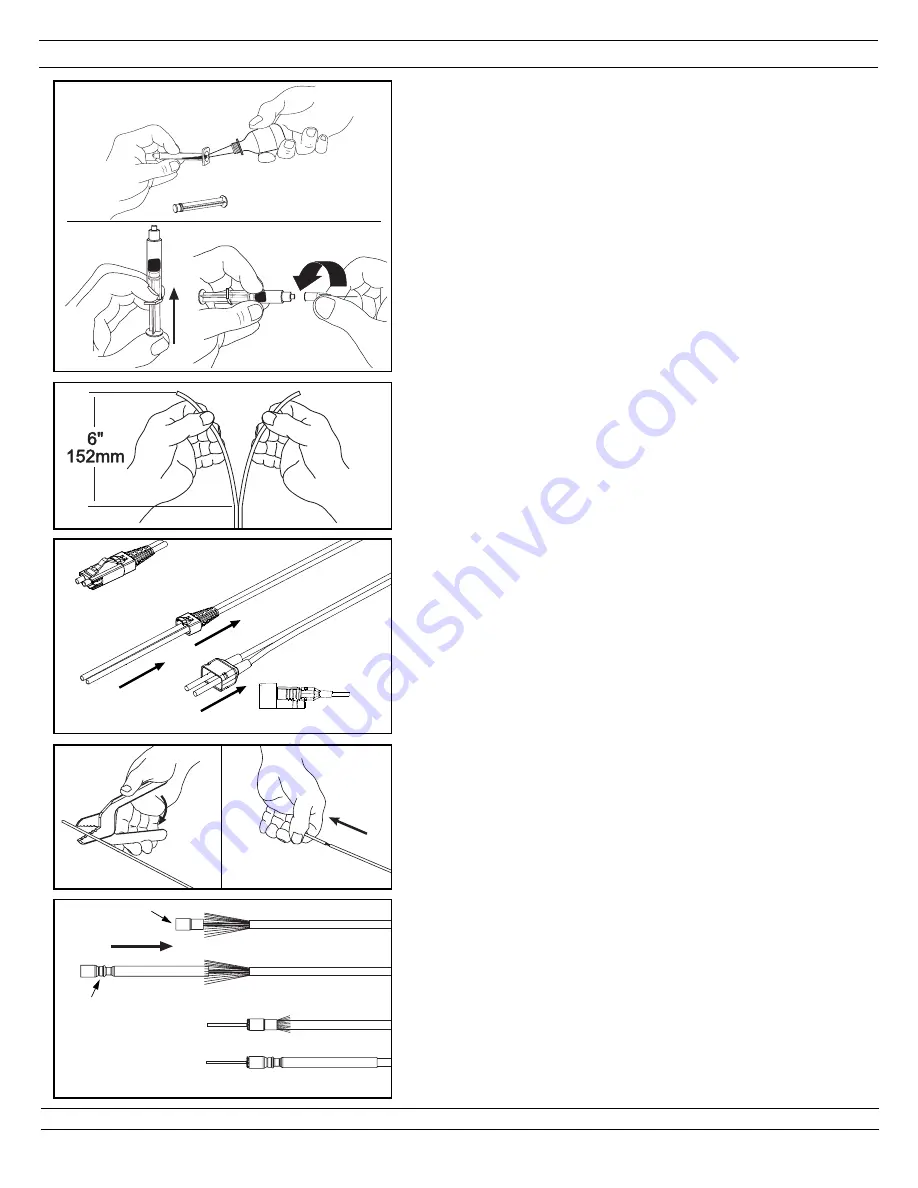

3.1.1 Remove the plunger from a syringe. Squeeze about 0.5 ml

of FJPXY Anaerobic Adhesive into the back of the syringe

barrel. Insert the plunger. Point opening upward, and

squeeze any air out of the barrel. Attach needle to syringe.

Adhesive that is stored in a syringe may start to harden

within 24 hours.

3.1.2 Partially fill a second syringe with about 0.5ml of FJPMR

Primer. Do this by drawing primer up into the syringe barrel

rather than pouring it in through the back.

3.2 3.0mm/2.0mm/1.6mm JACKET / 900µm BUFFER

STRIPPING

Refer to Page 1 or appropriate

PANDUIT

laminated tem-

plate

for stripping dimensions.

3.2.1

For jacketed duplex cable:

Split the two cables

approximately 6" (152mm) or as needed depending on

desired jacket stripping length.

3.2.2 Insert the fiber end through the small end of the appropriate

boot for your specific fiber type. Slide the boot back out of

the way.

Note: For plug termination only, maintain proper

orientation of the fibers by using the ‘A’ and ‘B’ marks

on the plug insert and boot to your specific wiring

convention.

3.2.3

For jacketed cable only:

To reduce wear on the jacket

stripper blades, do not slide the blades along the aramid

yarn. Instead, use the tool to cut through the jacket, then

pull off the jacket by hand.

For 3.0mm jacketed fiber

, use

the third hole (marked “1.3MM” or #16AWG) from the tip of

the jacket stripper.

For 2.0mm/1.6mm jacketed fiber

, use

the first hole (marked “.80MM” or #20AWG) from the tip of

the jacket stripper. Using the cable jacket stripper, strip the

required length of the jacket off of each fiber according to

the stripping dimensions.

3.2.4

For jacketed cable only:

Insert each fiber through the

smaller end of the crimp sleeve. Use the crimp sleeve to

fold the aramid yarn back over the jacket, holding it out of

the way.

3.2.5

For jacketed cable only:

Use the marking pen and

stripping dimensions provided to mark each buffer from the

end of the jacket.

3.2.6

For 900µm buffered fiber only:

Using the marking pen,

place a mark 1" (25mm) from the end of the buffer.

3.2.7 With the buffer stripper provided, strip the buffer.

3.1.1

ADHESIVE

Page 3 of 8

3.2.3

3.2.4

3.0mm Crimp

Sleeve

2.0mm/1.6mm

Crimp Sleeve

3.0mm Crimp Sleeve

2.0mm/1.6mm Crimp Sleeve