EM

BR

OI

D

ER

Y

B

AS

IC

S

11

Tension

Bobbin Tension

To test the bobbin tension, take the bobbin thread out of the pigtail. Hold the bobbin case in your left hand

and pinch the thread near the case with your right thumb and index finger. With your right hand, give the bob

-

bin a quick jerk. The thread should unwind and be pulled out of the bobbin by its own weight. There should

be about an inch and a half drop from the fingers to the bobbin. The drop may vary depending on the amount

of force applied by the wrist action. The key is consistency. If your bobbin drop is four inches and sews out

with the correct tension then use four inches as your guide. The bobbin thread should fall smoothly, without

resistance. If the bobbin case hardly moves the tension is too tight, if it drops a lot, the tension is too loose. If

the bobbin pops out of the case, the adjustment may be too loose or your bobbin drop too violent. The bobbin

tension test technique may take some practice to master.

Machine Tension

To check the proper tension on your machine, embroider any column fill design that uti

-

lizes all the needles on your machine. When finished, turn the embroidery over and look

at the underside. In the column fill areas, you should see one-third top thread on the side,

one-third bobbin thread in the middle and one-third top thread on the other side. If the

design doesn’t fit this formula, the tension needs to be adjusted.

Factors Influencing Thread Tension

Thread Color

The different color dyes affect the texture of the thread which affects how

smoothly it glides through the machine.

Thread Weight

Changing the thread weight will require adjusting the tension.

Machine Speed

The varying speed of the machine may affect the tension, adjust the

tension according to the speed most commonly used.

Needle Size

Thread friction from smaller eye needles need its tension adjusted.

Dust & Lint

Excess dust and lint along the thread path can affect the thread tension.

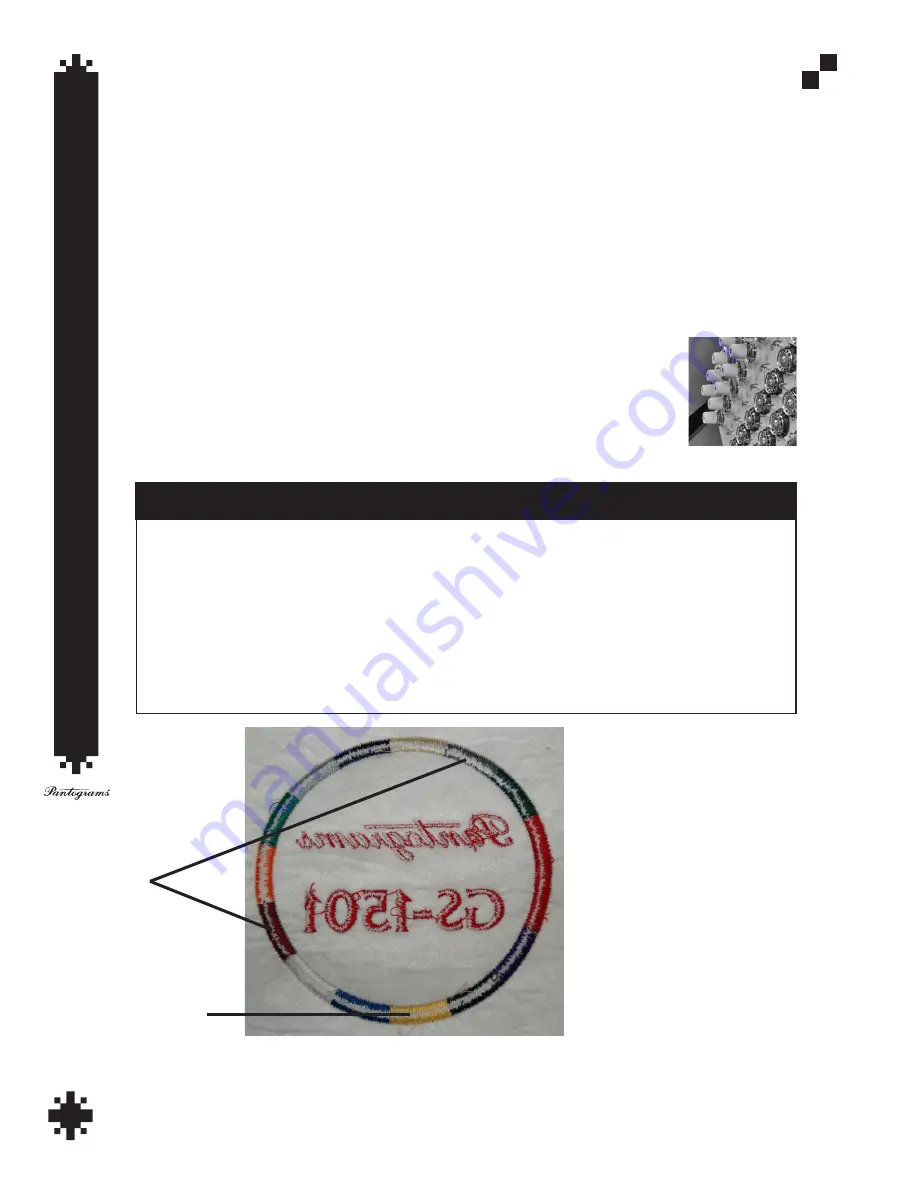

Checking Tension on

GS1501 Machines

To check for proper thread ten-

sion, perform the “GS1501.dst”

that is loaded in your embroidery

machine.

Check your bobbin case every

couple of months to see if there

is any damage to the pigtail or

tension screw. If the bobbin case

has been dropped on the floor, the

pigtail could be bent which could

affect the sew out. Also if the ten-

sion is too loose and tightening the

screw doesn’t work, then you need

to replace the bobbin case.

Note

: Improper thread path is the most common cause of sudden changes in thread tension.

Correct

Incorrect

Summary of Contents for GS1501

Page 30: ...GETTING STARTED 28 ...

Page 31: ...GETTING STARTED 29 The Control Panel Display ...

Page 62: ...EMBROIDERY BASICS 28 Notes ...

Page 64: ...MACHINE BASICS 2 ...

Page 65: ...MACHINE BASICS 3 ...

Page 70: ...MACHINE BASICS 8 ...

Page 71: ...MACHINE BASICS 9 ...

Page 78: ...MACHINE BASICS 16 Notes ...