46. Before spreading sand over floor unscrew

pressure plates and fill base channel and

pressure plate areas with sand to prevent

any movement.

Re-install pressure plates

Note:

It is very important that this step is

completed correctly. The sand has to be

packed tightly to eliminate movement of

pressure plate when walked upon.

48. Spread the sand over the entire floor area

to an even depth of approximately 50mm

making sure you have 50mm of sand over

the pressure plate.

49. Compact the sand on the floor by

tramping or rolling until a footprint no

longer shows.

50. Installation of liner

Remove all seats and connector plates.

51. Place the pool pad (GROUND COVER)

over the entire floor area and hold it in

position by taping in to the pool wall.

53. Position the liner so that wall-floor

seam is an equal distance from pool

wall at both ends and sides. The liner

has several seams running across the

pool floor, which must be straight and

parallel to side frames.

52. Unroll the liner in the center of the pool

with the smooth weld up. (The liner is

easier to install if left unrolled in the sun

to warm and soften) .

54. Pull the liner wall up over the pool wall

and hold in place with plastic coping strips. (7)

Note:

Remove footwear before walking

on liner.

LIDO POOL

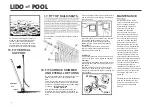

12. PREPARE COVE

AND SPREAD

SAND ON BASE

13. INSTALL GROUND

COVER

14. INSTALL LINER

15. CHECK & SECURE

LINER

47. Build up an even cove of firm sand or

earth around the wall of the pool

approximately 150mm and pack firmly.

Summary of Contents for Poolquip Lido

Page 1: ...LIDO INGROUND OR INDECK POOLS OVAL POOL INSTRUCTION MANUAL ...

Page 2: ...LIDO POOL A few important safety hints Enjoy Your Swimming Safely ...

Page 10: ...LIDO POOL ASSEMBLE FRAMES FOR POOLS ...

Page 19: ...Takapuna 11 Barrys Point Rd Takapuna Auckland 0622 Email northshore paramountpools co nz www ...