15

Important Safety Instructions

1. Read and follow all warning notices and instructions marked on the product or

included in the manual.

2. All installation and service must be performed by qualified service personnel, as

opening or removing covers may expose dangerous voltage points or other risks.

3. This product is intended to be used with a 3-wire grounding type plug – a plug

which has a grounding pin. This is a safety feature. Equipment grounding is vital to

ensure safe operation. Do not defeat the purpose of the grounding type plug by

modifying the plug or using an adapter.

Prior to installation, use an outlet tester or a voltmeter to check the AC receptacle

for the presence of earth ground. If the receptacle is not properly grounded, the

installation must not continue until a qualified electrician has corrected the problem.

If a 3-wire grounding type power source is not available, consult a qualified

electrician to determine another method of grounding the equipment.

4. Slots and openings in the cabinet are provided for ventilation. To ensure reliable

operation of the product and to protect it from overheating, these slots and

openings must not be blocked or covered.

5. Do not allow anything to rest on the power cord and do not locate the product where

persons will walk on the power cord.

6. Disconnect power before servicing.

7. General purpose cables are provided with this product. A UL Listed/CSA Certified,

minimum No. 26 AWG, telecommunications cable is provided for connection to the

network. Use this cable to reduce the risk of fire.

Special cables, which may be required by the regulatory inspection authority for the

installation site, are the responsibility of the customer.

8. When installed in the final configuration, the product must comply with the

applicable Safety Standards and regulatory requirements of the country in which it

is installed. If necessary, consult with the appropriate regulatory agencies and

inspection authorities to ensure compliance.

9. A rare phenomenon can create a voltage potential between the earth grounds of

two or more buildings. If products installed in separate buildings are

interconnected, the voltage potential may cause a hazardous condition. Consult a

qualified electrical consultant to determine whether or not this phenomenon exists

and, if necessary, implement corrective action prior to interconnecting the products.

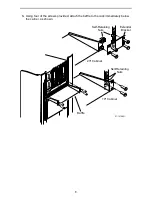

10. Filler panels are provided with the access carrier to cover unused slots. You

must

install filler panels on the unused slots to avoid possible injury from electrical shock

and to maintain compliance with FCC rules.

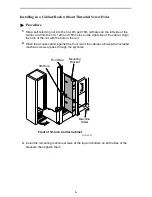

11. This access carrier must be installed in a complete enclosure such as a cabinet or

enclosed rack to prevent user access to hazardous circuits.

!