For Technical Support: www.panduit.com/resources/install_maintain.asp

INSTRUCTIONS V00028FG REV 11

Page 3 of 4

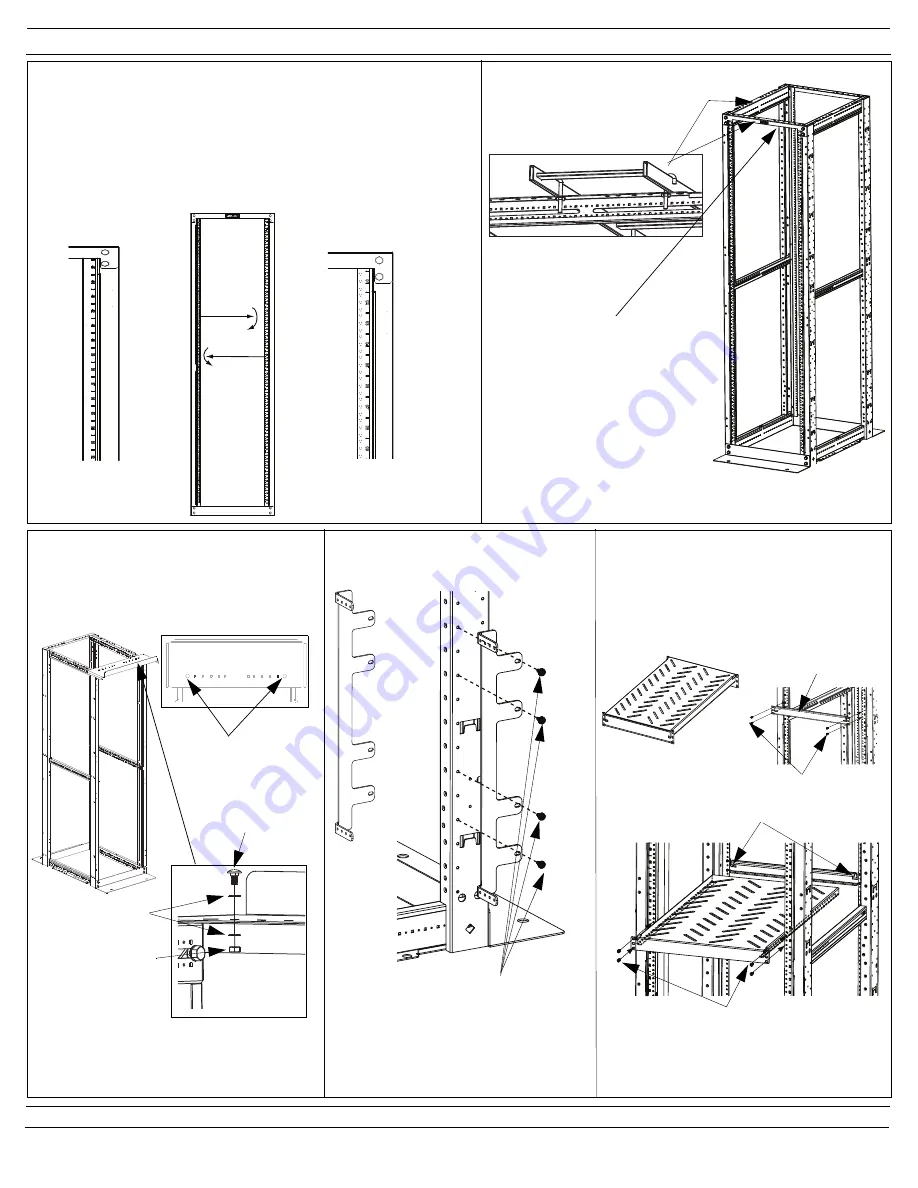

Flippable EIA Mounting Rails

The rack is shipped with rails in a numbers-up orientation. The rails can

be flipped to read in a numbers-down orientation by moving 1 right rail and

1 left rail in tandem. Remove (3) 5/16"-18 X 3/4" Mounting Bolts on each

rail. Then flip

right

rail so that numbering reads down and bolt to

left

side

of assembly using bolt orientation shown. Then flip

left

rail so that num-

bering reads down and bolt to

right

side of assembly using bolt orienta-

tion shown.

Numbering-Up

Orientation

Numbering-Down

Orientation

Use J-Bolt mounting holes for

securing ladder rack to the 4-post

rack.

R4PWF

Apply Antioxidant Paste to painted surfaces that

the 3/8" paint piercing washers will come in con-

tact with.

Mounting Locations

Fig, 1

CVPPB-

Zero RU Bracket- to mount 1RU

EIA 19" copper and fiber patch panels to the

side of rack posts.

CVPPB

Secure to desired hole location

using #12-24 screws

Side of post installation

RSHLF-

Shelf for 30" Deep rack

RSHLF23-

Shelf for 23" Deep rack

RSHLF36-

Shelf for 36" Deep rack

Mount bracket to

desired RU in rear of

rack

Slide shelf into slots in rear mounting bracket

Secure with (4) #12-24 screws

#12-24 screws

Shelf

Secure the waterfall as shown in Fig. 1 using

provided hardware.

(2) 1/4-20 bolts

(4) Paint

piercing washers

(2) 1/4-20 nuts

Note:

Shelf load rating is 275 lbs. when rails are

spaced a minimum of half the shelf depth.

Note:

Shelf is designed to support large net-

working equipment in combination with sup-

plied equipment mounting flanges.

J-Bolts up to 3/8" in diameter may

also be installed directly to the top

angle without interference with the

top mounting RU space.