PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 13 of 36

Dec., 2007

CABLE TIE INSTALLATION

1. Review and follow all of the

Safety Practices

on Pages 3-4, being certain to wear adequate eye protection.

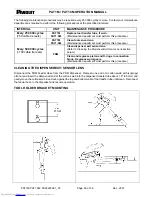

2. Verify that the Level 1 or Level 1B Operator Menu is displayed on the PDM Dispenser. The PAT1M and

PAT1.5M Tools can only cycle cable ties if one of the two Operator Menus (below), is displayed.

The Level 1 Operator Menu looks like this:

Loads:XX

XXXXXXX

Load

Unload

MENU

Exit

The Level 1B Operator Menu looks like this:

XXXXXXX

MENU

The Level 1B Operator Menu will only be displayed if the tool was actuated one or more times. Once the tool has

been actuated, the loading commands disappear ("Loads: X", "Load", and "Unload").

3. Grasp the tool with either hand, and slip the open jaws around the bundle or item to be cable tied.

NOTE:

Bundles should be routed at least 2" (51 mm) off the harness board for easy tool jaw access. However,

DO NOT allow the wire bundles to be forced into the jaw track. This will hinder the travel of the cable tie

around the jaws and could increase the possibility of a misfeed (cable tie tail will be blocked by wire

bundle when attempting to feed into cable tie head).

4. When the jaws are positioned at the preferred location for a cable tie, close the rear jaw by lifting the trigger (See

Figure 5 on Page 15). When the trigger is lifted to the highest point, the tool cycle will start. Hold the trigger

momentarily for proper cycling of the tool. The cable tie will be applied, tensioned and cut off.

5. At the completion of the cycle, release the trigger to open the rear jaw (See Figure 5 on Page 15). Relocate the

tool at the next desired cable tie location and repeat as required.

NOTE:

If a malfunction occurs, or a cable tie is not applied properly, then a buzzer will sound and an error

message will be displayed. Follow the "Help" instructions on display or refer to the

Error Messages

section on Pages 15-21 for more specific instructions.

HINT:

When applying several cable ties on a long bundle, the tool can be moved along the bundle to each

location, and cycled, without opening the jaws. This can be done by slightly relaxing pressure on the

tool trigger (but not enough to open the jaws), and then lifting the trigger to the highest point to cycle the

tool. With practice, this technique can be accomplished with minimal effort.

CABLE TIE INSTALLATION TECHNIQUES

Always use the following cable tie installation techniques to promote continuous trouble-free usage of the

PAT1M/PAT1.5M System. These techniques will prevent incomplete cable tie installations and system interruption.

•

Prevent severe bends or twists in the PHM Feeder Hose. This will prevent interference with the cable tie travel

to the tool and, in turn, reduce incomplete cycles.

•

Dress the wires to result in a compact bundle; .82" (21 mm) in diameter or less for the PAT1M Tool, and 1.31"

(33 mm) in diameter or less for the PAT1.5M Tool. This will prevent loose cable ties or cable ties that do not stay

on the bundle.

•

Hold the tool perpendicular, in both directions, to the bundle or item to be cable tied. Left to right, and top to

bottom. This will prevent loose cable ties and cable ties that are not cut off flush to the head.

electronic components distributor