Cod. 95452 – LS5T-52A

After this time interval, the oil under pressure will be overheated and the machine could be damaged.

For such extremely hard log, rotate it by

90'

to see whether it can be split in a different direction. In

any case, if you are not able to split the log, this means that its hardness exceeds the capacity of

the machine and thus that log should be discarded to protect the log splitter.

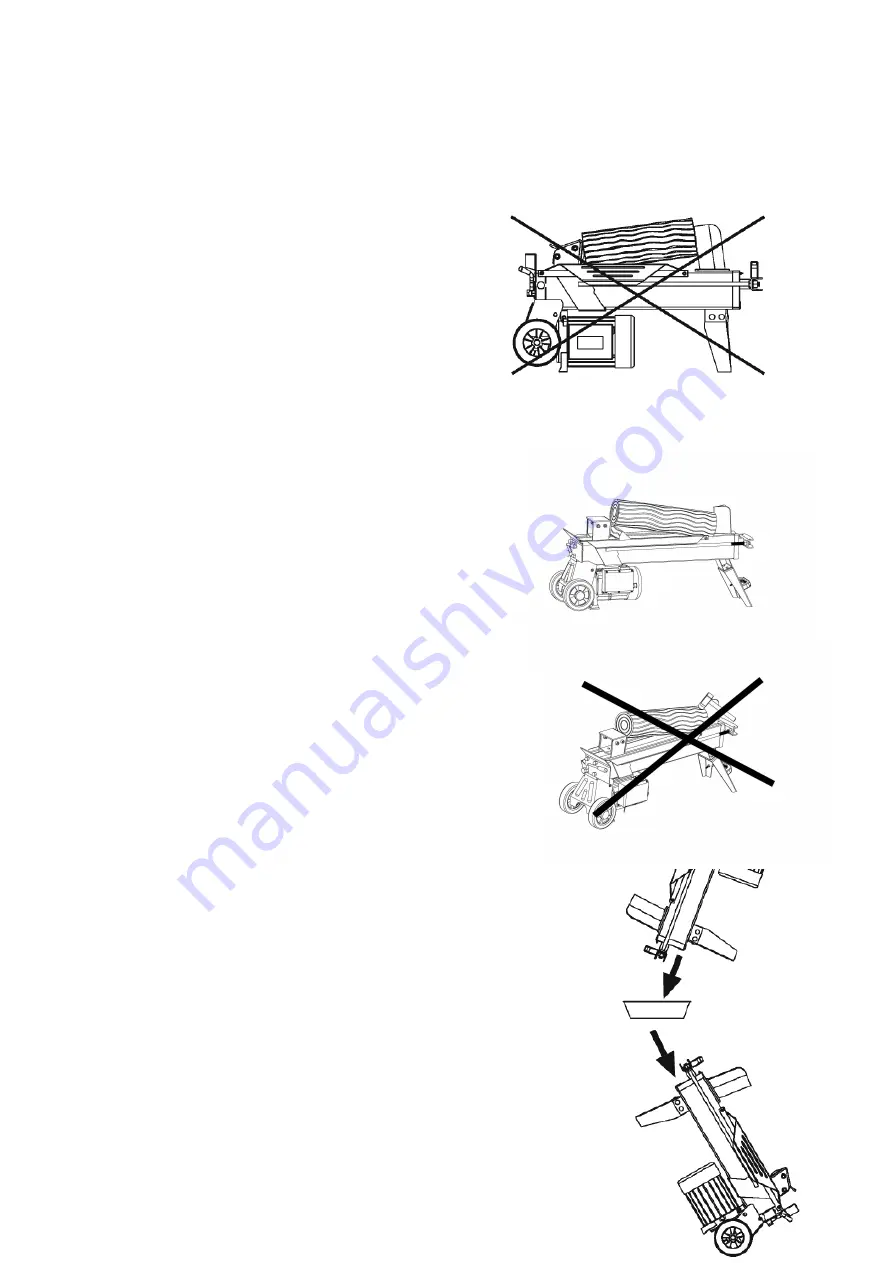

Always set logs firmly on the log retaining

plates and work table. Make sure logs will not

twist rock or slip while being split. Do not force

the blade by splitting the log on the upper part.

This will break the blade or damage the

machine.

Break log in the direction of its growing grain. Do not

place log across the log splitter for splitting. It

may be dangerous and may seriously damage the

machine.

Do not attempt to split

2

pieces of logs at the same time. One of them may fly up and hit you.

FREEING A JAMMED LOG

Release both controls.

After the log pusher moves back and

completely stops at its starting position,

insert a wedge wood under the jammed

log.

Start the log splitter to push the wedge

wood to go completely under the

jammed one.

Repeat above procedure with sharper

slope wedge woods until the log is cornpletely freed.

Do not try to knock the jammed log off.

Knocking about will damage the machine or

may launch the log and cause accident.

REPLACING HYDRAULIC OIL

Replace the Hydraulic oil in the log splitter after every 150 hours of use.

Take following steps to replace it. Make sure all moving parts stops and

the log splitter is unplugged.

Unscrew Oil Drain Bolt with Dipstick to remove it.

Turn the log splitter on the Support Leg side over an 4 liters capacity

container to drain the hydraulic oil off.

Turn the log splitter on the the motor side.

Refill fresh hydraulic oil at the volume as per the hydraulic oil capacity of

a particular model indicated in above specifications table.

Summary of Contents for 95452

Page 17: ...Cod 95452 LS5T 52A ...