(800) 471-8769

12

Copyright 2021 © Paragon Tank Truck Equipment

Oil Capacity

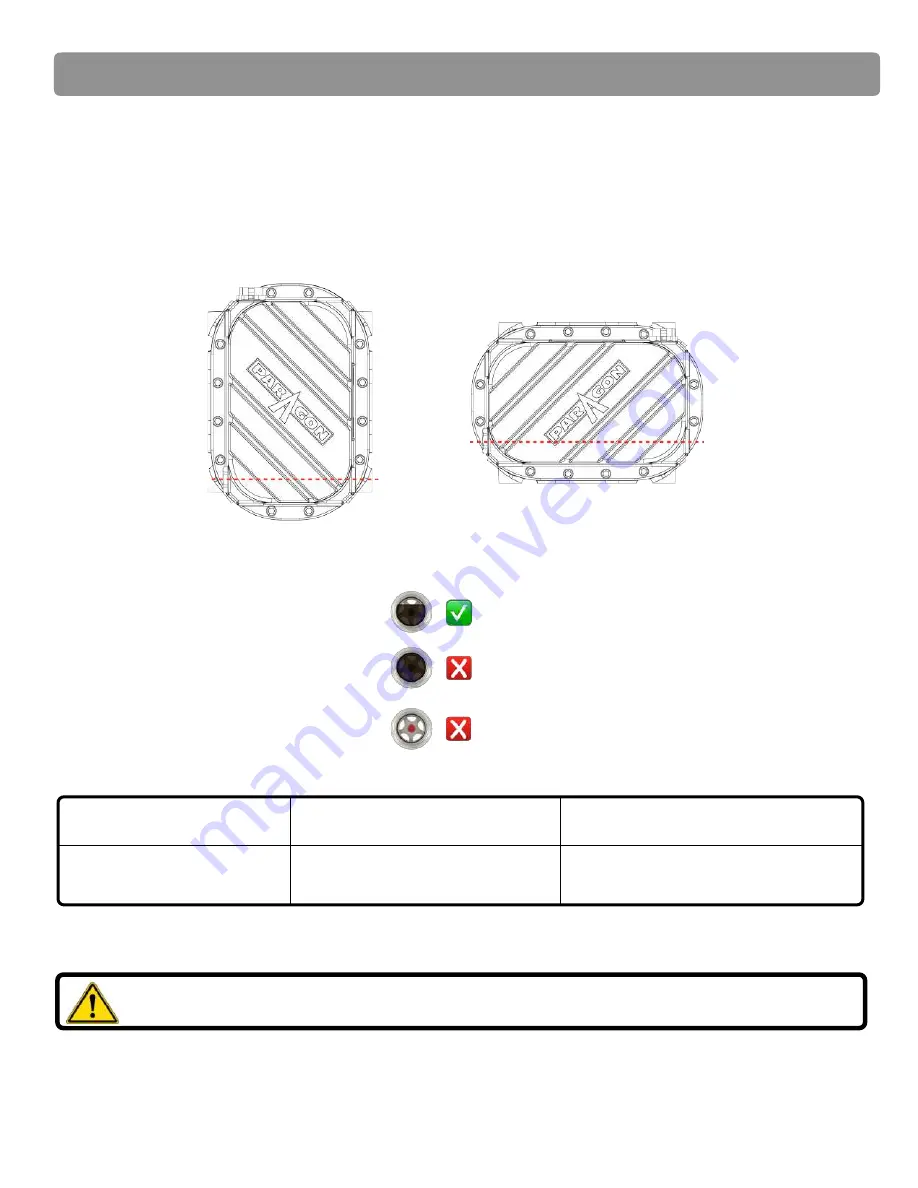

Horizontal Air Flow (Standard Mount)

Vertical Air Flow

Drive End (Front Cover)

Non-Drive End (Rear Cover)

15 oz (0.5 qt.)

25 oz (0.8 qt.)

28 oz. (0.9 qt.)

48 oz. (1.5 qt.)

Max Oil

Fill Level

Max Oil

Fill Level

(Fig. 6)

Lubrication Instructions

• Use Paragon Lobe Blower Oil (part number: 409-007).

Caution

Mixing or incorrect oil can result in gear and bearing failure.

Note:

Front oil tank will fill slower than the rear tank. Allow oil to settle after it begins to show in the sight glass.

Correct Level

Over filled

Under Filled

Sight Glass

Filling

Instructions