RUBBER

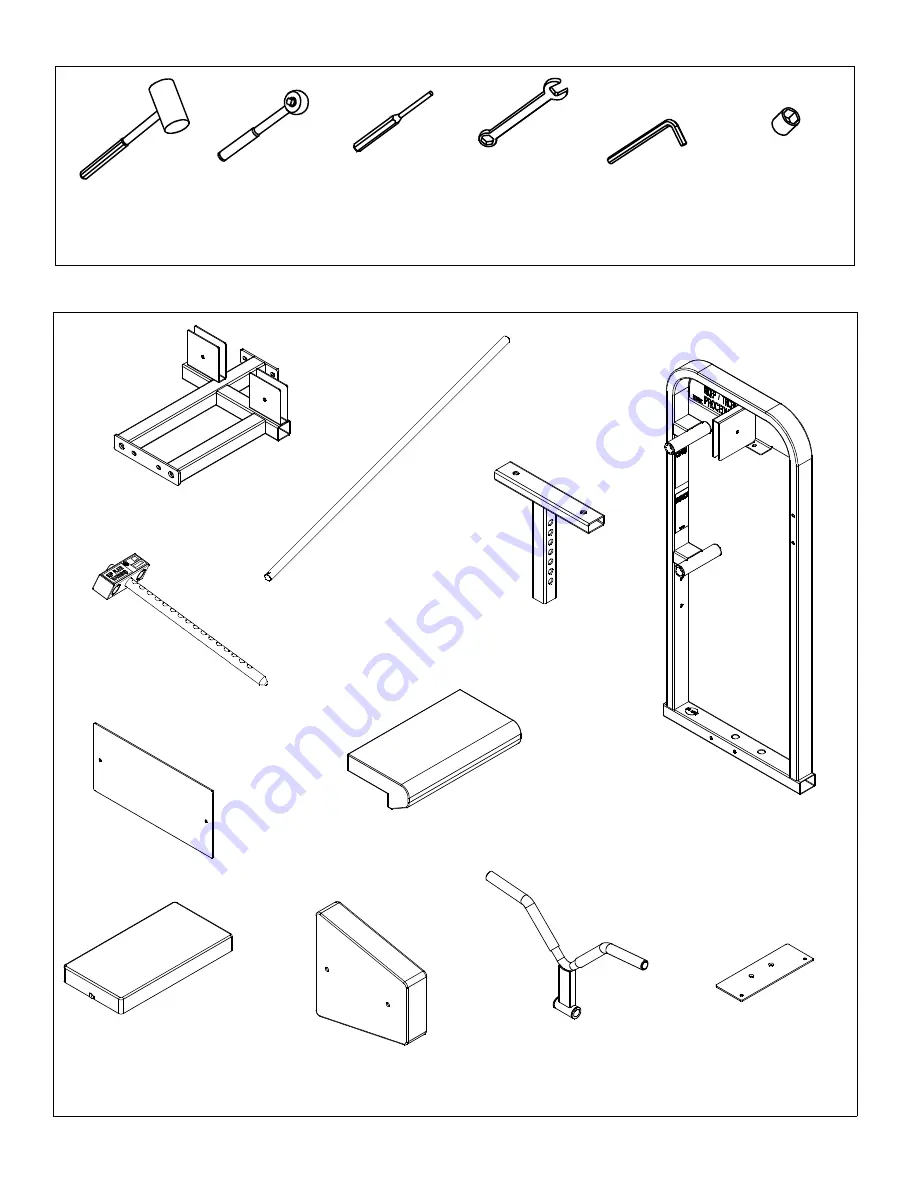

SOCKET

9/16” (14mm)

3/4” (19mm)

SOCKET

WRENCH

7/16” (11mm)

9/16” (14mm)

3/4” (19mm)

7/16” (11mm)

ALLEN WRENCH

15/16” (24mm)

PUNCH

5/32” (4mm)

3/16” (5mm)

7/16” (11mm)

MALLET

WRENCH

7/8” (22mm)

TOOLS REQUIRED:

3

9099780X

9000801X (2)

1701510X

1701591

1701565X

0101520X

0101599

8001520X

1701515

8001525

1701570X

SF-1700CTN1: