BA_PH_680-200_EN_11-22.docx

22

4.5.4

Parallelism of the rip fence

Regularly check the parallelism of the fence by measuring the front and rear of the machine table. Even a slight

deviation of 1 to 2 degrees can press the workpiece against the saw blade in such a way that it jams. Then it

can be caught by the rising teeth and trigger a kickback. Ideally, the distance of the fence to the rear (in the

direction of the rising teeth) is approx. 0.2 mm higher than in front of the saw blade.

Danger of kickback due to ejecting workpieces! The distance of the fence in front of the saw

blade must never be higher than at the rear in the area of the rising teeth.

Clear indications that the parallelism of the fence is no longer correct are sluggishness of the workpiece when it

is fed, a strong noise development and burn marks on the workpiece. If your fence has been misaligned, please

contact our customer service (phone number: 0049 - 7571 / 755-0).

4.5.5

Cutting off small pieces on the rip fence

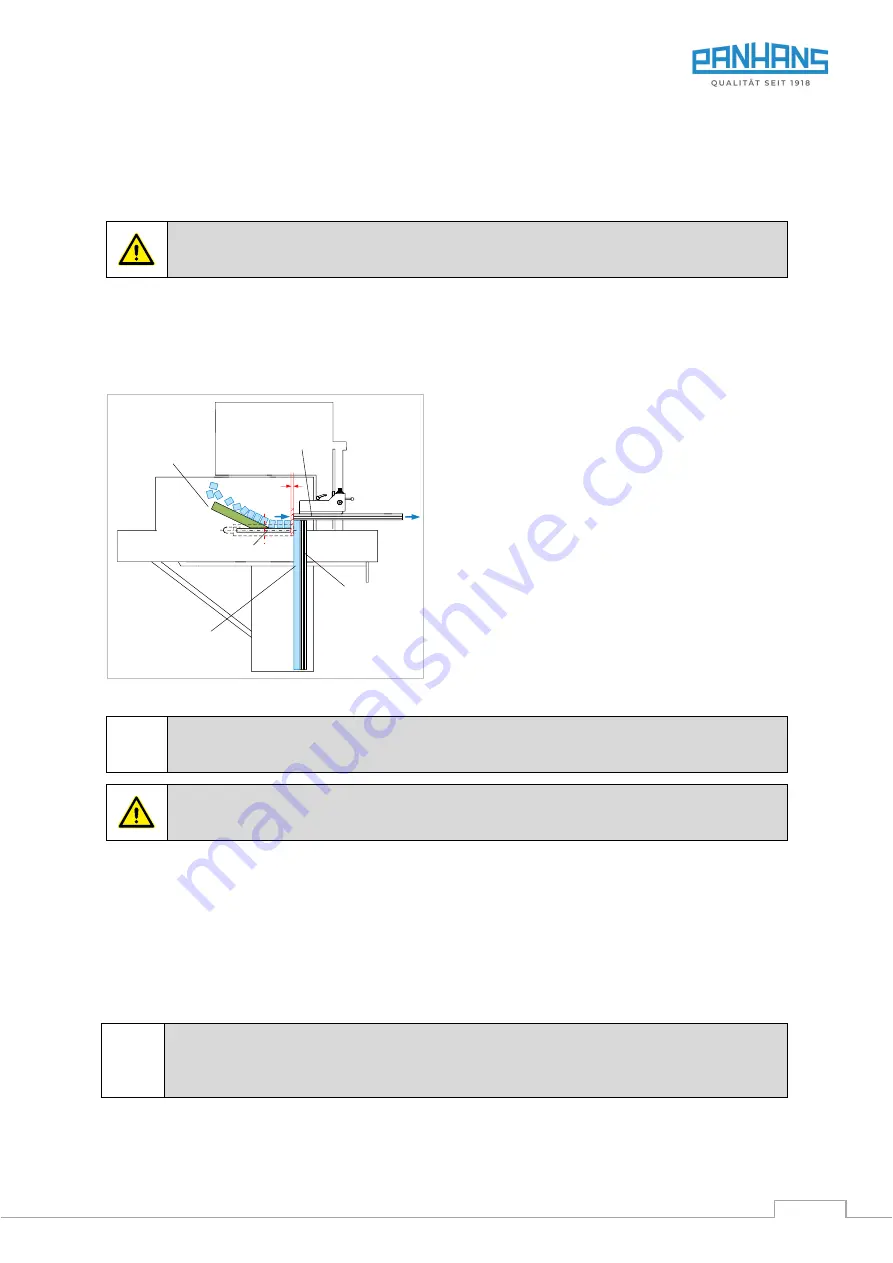

Figure 5: Fixing the deflector wedge on the table

If you are using the rip fence to cut many smaller pieces of

identical dimensions from a long piece (which rests

against the cross-cut fence), it is important to prevent cut

pieces from jamming between the fence and the saw

blade and being caught by the rising teeth.

➔

To do this, move the rip fence backwards towards the

operator's side and fix it so that there is enough space

between the fence and the front edge of the saw blade

for the retraction (see

Figure 5).

➔

Fix an additional deflector wedge (see

Figure 5) auf

on the table top so that small parts that have already

been cut off cannot be caught by the rising teeth and

flung upwards.

Important: The deflector wedge must be fitted so far towards the operator's side that the

cut-off parts are already deflected shortly before the centre of the saw blade.

Danger of kickback due to ejecting workpieces! Never remove already cut parts by hand and

fix a deflector bar on the machine table.

4.6

Special Characteristics of Guards Made of Polycarbonate (Plexiglas)

Polycarbonate guards require special attention if they are to protect against possible flying tool parts (e.g. in

case of tool breakage of cutters or saw blades).

Polycarbonate guards must therefore be checked regularly for deep scratches, cracks, bulges or cloudiness

(visual inspection). If corresponding damage becomes apparent, the protective device must be replaced imme-

diately, as the required protective capability is no longer given.

Do not use oils, fuels or solvents to clean and maintain polycarbonate protective devices. Do

not use aggressive or toxic industrial cleaners that can damage the windows or bonding. Under

no circumstances may nitro thinner be used. The cleaner must be free of hydrocarbons.

Saw Blade

Rip Fence

Workpiece

Deflector Wedge

Cross-cut Fence

Retraction