PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 21 of 36

Dec., 2007

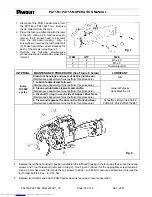

ERROR 13 - Detent sensor blocked or dirty

Detent sensor blocked or dirty

Help

Buzzer

Continue

POSSIBLE CAUSE:

Most likely, the tip collector is too full. The detent sensor lens may be blocked by the detent

cam, a foreign object, or the lens is dirty.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off". Remove the cable tie from the

jaw area of the tool and empty the tip collector. Press the

"Continue"

button and resume operation. If the error

message appears again, notify your maintenance department.

PREVENTION:

Always empty the tip collector before it is full (no more than 180 cycles). This will prevent debris

from re-entering the tool because the tip collector is too full. Keeping the tip collector clear will allow the cable ties an

area to exit the tool. The tool should also be cleaned periodically by your maintenance department.

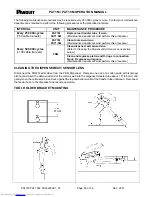

ERROR 14 - Internal regulator incorrectly set, low

Internal regulator incorrectly set, low

MENU

Buzzer

POSSIBLE CAUSE:

This error message appears if the PDM Dispenser internal regulator was adjusted incorrectly,

or the dispenser piston is not fully shifting.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off", and resume operation. If the

message remains, the system will not operate. Write down the message and notify the maintenance department.

PREVENTION:

Never adjust the PDM Dispenser internal regulator. Follow the maintenance schedule for regreasing

the piston.

ERROR 15 - Internal regulator incorrectly set, high

Internal regulator incorrectly set, high

MENU

Buzzer

POSSIBLE CAUSE:

This error message appears if the PDM Dispenser internal regulator was adjusted incorrectly.

CORRECTIVE ACTION:

Press the

"Buzzer"

button to turn the buzzer signal "off", and resume operation. If the

message remains, the system will not operate. Write down the message and notify the maintenance department.

PREVENTION:

Never adjust the PDM Dispenser internal regulator.

FUNCTIONAL MESSAGES

Functional messages notify the operator about component malfunction and/or maintenance requirements. Like the

error messages, the operator is alerted that an error has occurred by two types of signals: a buzzer signal (audible)

and the dispenser display (visual). The dispenser display will indicate the possible problem that has occurred.

Depending on the nature of the problem, the system may not become operational until the system is serviced.

electronic components distributor