14

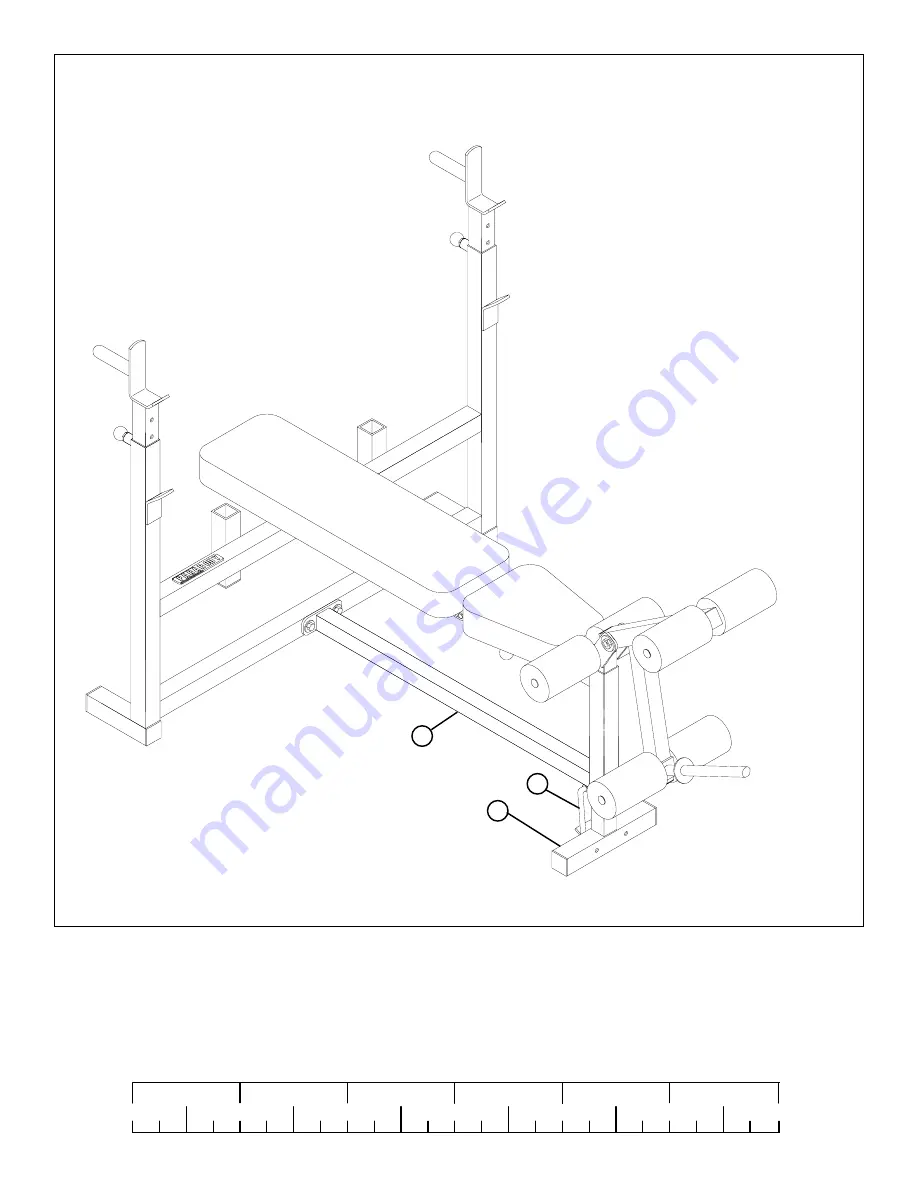

FIGURE 9

STEP 9:

2

• When ready to perform LEG CURLS or LEG EXTENSION, pull up slowly on the front of the BENCH FRAME (2) and allow the

U-PIN (10) to rest on top of the TAB of the BASE LEG (5).

(NOTE: THE BENCH FRAME MUST BE ADJUSTED UP

WHEN USING THE LEG EXTENSION TO ALLOW PROPER CLEARANCE FOR WEIGHT PLATES)

5

0

1

2

3

4

5

6

1/2

1/2

1/2

1/2

1/2

1/2

10