7

4.

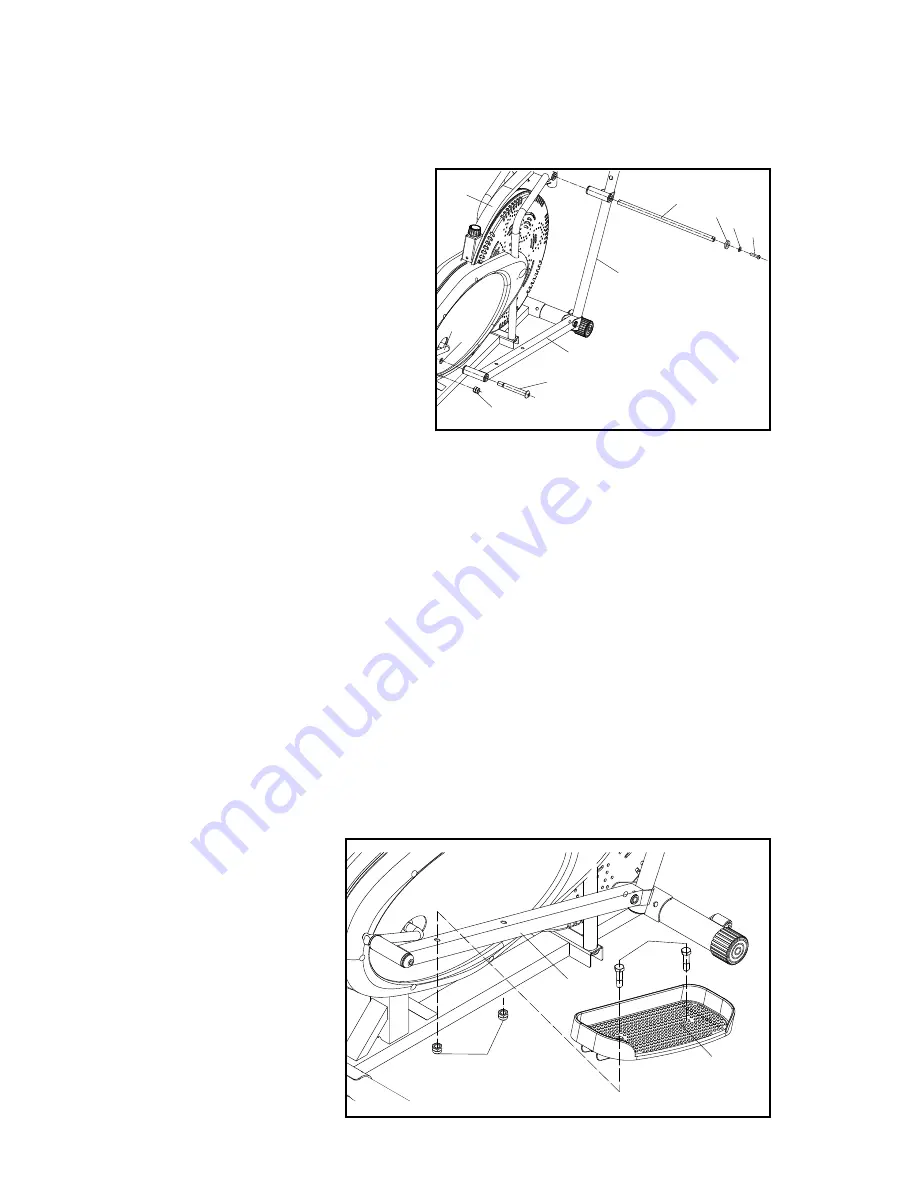

. .Attach .right .

Pedal

(#11)

.to .

Right Pedal

Tubing (#6R).

.

Use .two .

3/8” x17/8”

Bolts (#44)

.and .

two .

3/8” Nuts (#45).

.

Repeat .these .steps .on .

left .side . .(See .Fig .3)

NOTE:

Use .WD40 .or .any .tool .lubricant .to .reduce .friction .when .screwing .in .the .

Pedal Hinge Bolt

.to .the .

Crankshaft.

.The .bolt .may .become .tight .at .times .and .

may .even .feel .like .it .will .no .longer .screw .in . .However, .making .sure .screw .is .

properly .lubricated .and .performing .occasional .back .and .forth .twists .to .the .bolt .

will .ensure .that .it .goes .through .with .more .ease . .

NOTE:

.Both .

Pedal Hinge Bolts

will .not .have .the .same .screw .pattern .and .both .the .left .and .right .sides .will .tighten .

using .opposite .tightening .directions .

2.

. .Insert .the .

Handle Bar Shaft (#12A)

through .the .

Coupler Bar

.of .either .the

right .or .left .side . .Making .sure .the .

Handle Bar Shaft (#12A)

.goes .

all .the .way .through .the .main .

frame .and .reaches .the .outer .end .

of .opposite .

Coupler Bar.

Make .

sure .to .secure .

Handle Bar Shaft

.

by .using .the .

Hinge Screw (#57),

Sharp Washer (#49)

.and .

Spring

Washer (#52)

.by .tightening .

the .

Hinge Screw

.at .each .end .

simultaneously .with .the .2 .

Small

Allen Keys

.provided . .

3.

. .Now .to .complete .assembly .of .the .arm .bar, .insert .a .

Pedal Hinge Bolt (#12B)

.

through .the .

Pedal Tubing (#6R for right side, #6L for left side).

.Screw .the .

Pedal Hinge Bolt

.using .the .

Large Allen Key

.provided, .into .the .

Crankshaft,

which .is .already .installed .within .the .Panther’s .main .frame . .Secure .the .

Pedal

Hinge Bolt

.at .the .inner .end .with .a .½” .

Spring Nut (#48)

.and .a .½” .

Spring

Washer (#51).

.(See .Fig .2)

Steps 2 through 4

will .detail .assembly .of .

Pedals

and

Coupler Bars

. .Repeat .these .

steps .on .each .side .(Left .and .Right) .before .moving .on .to .Handle .Bar .assembly .

Fig 3

44

6

45

11

Fig 2

27

12B

48

51

6R

4

12A

49

57

52

1

Summary of Contents for Elliptical

Page 1: ...Panther_BilingualMAN_TP_ENG SPAN_V1_110802 ...

Page 2: ......