English

3 / 12

ATT025-040

Y

It is recommended to complete this type of starting with the air out-

let valve closed, to preserve the correct operation of the desiccant bed.

4.3 Operation

Leave the dryer in working during the period of working of the air com-

pressor.

• The dryer works automatically, calibrations are not required on the

fi eld;

• if there are excessive and unexpected air fl ows, by-pass to avoid

overloading the dryer.

4.4 Operation with Dew point control

In the case of work loads below the nominal or if you want different dew

point of -40 ° C, it is possible to work in

Dew Point Control

. The system

automatically controls the time of the cycles of operation to obtain and

maintain the predetermined dew point, with the result of energy saving in

case of work with partial loads.

Procedure to set “dew point control”.

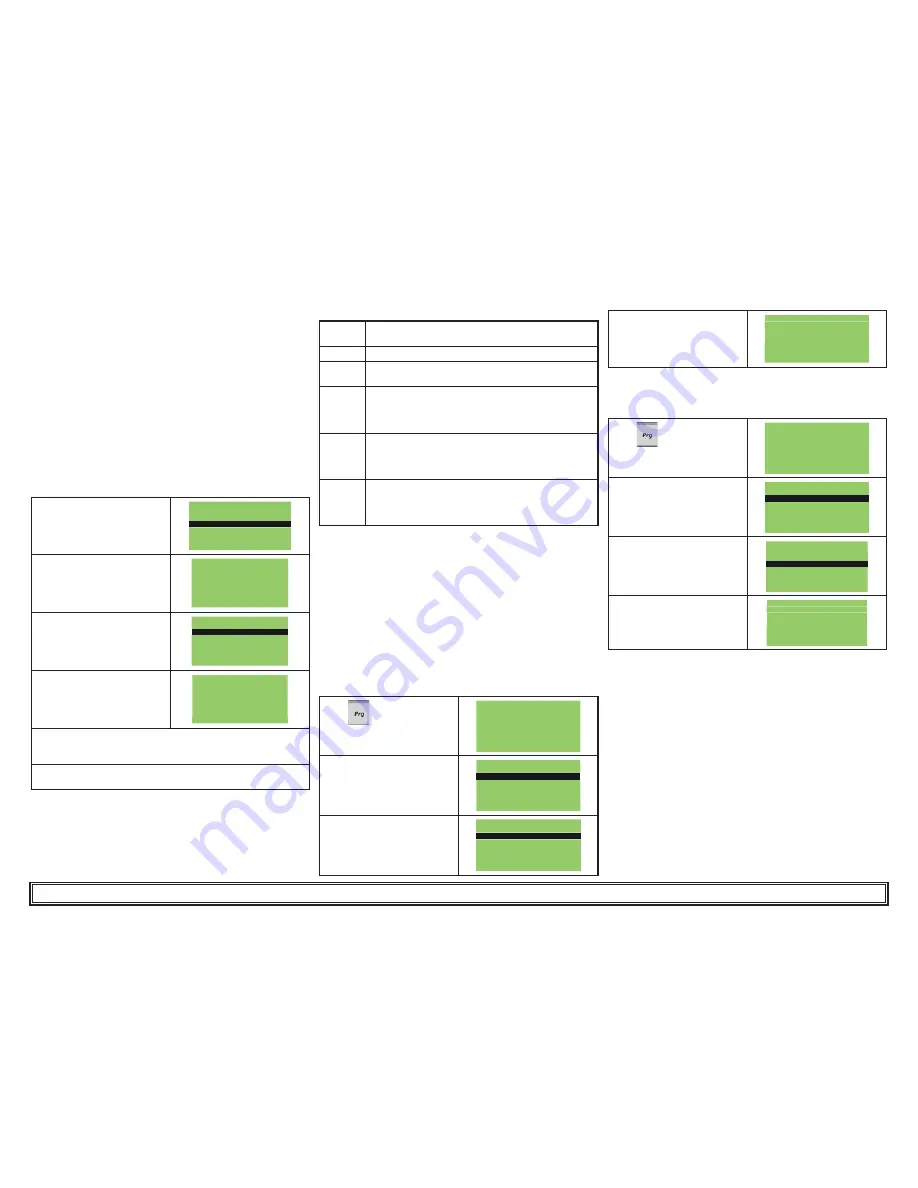

Press Prg to enter on main menu

Using

Up

and

Down

select

“

USER SETTINGS”

Press

Enter

to confi rm.

