For Technical Support: www.panduit.com/resources/install_maintain.asp

INSTALLATION INSTRUCTIONS PN256D

5. CURING HEAT SHRINK TUBING

For 2.0mm/1.6mm jacketed cable only

.

5.1

Turn the heat adjustment knob of the heat shrink curing

tool so the white line is centered in the notch.

5.2

Turn heat shrink curing tool “on”. (The temperature of the

hot air stream at the nozzle should be 220°F - 240°F)

5.3

Hold onto the connector and support the cable.

5.4

Bring the heat shrink tubing into the hot air stream. Hold

the heat shrink tubing about 1/2" away from the nozzle.

Rotate the connector for 20-30 seconds so that the heat

shrink tubing is completely cured onto the jacket.

5.5

Remove the connector from the hot air stream.

5.6

Turn heat shrink curing tool “off”.

Page 7 of 8

6. JACK ASSEMBLY

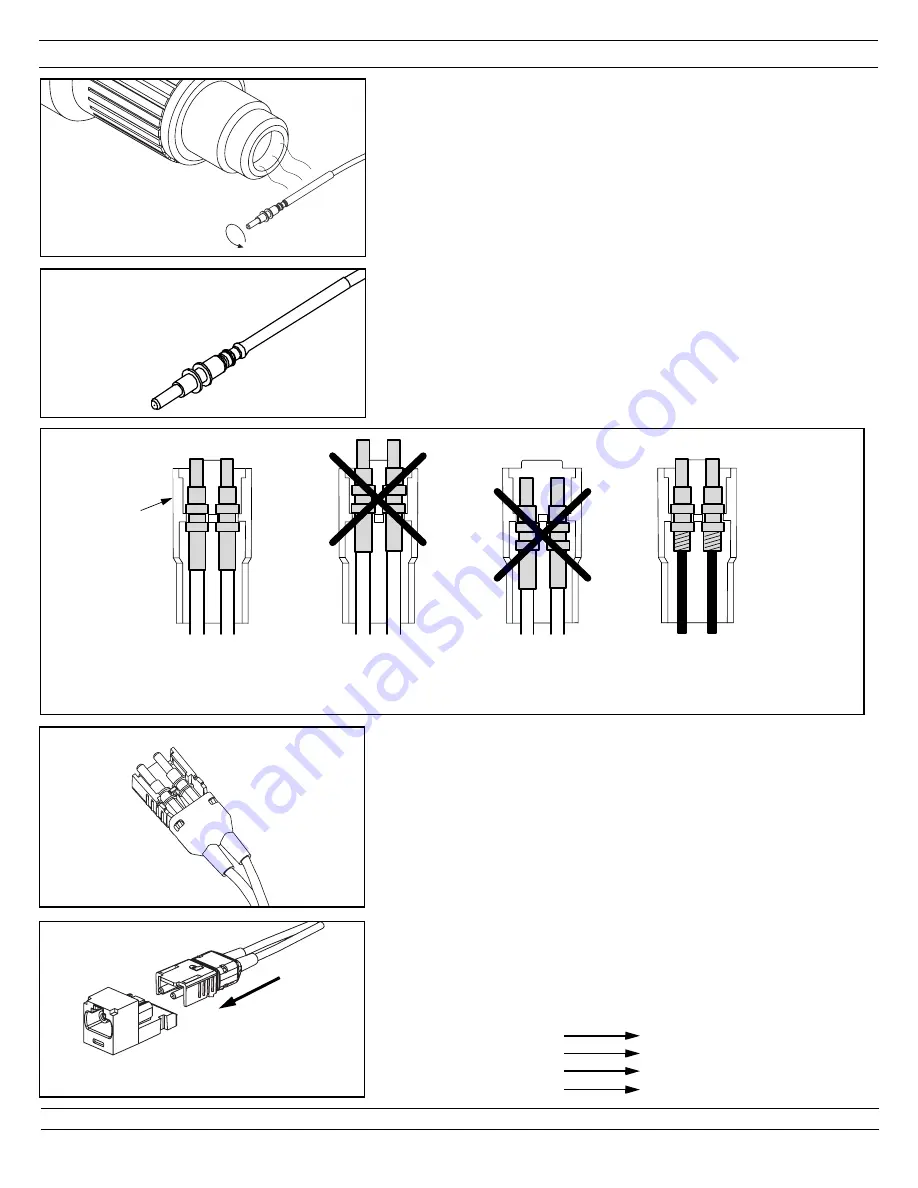

6.1

Turn the snap-on jack cover over in your hand so that the ‘A’

and ‘B’ marks inside the cover are facing you and are

upright. Then, place each ferrule assembly in the jack

cover. Maintain proper orientation of the fiber runs by using

the ‘A’ and ‘B’ marks to your specific wiring convention.

6.2

Slide the boot up to the cover until the holes of the boot lock

on to the tabs of the cover.

6.3

Next, position snap-on jack cover behind the jack housing.

The ferrules should start to enter the split sleeves which are

held within the jack housing. Slide cover forward, aligning

the rails in the cover and jack housing.

Note: If you are using

O

PTI

-J

ACK

Keyed connectors,

verify that plug mates with intended jack.

6.1

SLIDE

FORWARD

6.3

5.5

YES

Jacketed Cable

NO

Ferrules are located

too far forward

NO

Ferrules are located

too far backward

YES

Buffered Cable

6.1

Jack Cover

5.4

FJEPGM5CWBL

FJEPGM5CXRD

FJEPGM5CYOR

FJEPGM5CZYL

FJJGM5CWBL

FJJGM5CXRD

FJJGM5CYOR

FJJGM5CZYL