EM

B

R

OI

D

ER

Y

B

A

S

IC

S

18

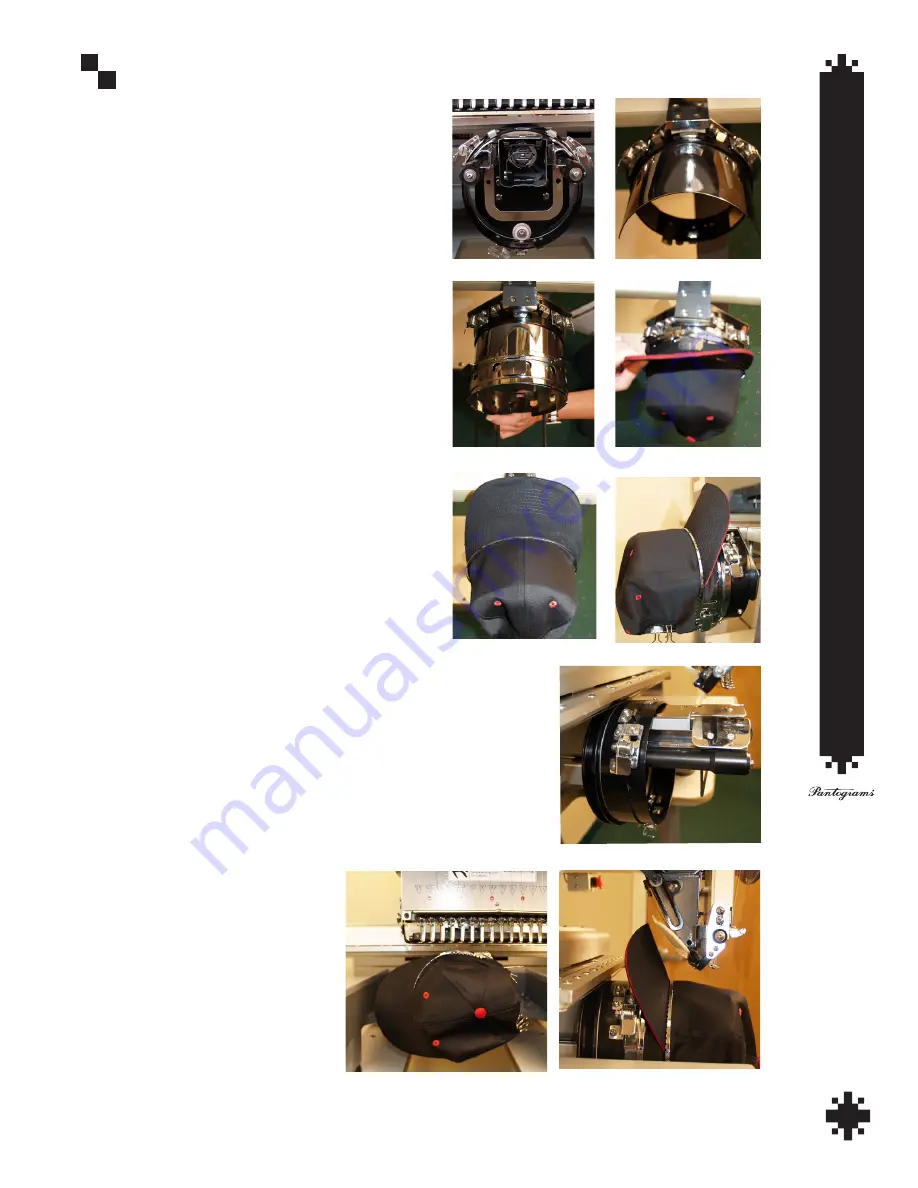

Hooping a Structured Cap

1. Attach cap driver by aligning the four rollers on

the bottom of the cap driver with the guide rail on

the underside of the arm. When aligned correct-

ly, the cap driver will slide smoothly back towards

the patograph. Line up the two Phillips screws

on the left and right. Use a Phillips screwdriver

to tighten mounting screws. (Fig. 1)

2. Turn machine on and change hoop mode to Cap.

3. Mount the cap gauge to your machine tabletop.

Attach it so that the mount is up and the thumb

screws are facing down. (Fig. 2)

4. Note that the clamps on the cap gauge and the

notches on the cap frame snap together. They

should be at the 10 oclock and 2 oclock positions

on both and also on the bottom at the 6 oclock

position. (Fig. 3)

5. Grab your cap. Un-snap the adjustable head

band in the back. Fold down the sweatband and

remove any cardboard packing. No backing

material is needed with a structured cap because

it contains buckram which makes the surface

stable for embroidering.

6. Mount the cap onto the cap frame by sliding the

sweatband under the silver block with the red

center alignment mark. (Fig. 4) Line the center

seam on the cap with this mark. The cap should

be covering the bottom two posts on the cap

frame.

7. Swing the cap frame band over the bill of the cap

with the bill sandwiched in the middle. The frame band

teeth should be placed in the seam of the cap where

the cap and bill meet. Clamp the frame base down.

(Fig. 5)

8. Gather the hat around to the back so the front is flat and

snug. Use the

bent office clamps

to attach the back of

the cap to the bottom posts of the cap frame on the left

and right. (Fig. 6)

9. Push all the snap clamps on the gauge to release the

cap.

10. Attach the cap to the ma-

chine by rotating the cap 90

degrees to clear the presser

feet. Once the presser feet

have been cleared, rotate cap

with bill facing up and snap into

the clamps on the driver. (Fig.

7,8,9)

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

Summary of Contents for GS1501

Page 30: ...GETTING STARTED 28 ...

Page 31: ...GETTING STARTED 29 The Control Panel Display ...

Page 62: ...EMBROIDERY BASICS 28 Notes ...

Page 64: ...MACHINE BASICS 2 ...

Page 65: ...MACHINE BASICS 3 ...

Page 70: ...MACHINE BASICS 8 ...

Page 71: ...MACHINE BASICS 9 ...

Page 78: ...MACHINE BASICS 16 Notes ...