- - -Main Menu - - -

START/STOP

USER SETTINGS

SERVICE

INFORMATION

Shows the “User settings menu

- User Settings Menu -

DRYER SETTINGS

DATE/TIME

BMS

MOISTURE DRAIN

OTHER

LANGUAGE

Using

Up

and

Down

select

“DRYER SETTINGS”

Press

Enter

to confi rm.

- User Settings Menu -

DRYER SETTINGS

DATE/TIME

BMS

MOISTURE DRAIN

OTHER

LANGUAGE

Using

Up

and

Down

select

the parameter.

Press

Enter

to confi rm.

U1 - DEWP.SET (°C): -40

U2 - PRESSURE (barg): 07

U3 - MODE: Forced Rig.

U4 - ALARM RELAY MODE:

by: ALARMS & WARNINGS

U6 - DPM: NO FITTED

Select the parameter

U1- DEWP.SET

(°C) and set the value you need.

Press

Enter

to confi rm. see Table 1 for identifying the correct value

to be set

Select the parameter

U6- DPM

: set the mode

FITTED.

Press

Enter

to confi rm.

Table 1

Dew

Point

Application

-70°C

Request for a very low dew point.

-40°C

Request for a very low dew point.

(depend on the type of the process.).

-20°C

Request for a low dew point.

When the pipes air compressed are in external environ-

ment and the minimum winter ambient temperatures are

above -10 to -15 ° C.

-10°C

Request for a low dew point.

When the pipes air compressed are in external environ-

ment and the minimum winter ambient temperatures are

above -5°C.

0°C

Request for a dew point standard.

When the pipes air compressed are in external environ-

ment and the minimum winter ambient temperatures are

above 10°C.

Important: for correct readings, the Dew point sensor must work at

a precise air fl ow, which is adjusted by a fl ow meter (no. 33).

CORRECT CALIBRATION: LEVEL 2 ÷ 5 liters/minutes

To ensure optimal Dew point sensor operation, comply with the

maintenance instructions given in para. 6.4.

In this regard, the sensor connection is fi tted with a shut-off valve to

facilitate maintenance

4.5 Stop

It is possible to stop the dryer in two different mode:

• NORMAL

• FORCED

Y

Is recommended to use the option “Normal”.

Y

Use the option “Forced” only if necessary.

Mode stop “NORMAL”:

Press

to enter on “Main Menu”

- - -Main Menu - - -

START/STOP

USER SETTINGS

SERVICE

INFORMATION

Select

START/STOP

press

Enter

to confi rm

- - -Main Menu - - -

START/STOP

USER SETTINGS

SERVICE

INFORMATION

Select

NORMAL START/STOP

press

Enter

to confi rm

- On/Off Menu -

NORMAL START/STOP

STOP DIRECTLY

Press

Enter

to confi rm the

STOP

ENABLE UNIT RUNNING

STOP

Y

IMPORTANT: wait for the dryer to perform the complete cycle

of regeneration, IT IS ABSOLUTELY PROHIBITED TO STOP THE

FLOW OF AIR UNTIL THE STOP OF THE DRYER.

Mode stop “FORCED”.

Press

to enter on “Main Menu”

- - -Main Menu - - -

START/STOP

USER SETTINGS

SERVICE

INFORMATION

Select

START/STOP

press

Enter

to confi rm

- - -Main Menu - - -

START/STOP

USER SETTINGS

SERVICE

INFORMATION

Select

“Stop Directly”

Press

Enter

to confi rm

- On/Off Menu -

NORMAL START/STOP

STOP DIRECTLY

Select

YES

and confi rm.

After few second the value return

to “

NO”

.

FORCING SYSTEM OFF

NO

Y

IMPORTANT:

Machine ON: the machine should always work under pressure.

Machine OFF: do not allow air to fl ow into the tanks with the dessi-

cant when the machine is turned off.