For Technical Support: www.panduit.com/resources/install_maintain.asp

INSTALLATION INSTRUCTIONS PN256D

3.4

CRIMPING

For jacketed cable only

.

Note: Be careful not to break the bare fibers

protruding from the ferrules during this step.

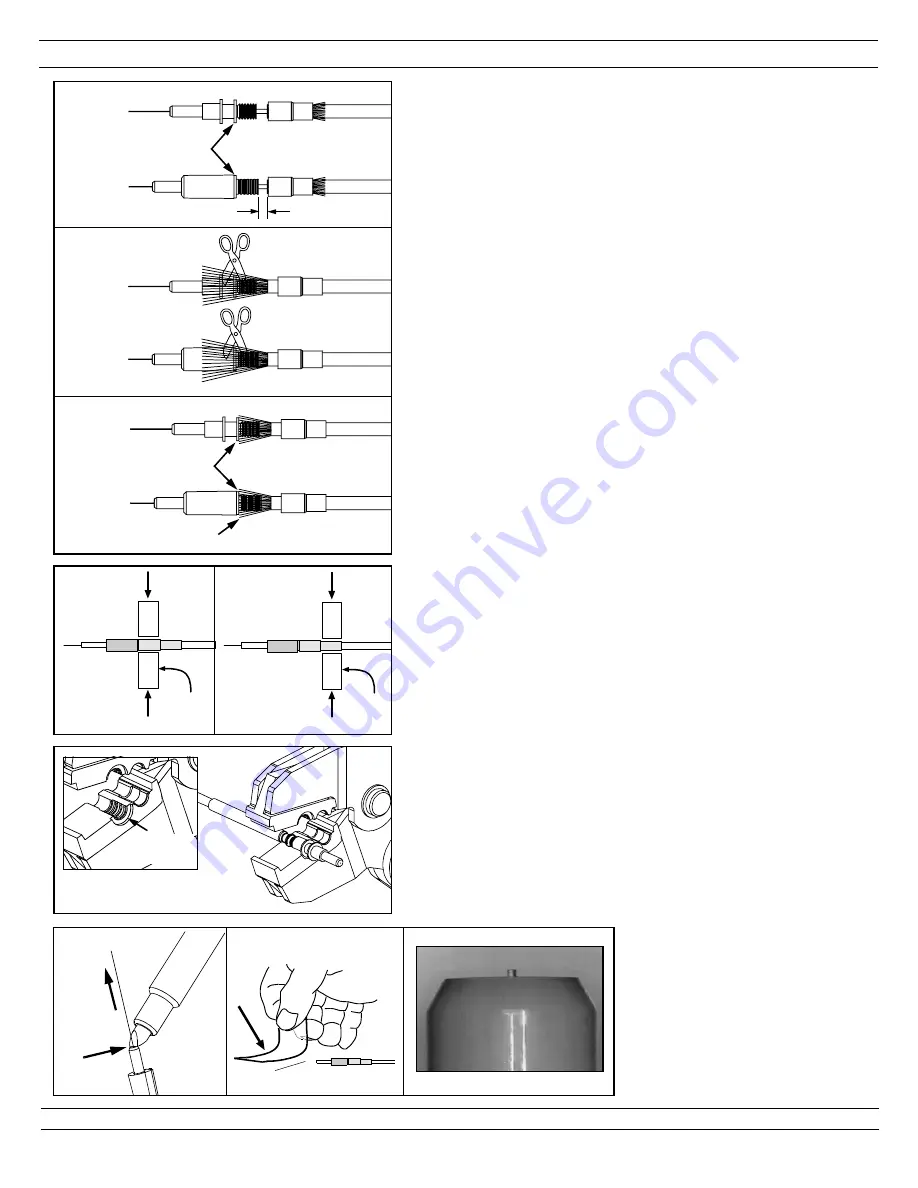

3.4.1 Slide the crimp sleeve back, freeing the aramid

yarn. The cable jacket should nearly touch the rear

of the backbone of the ferrule assembly.

Note: Do not press the cable jacket forward to

touch the rear of the backbone. There should be

a gap between the jacket and backbone.

3.4.2 With the appropriate strength member (aramid

yarn) cutters, cut the aramid yarn even with the

flange.

3.4.3 Flare the aramid yarn

evenly

around the perimeter

of the grooved area of the backbone of the ferrule

assembly.

For 2.0mm/1.6mm jacketed cable

, use

tweezers for best results.

3.4.4 Slide the crimp sleeve over the backbone, trapping

the aramid yarn between the crimp sleeve and the

grooved area of the backbone.

3.4.5

For 3.0mm jacketed cable:

Make sure the crimp

sleeve is seated against the flange of the backbone,

crimp the large end of the crimp sleeve using a

.151" hex of the FCRP5 Universal Crimp Tool.

Using the .128" hex of the crimp tool, crimp the

small end of the crimp sleeve over the cable jacket.

3.4.6

For 2.0mm/1.6mm jacketed cable:

Align the front

edge of the crimp sleeve with the front recessed

edge of the die pocket of the FLPT crimp tool.

Note:

The front recessed edge of the crimp die

pocket is the side with the ribs.

Make sure the crimp sleeve is seated against the

backbone and crimp the crimp sleeve.

3.4.7 Repeat for the second ferrule assembly.

3.5 CLEAVING

3.5.1 Using a cleave tool, gently make one small score

mark across the bare fiber just above the endface of

the ferrule. Pull the fiber away from the ferrule and

discard it on one of the sticky tabs provided. A

short stub of fiber protruding from the tip of the

ferrule should be visible when viewed through the

FLOUPEX10 Eye Loupe.

3.5.2 Repeat for the second ferrule assembly.

Page 5 of 8

3.4.1

FLARE ARAMID

YARN EVENLY

FLANGE

GAP

3.4.3

JACK

PLUG

JACK

PLUG

JACK

PLUG

3.4.2

FLANGE

FIRST

CRIMP

SECOND

CRIMP

3.4.5

.151" HEX

DIE

.

128" HEX

DIE

3.4.5

3.4.6

Recessed

Edge

Crimp die

1. SCORE

2. PULL

FIBER

3.5.1