PAT 4.0 AUTOMATIC CABLE TIE INSTALLATION SYSTEM

ELECTRONIC INTERFACE USER MANUAL

© Panduit Corp. 2017

PA28091A01_02

Page

8

of

9

2-2017

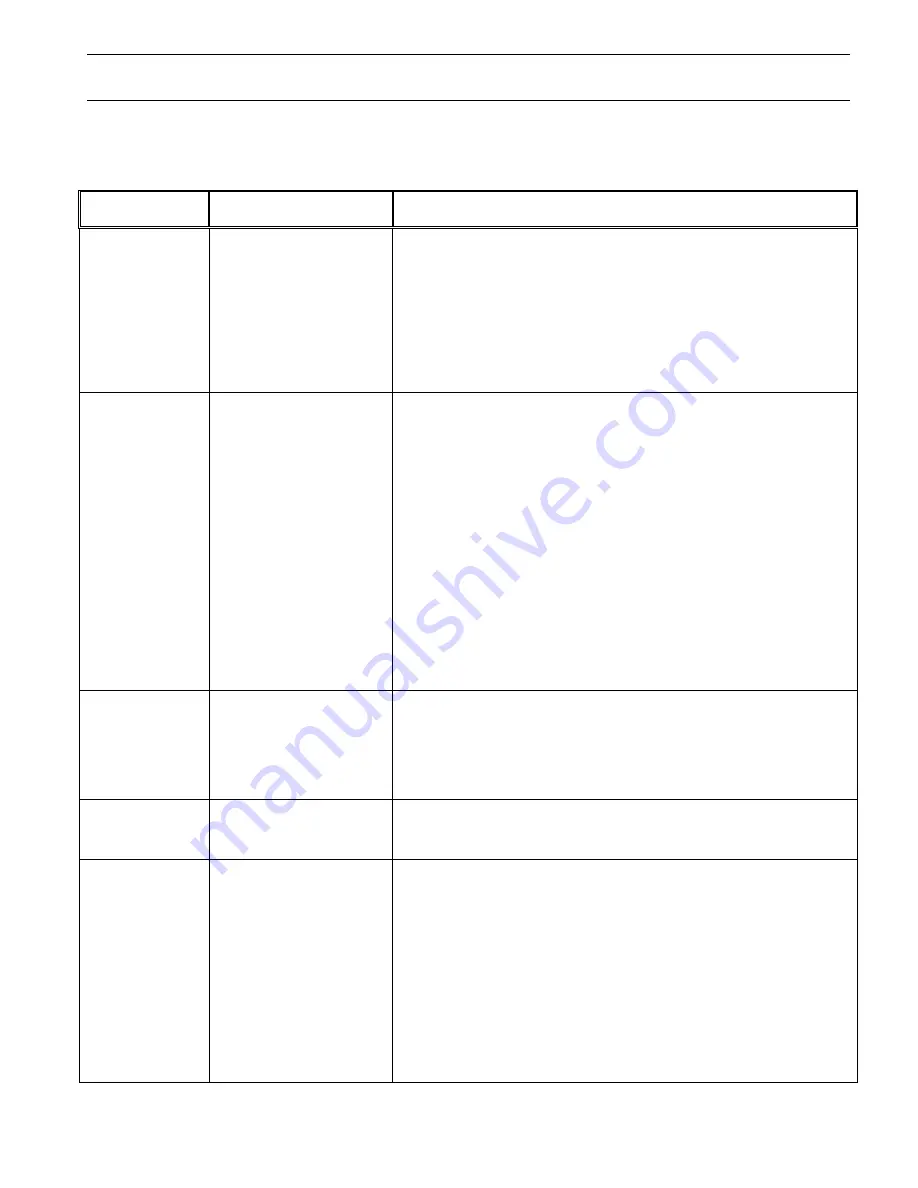

Cable Tie Dispenser Display for Errors & Corrective Action

Dispenser

Display

Possible Cause

Corrective Action

“Dispenser jam -

check tie loading”

Dispenser rotary receiver

did not advance next tie

into position; due to bent

cable tie, or jam of carrier

strip in strip exit chute.

{

PDS-EI

Only

: Or Cable

Tie Reel Moved off of Reel

Pivot Disk on Dispenser

Frame}

1.

Press "Buzzer" button to turn buzzer off.

2.

Check rotary receiver and connection block for jammed cable tie, and

check for jam in carrier strip exit chute.

3.

Press "Unload" to back loose cable ties from rotary receiver & un-jam.

4.

Cut excess carrier strip and any distorted or damaged cable ties from

cable tie reel.

5.

Close Cover and perform loading procedure.

“Out of ties or tie

in dispenser”

A. Reel empty; dispenser

out of cable ties.

B. Reel not empty; tool

cycled without enough

cable ties loaded,

C. Cable tie prevented

from leaving dispenser.

A. 1. Press "Buzzer" button to turn buzzer off.

2. Press "Continue"; then "Menu" to bring up "Reset" display.

3. Press "Reset load" to bring up "Load, Unload, Menu" display and

perform the standard reloading procedure.

B. 1. Press "Buzzer" button to turn buzzer off.

2. Press "Continue"; then "Menu" to bring up "Reset" display.

3. Press "Reset load" to bring up "Load, Unload, Menu" display.

4. Press "Load" to load one (1) cable tie and resume operation.

C. 1. Disconnect air hose and feeder hose from dispenser.

2. Remove cable tie from Dispenser connector block, if present. (if tie

does not come out freely, turn dispenser off / then on again, to reset

rotary receiver position). If not able to remove a stuck tie, notify your

maintenance department.

3. After Cable Tie is removed, reconnect air hose and feeder hose to

dispenser.

4. Press "Continue"; then "Menu" button to bring up "Reset" display.

5. Press "Reset load" to bring up "Load, Unload, Menu" display.

6. Press "Load" to load one (1) cable tie and resume operation.

“Cover is open, no

tie loaded”

A. Cover was open when

"Load" was pressed.

B. Cover was open when

tool was cycled.

A. 1. Press "Buzzer" button to turn buzzer off.

2. Close Cover.

3. Resume loading procedure.

B. 1. Press "Buzzer" to turn buzzer off.

2. Close Cover.

3. Press "Load" to load one (1) cable tie and resume operation.

“Check for low air

pressure” (

or

“high”)

A. Incoming air pressure

too low or too high.

B. Air not connected.

A. 1. Press "Buzzer" button to turn buzzer off. 2. Set air pressure 65-85

PSIG (4.5-5.8 bar), with max. 10 PSIG (0.7 bar) drop.

B. Connect air to PDM.

“Tie stuck in exit

sensor”

or

“Blocked or dirty

exit sensor”

or

“No exit sensor

seen – service

tool soon”

Exit sensor in dispenser is

obstructed by a cable tie or

excess debris (dirt, grime).

or

Cable tie in feeder hose

when cycle started.

or

Exit sensor in dispenser is

not functioning properly.

1. Press "Buzzer" button to turn buzzer off.

2. Disconnect feeder hose from dispenser and remove tie from dispenser

connector block if present (if tie does not come out freely, turn

dispenser off / then on again, to reset rotary receiver position). If not

able to remove a stuck tie, notify your maintenance department.

3. Reconnect feeder hose, and resume operation.

4. If tie is not found, reconnect feeder hose and follow the same

Corrective Action for "Tie in hose - press air burst" error to remove

the cable tie from the system.

5. If the same error is repeated, clean the dispenser exit sensor lens and

resume operation.

6. If the same error is still repeated, maintenance is required to replace the

exit sensor.