23

If this machine is to be installed in a

public use facility, ASTM F1749

requirements specify that the facility

sign shown to the right is to be

installed in plain view.

If you did not receive the facility sign

with your order, you can obtain one

free of charge from Paramount by

calling 1-800-721-2121.

BE ALERT!

THE FITNESS EQUIPMENT IN THIS FACILITY

PRESENTS HAZARDS WHICH, IF NOT AVOIDED,

COULD CAUSE SERIOUS INJURY OR DEATH.

PRIOR TO USING THE EQUIPMENT, READ THE WARNING LABELS

AND INSTRUCTION PLACARDS AFFIXED TO EACH MACHINE.

IF YOU ARE UNSURE ON HOW TO USE A MACHINE, SEEK THE

ASSISTANCE OF OUR FLOOR PERSONNEL. WE WILL BE HAPPY

TO INSTRUCT YOU ON HOW TO USE THE EQUIPMENT PROPERLY.

IMMEDIATELY REPORT ANY PIECE OF EQUIPMENT THAT IS NOT

FUNCTIONING PROPERLY TO OUR FLOOR PERSONNEL SO THAT

IT MAY BE EVALUATED AND SERVICED PROMPTLY.

DO NOT ATTEMPT TO USE OR FIX ANY PIECE OF EQUIPMENT

THAT IS NOT FUNCTIONING PROPERLY

ASTM F1749-96

LBL--WSEM-01065

B2065

LBL-PR-FS100RR

(contains LB. & KG.)

LBL-WRN-XFT300

B2141C

LBL-WRN-0012

B 2051

LBL-WRN-0006

LBL-PR-FS100RL

LBL-PR-FS100LR

LBL-PR-FS100LL

M

ACHINE

L

ABELS

The following are the Warning labels required for this FS-100. If any of these labels are missing or

become damaged contact Paramount. Note: these labels are not to scale.

Summary of Contents for FS-100

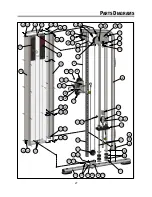

Page 27: ...27 PARTS DIAGRAMS...

Page 29: ...29 PARTS DIAGRAMS...

Page 34: ...NOTES...

Page 35: ......