9

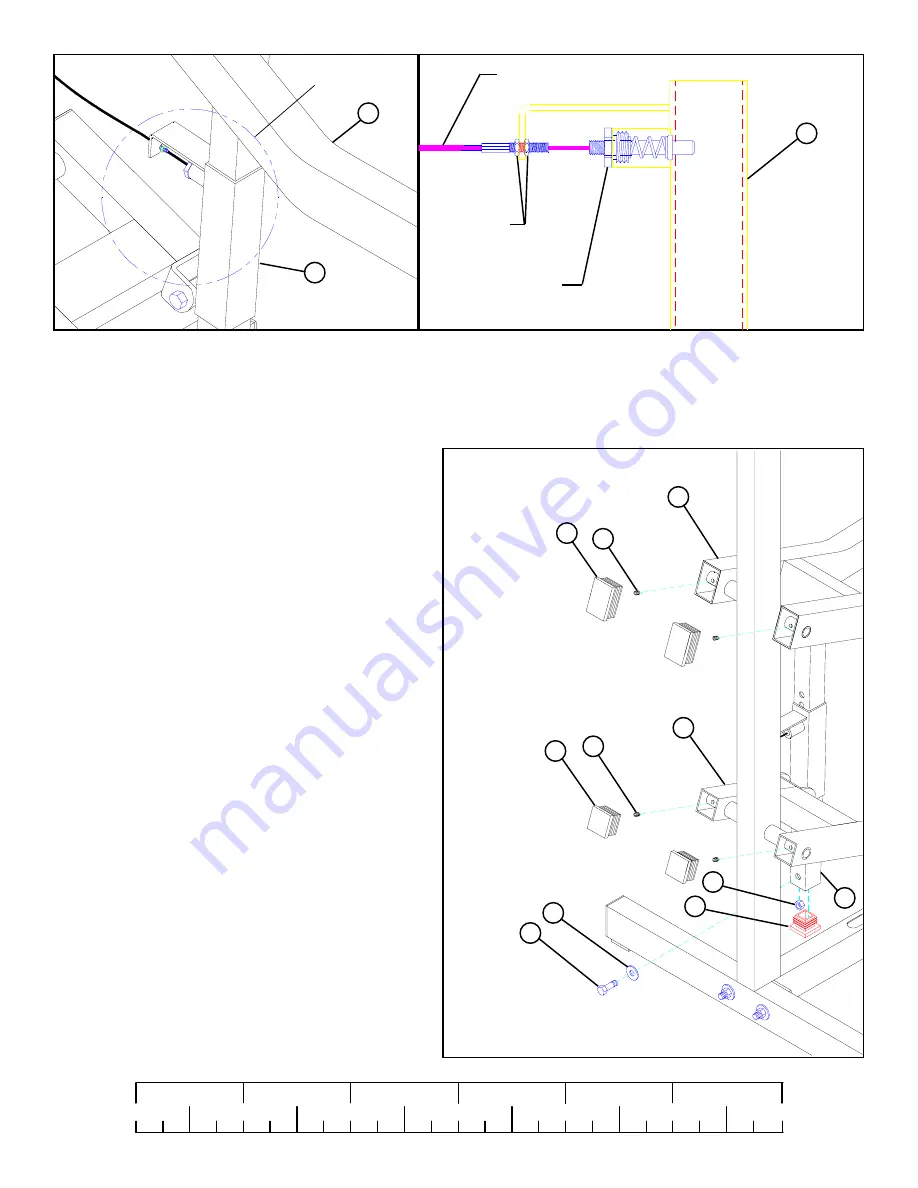

FIGURE 9

0

1

2

3

4

5

6

1/2

1/2

1/2

1/2

1/2

1/2

FIGURE 10

DETAIL 9

DETAIL 9

1/4” NUTS

PUSH/PULL

CABLE

SPRING PIN

ASSEMBLY

13

DO NOT OVERTIGHTEN!

Assemble the PUSH/PULL CABLE from the PRESS ARM (8) to the SPRING PIN HOUSING and to the L-BRACKET on the

RECEIVING TUBE (13) as shown on FIGURE 9 and DETAIL 9 using the following steps:

STEP 9

·

Thread the first 1/4-28 IN. NUT to the bottom of the threaded end of the CABLE. Allow the other 1/4-28 IN. NUT to hang loose

on the exposed CABLE until the SPRING PIN ASSEMBLY is attached.

·

Securely assemble the SPRING PIN ASSEMBLY to the

SPRING PIN BARREL. (!!! IMPORTANT !!! TIGHTEN

THE NUT OF THE SPRING PIN ASSEMBLY SE-

CURELY)

·

Swing the PRESS ARM (8) up until the SPRING PIN of the

PUSH/PULL CABLE engages in one of the adjustment

holes.

·

Thread the second 1/4-28 IN. NUT onto the threaded end of

the CABLE, and cinch the two 1/4-28 IN. NUTS around the

flat.

·

Use the extra thread on the end of the CABLE to adjust out

slack.

( !!! DO NOT ADJUST OUT TO FAR !!! AL-

WAYS ALLOW SPRING PIN ASSEMBLY TO FULLY

ENGAGE

)

STEP 10

• Securely tighten two 5/32” SET SCREWS (65) and insert

two 3 X 2” END CAPS (75) into the open ends of PRESS

ARM (8) as shown in FIGURE 10.

• Securely tighten two 5/32" SET SCREWS (65) and insert

two 2” SQ. END CAPS (76) into the open ends of PRESS

ARM LEVER (9) as shown in FIGURE 10.

• Securely tighten one 3/8 X 1” BOLT (35), one 3/8” WASHER

(51), and one 3/8” LOCKNUT (48) to the bottom of AD-

JUSTMENT SLIDE (6) as shown in FIGURE 10.

• Insert one 1-3/4” SQ. END CAP (77) into the end of AD-

JUSTMENT SLIDE (6) as shown in FIGURE 10.

48

76

51

65

75

65

6

77

9

8

3/8 X 1” 35

8

13