INSTRUCTIONS FS149A

For Technical Support: www.panduit.com/resources/install_maintain.asp

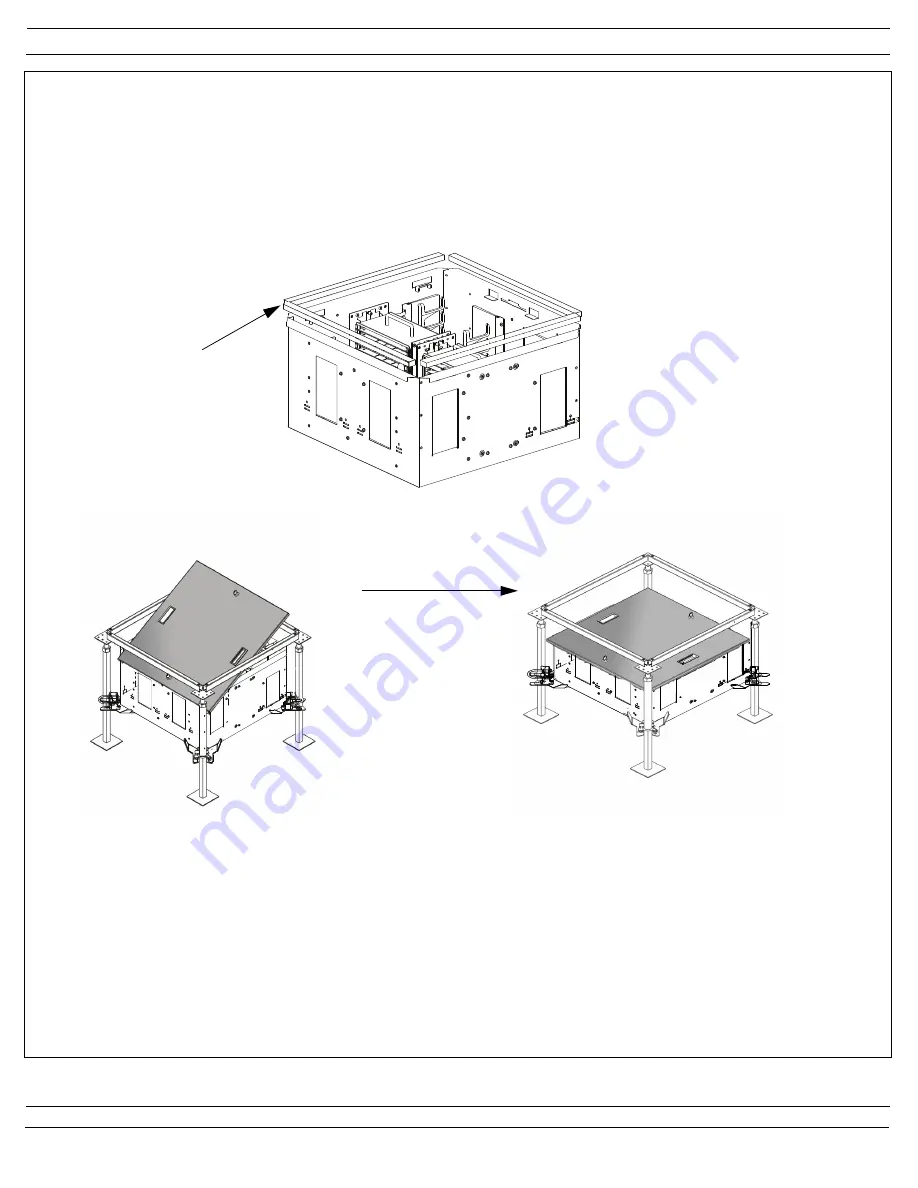

Figure 41

Figure 42

Once the seal has been suc-

cessfully attached, drop the

cover into the enclosure as

shown. (See Figures 41

through 42).

Option 1: HD Flex Zone Raised Floor Enclosure Cover FLEX-ZRFECG

Enclosure’s Cover Installation:

Attach Adhesive Foam Seal to the top of the enclosure (shown in Figure 40)

.

Foam Seal

Figure 40

Page 16 of 19

ADDITIONAL PRODUCTS SOLD SEPARATELY: