EM

BR

OI

D

ER

Y

B

AS

IC

S

1

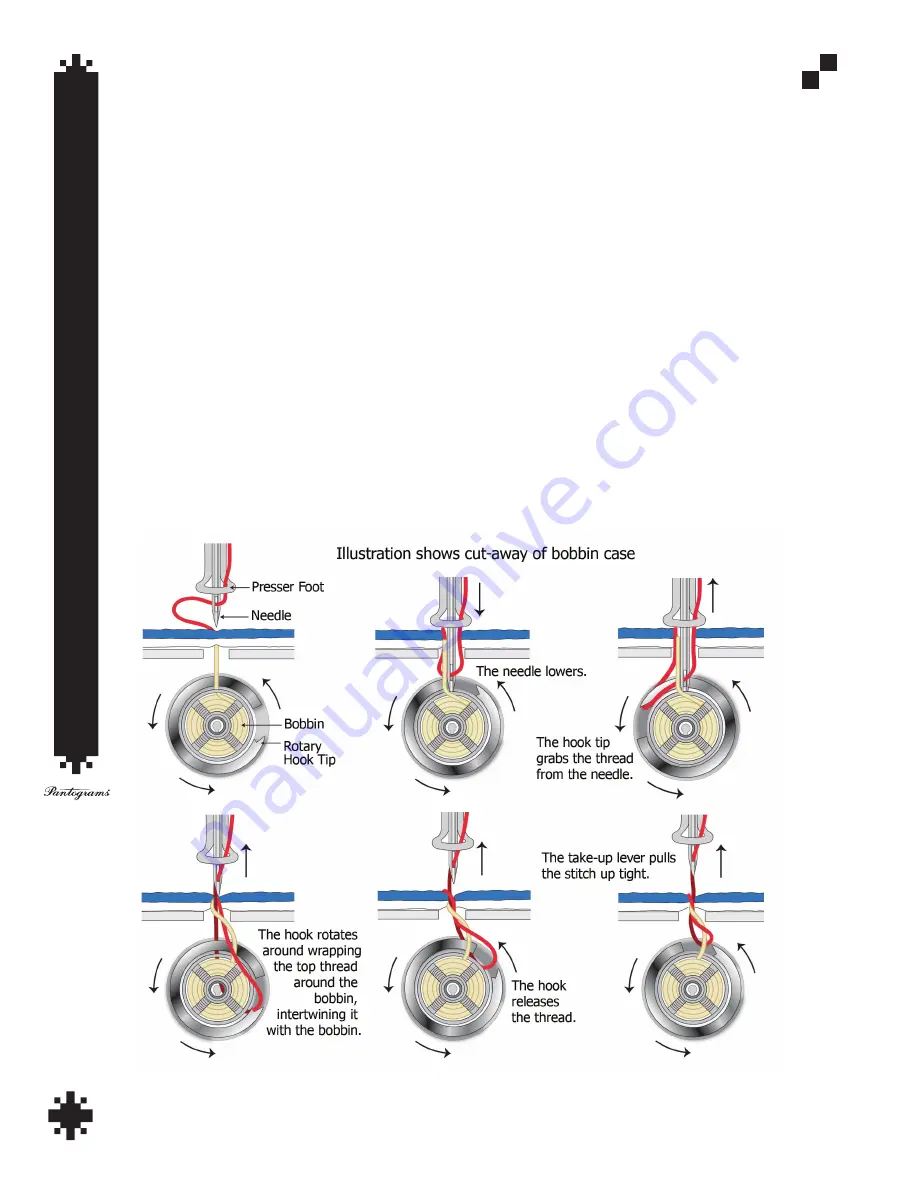

Stitch Formation

Knowing the fundamentals of a stitch helps you solve sew out problems, perform machine maintenance and

avoid downtime. Embroidery machines create a straight stitch called a 301 lock stitch using a rotary hook and

bobbin. The rotary hook, also known as the hook assembly, consists of two parts: the hook basket (where the

bobbin case sits) and the hook body (which rotates around the basket). The hook body has a hook tip, which

is two overlapping pieces of metal that grabs the thread.

A stitch forms when the top thread and the bottom (bobbin) thread interlock after passing through a piece of

fabric. First, the eye of the threaded needle penetrates the fabric. The needle has a groove built into the front

of the shaft that allows the thread to easily follow the eye past the layers of fabric. Then, as the needle de-

scends to its lowest position, the thread tightens. As the needle starts to move up, the thread on the back of

the needle doesn’t pull back immediately due to the friction of the fabric and creates a small loop. At that very

instant, which is set by the “timing” of the machine, the rotary hook comes around and passes its tip between

the needle and the loop of thread.

As the needle continues to move up from the fabric, the rotary hook grips the loop as it spins. The edge of the

hook (which is polished extremely smooth) pulls the loop down and around the thread coming from the bob-

bin. The rotary hook continues a full revolution (counter clockwise as one faces the machine) as the needle

reaches the uppermost point. The rotary hook releases the thread as the take-up arm pulls up any excess

slack and tightens the formed stitch. The needle starts down again and creates another stitch cycle.

The process happens at up to 1200 stitches per minute with the rotary hook actually spinning at twice the

speed of the needle, making two revolutions for every penetration of the needle. With operations this fast, one

can understand why the rotary hook timing and the needle clearance are so precise and why hook faces are

finely polished. In addition, it is necessary to oil the rotary hook every four hours when the machine is run-

ning. See Machine Basics section for proper oil maintenance.

Summary of Contents for GS1501

Page 30: ...GETTING STARTED 28 ...

Page 31: ...GETTING STARTED 29 The Control Panel Display ...

Page 62: ...EMBROIDERY BASICS 28 Notes ...

Page 64: ...MACHINE BASICS 2 ...

Page 65: ...MACHINE BASICS 3 ...

Page 70: ...MACHINE BASICS 8 ...

Page 71: ...MACHINE BASICS 9 ...

Page 78: ...MACHINE BASICS 16 Notes ...