PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 26 of 36

Dec., 2007

The following maintenance procedures may be required every 250,000 cycles or more. Contact your maintenance

department as required to perform the following procedures at the prescribed intervals.

INTERVAL UNIT

MAINTENANCE

PROCEDURE

Every 250 000 cycles

(=50 cable tie reels)

PAT1M

PAT1.5M

Replace tool transfer tube, if worn.

(Maintenance department must perform this procedure.)

PAT1M

PAT1.5M

Clean tool sensor lens.

(Maintenance department must perform this procedure.)

Clean dispenser exit sensor lens.

(Refer to

Cleaning the Dispenser Exit Sensor Lens

section

below.)

Every 500 000 cycles

(=100 cable tie reels)

PDM

Clean and regrease piston and O-rings in connection

block. Regrease worm gears.

(Maintenance department must perform this procedure.)

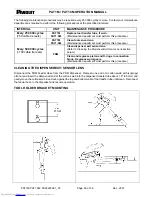

CLEANING THE DISPENSER EXIT SENSOR LENS

Disconnect the PHM Feeder Hose from the PDM Dispenser. Dampen one end of a cotton swab with isopropyl

alcohol and insert the dampened end of the cotton swab into the dispenser transfer tube about 1.5" (38 mm) and

gently move the cotton swab in and out, against the top and bottom walls of the transfer tube until clean. Reconnect

the feeder hose to the dispenser and resume operation.

TOOL HOLDER BRACKET MOUNTING

electronic components distributor