M

ACH

IN

E

B

AS

IC

S

5

Common Adjustments - Thread Breaks

Always inspect needle position and determine if actual thread break has occurred. If no thread break is ap-

parent, check all the thread paths. Then do a manual trim and check the bobbin supply. If thread has broken,

follow the correct thread path and rethread the needle.

TO RESUME STITCHING AT THE APPROPRIATE SPOT IN THE DESIGN:

• Trim (Scissor Key) back up using your stop key and then start again.

PREVENTING THREAD BREAKS

• Remember to store thread properly since aged and improperly stored thread can cause thread breaks.

• Thread will become brittle due to prolonged exposure to air, light, heat and age. Replace the old thread and

store new thread in a dark, cool place.

• When re-threading the machine make sure that the thread goes through all the guides and in the proper

order.

• Make sure that the tension is correct. Loose tension causes thread to pile up and loop, and tight tension

causes pulling, puckering and thread stress.

• Too many stitches in a small area and/or heavy densities can cause thread breaks. Try deleting short

stitches or increasing the design by 5-10%.

• Do

NOT use tape to tie off thread ends, since tape leave a stick residue that causes friction and breaks.

• Check for burrs in the thread guides, needle eye, thread plate and hook.

• Make sure that the needle is pushed in all the way when cleaning needles.

• Replace bent or damaged needles.

• Excessive backing will apply greater friction to the needle and the thread.

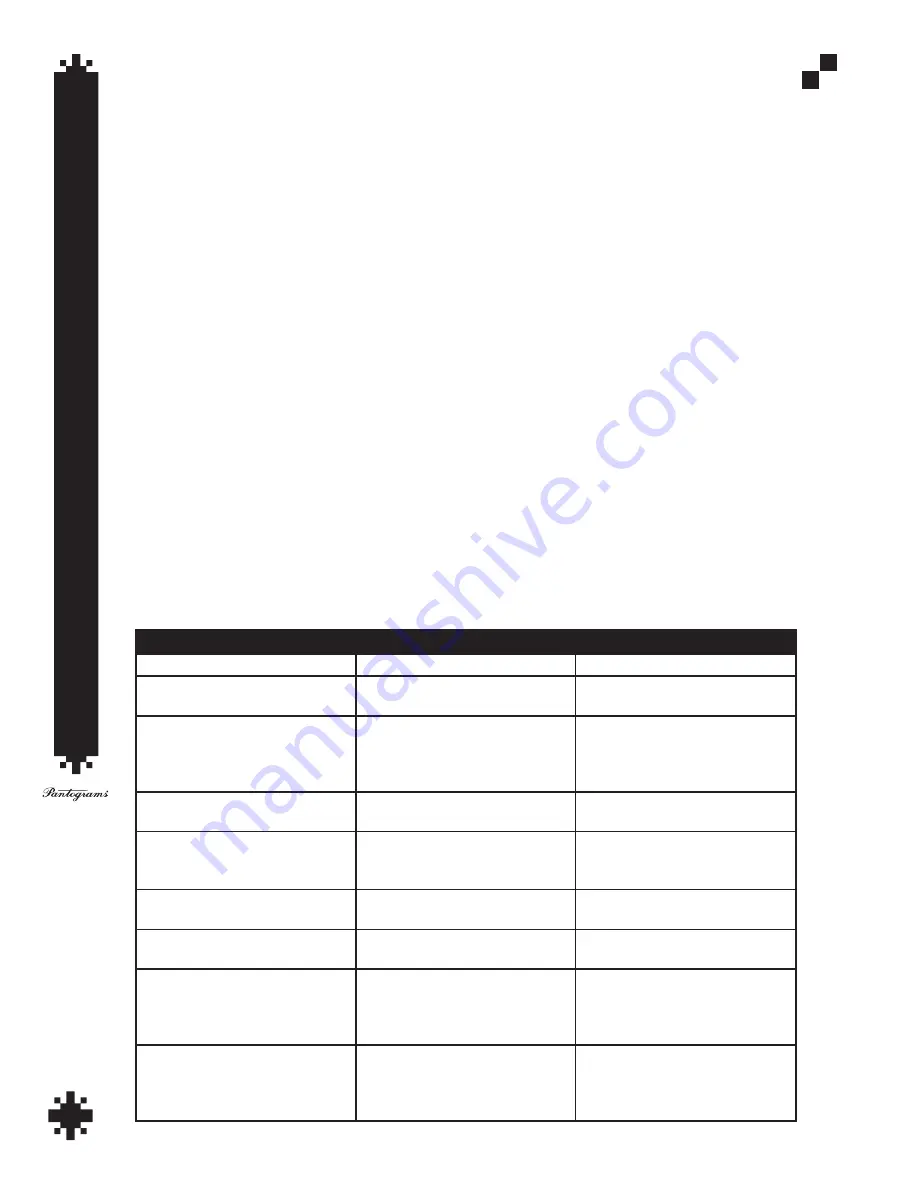

Thread Breaks

Typical Causes

Appearance

Solution

Too much or tool little tension or

poor quality thread.

A small tuft of fiber on the end of

the broken thread.

Loosen tension, change brand of

thread, try a new cone of thread

Improper placement of stitch

relative to previous stitch. Stitch

penetrates and splits previous

thread.

Broken end will have a bend in the

thread and a tuft on the end.

Edit stitch placement or re-digitize

the design.

Thread is cut by a sharp edge on

the rotary hook.

Thread will have a clean cut.

Polish or replace the rotary hook.

Hook point catches only a portion

of the thread.

Thread will fray and break.

Adjust timing of the rotary hook,

use correct needle size, try a

larger needle.

Obstruction in the thread path.

Make sure thread pulls smooth

through thread path.

Needle damage or improper

needle insertion.

Replace needle or insert needle

with scarf on the back.

Tight density

Fraying

Reduce stitch density or make

more than one pass using multiple

layers of stitching with lighter

density per layer.

Descending needle point pen-

etrating or catching thread.

Adjust take up spring so it is

working until the eye of the needle

penetrates the fabric or adjust the

tension.

Summary of Contents for GS1501

Page 30: ...GETTING STARTED 28 ...

Page 31: ...GETTING STARTED 29 The Control Panel Display ...

Page 62: ...EMBROIDERY BASICS 28 Notes ...

Page 64: ...MACHINE BASICS 2 ...

Page 65: ...MACHINE BASICS 3 ...

Page 70: ...MACHINE BASICS 8 ...

Page 71: ...MACHINE BASICS 9 ...

Page 78: ...MACHINE BASICS 16 Notes ...