For Technical Support: www.panduit.com/resources/install_maintain.asp

INSTALLATION INSTRUCTIONS

© Panduit Corp. 2012

FS036B

Page 5 of 7

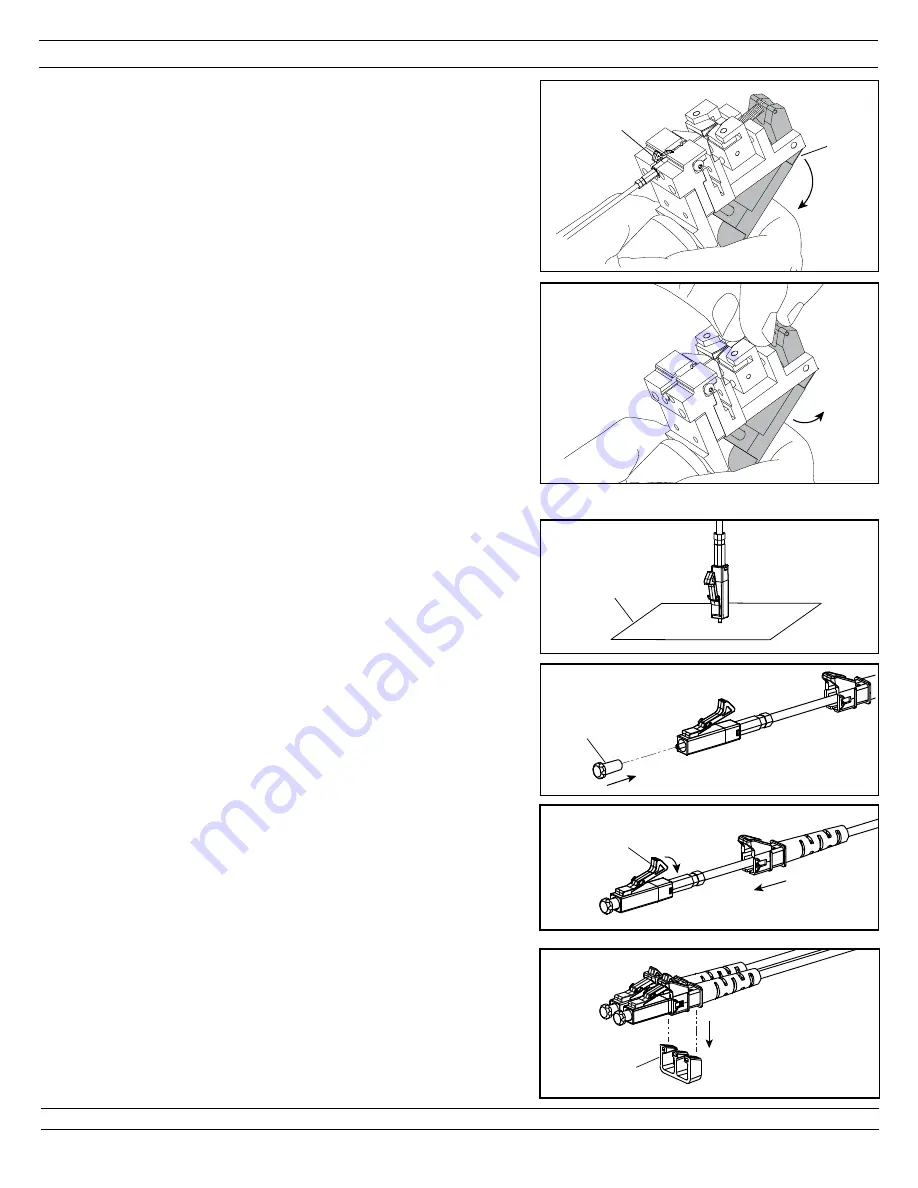

4.2

Cleave Fiber

4.2.1 DO NOT hold connector during cleave. To prevent fiber

protrusions, refrain from holding the latched connector

during the cleave process. DO NOT pull on the cable or let

cable weight pull on the connector. Hold cleave tool with

connector side up and SLOWLY press lever (3-5 sec) to

cleave fiber. Supporting the cable prevents potential

damage to the tool. To prevent fiber scrap from retracting

onto ferrule end face, DO NOT release lever at this step.

Note: The slow actuation of the trigger is critical. In order for the

diamond blade to do its job as a flaw initiator, the tool operator

must depress the trigger slowly (3-5 sec). Depressing the

trigger too quickly will crash the diamond into the glass fiber and

may break the blade.

4.3

Remove Connector and Fiber Scrap

4.3.1 With cleave tool lever still depressed, unlatch and remove

connector from cleave tool.

4.3.2 Release lever and remove fiber scrap.

Note: Removing the connector before releasing the lever allows

the blade to return to its correct position without contacting the

fiber scrap.

4.4

Apply Dust Cap and Install Boot Assembly

4.4.1

D

o not touch ferrule endface after cleaving. If endface

becomes contaminated, clean by pressing onto adhesive

side of FSTY tape. Multiple cleaning cycles may be

required.

4.4.2 Apply dust cap onto ferrule.

4.4.3 Fully deflect connector latch and slide boot assembly,

applied to cable in step 2.1, onto connector until it snaps

into place over the latch.

4.5

Attach Duplex Clip (Optional)

4.5.1 For each PCF LC connector, insert square portion of

boot assembly into the top opening of duplex clip.

4.2.1

Lever

Connector

latch

4.3.2

FSTY

4.4.1

Dust cap

4.4.2

4.4.3

Connector

latch

4.5.1

Duplex

clip