PAT1M / PAT1.5M OPERATION MANUAL

PAT1M/PAT1.5M: PA22222A01_03

Page: 6 of 36

Dec., 2007

OTHER SPECIFICATIONS

ITEM

DESCRIPTION

Peak Sound Level during cycle

76 dBA (average)*

PAT1M/PAT1.5M Tool Vibration

Less than 2.5 m/s

2

**

* As measured in accordance with ISO 11202: 1995 (E).

** As measured in accordance with ISO 5349.

INSTALLATION

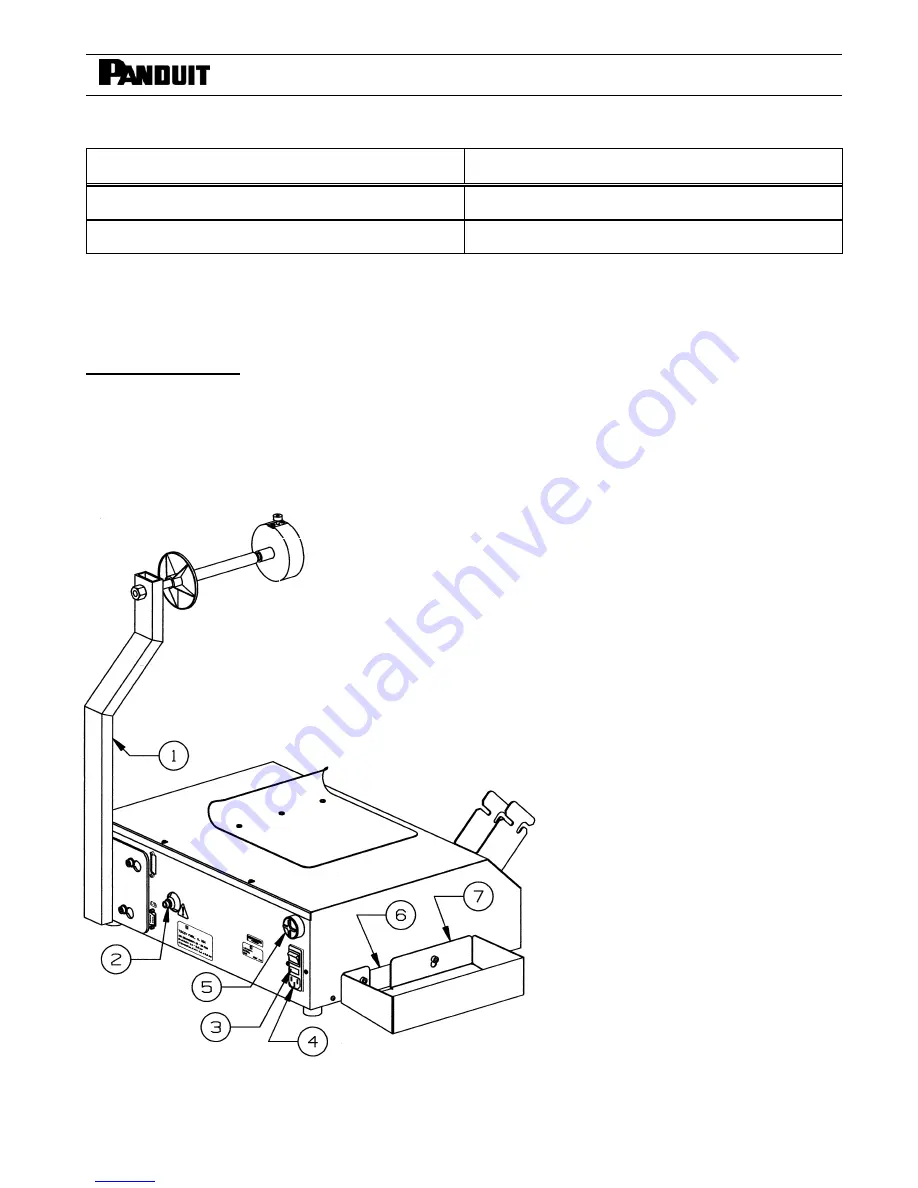

DISPENSER MOUNTING

After unpacking the components, mount the carrier strip scrap bin (See Figure 1) on the left side of the dispenser by

positioning the larger holes in the bin over the cap screws on the dispenser, and sliding the bin down. Attach the tool

holder bracket (See Figure 2 on Page 7) to the front of the dispenser by positioning the larger holes in the tool holder

bracket over the cap screws on the

dispenser, and sliding the bracket

down into position. Refer to Page 26

for alternate mounting to walls, carts

or bench tops. Always position the

dispenser in the work area so there

are no severe bends or twists in the

PHM Feeder Hose.

SYSTEM CONNECTION

1. Connect the female quick

disconnect end of the air hose

and filter/regulator assembly to

the male air inlet on the back of

the dispenser (See Figure 1).

2. Connect the filter/regulator to the

main (NON-LUBRICATED) air

supply and set the filter regulator

at 65 PSIG for optimum

performance (Refer to the

Air

Supply

section on Page 5).

3. Verify installation by reviewing the

Installation Checklist

section

below.

PDM DISPENSER

COMPONENT LIST

1.

XMR Reel Mount Assembly

2.

Male Air Inlet

3.

Power Switch/Fuse Holder

4.

Power Cord Receptacle

5. Buzzer/Volume

Adjustment

6.

Carrier Strip Exit Chute

7.

Carrier Strip Scrap Bin

Fig. 1

electronic components distributor