English

7 / 14

ATT140-340

6 Maintenance

a) The machine is designed and built to guarantee continuous opera-

tion; however, the life of its components depends on the maintenance

performed.

b)

Z

When requesting assistance or spare parts, identify the ma-

chine (model and serial number) by reading the data plate located on the

unit.

c) Circuits containing 3 kg or more of refrigerant fl uid are checked to

identify leaks at least once a year.

Circuits containing 30 kg or more of refrigerant fl uid are checked to iden-

tify leaks at least once every six months. ((EU) No. 517/2014 art. 4.3.a,

4.3.b).

d) For machines containing 3 kg or more of refrigerant fl uid, the opera-

tor must keep a record stating the quantity and type of refrigerant used,

an quantities added and that recovered during maintenance operations,

repairs and fi nal disposal ((EU) No. 517/2014 art. 6). An example of this

record sheet can be downloaded from the site: www.dh-hiross.com.An

example of this record sheet can be downloaded from the site: www.dh-

hiross.com.

6.1 General instructions

!

Before any maintenance, make sure:

• the pneumatic circuit is no longer pressurized;

• the dryer is no longer powered.

Always use the Manufacturer’s original spare parts: otherwise the Manu-

facturer is relieved of all liability regarding machine malfunctioning

Z

In case of refrigerant leakage, contact qualifi ed and authorized per-

sonnel.

Y

The Schrader valve must only be used in case of machine malfunc-

tion: otherwise any damage caused by incorrect refrigerant charging will

not be covered by the warranty.

6.2 Refrigerant

Y

Charging: any damage caused by incorrect refrigerant replacement

carried out by unauthorized personnel will not be covered by the war-

ranty.

Y

The equipment contains fl uorinated greenhouse gases.

At normal temperature and pressure, the R407c refrigerant is a colour-

less gas classifi ed in SAFETY GROUP A1 - EN378 (group 2 fl uid accord-

ing to Directive PED 2014/68/EU);

GWP (Global Warming Potential) = 1774.

!

In case of refrigerant leakage, ventilate the room.

6.3 Desiccant agent

The desiccant agent used is not harmful; during the fi lling and emptying

of the tanks, observe the following warnings:

a) wear a dust mask and protective goggles

b) If the material is accidentally dispersed to the ground, immediately

clean

!

Risk of slipping.

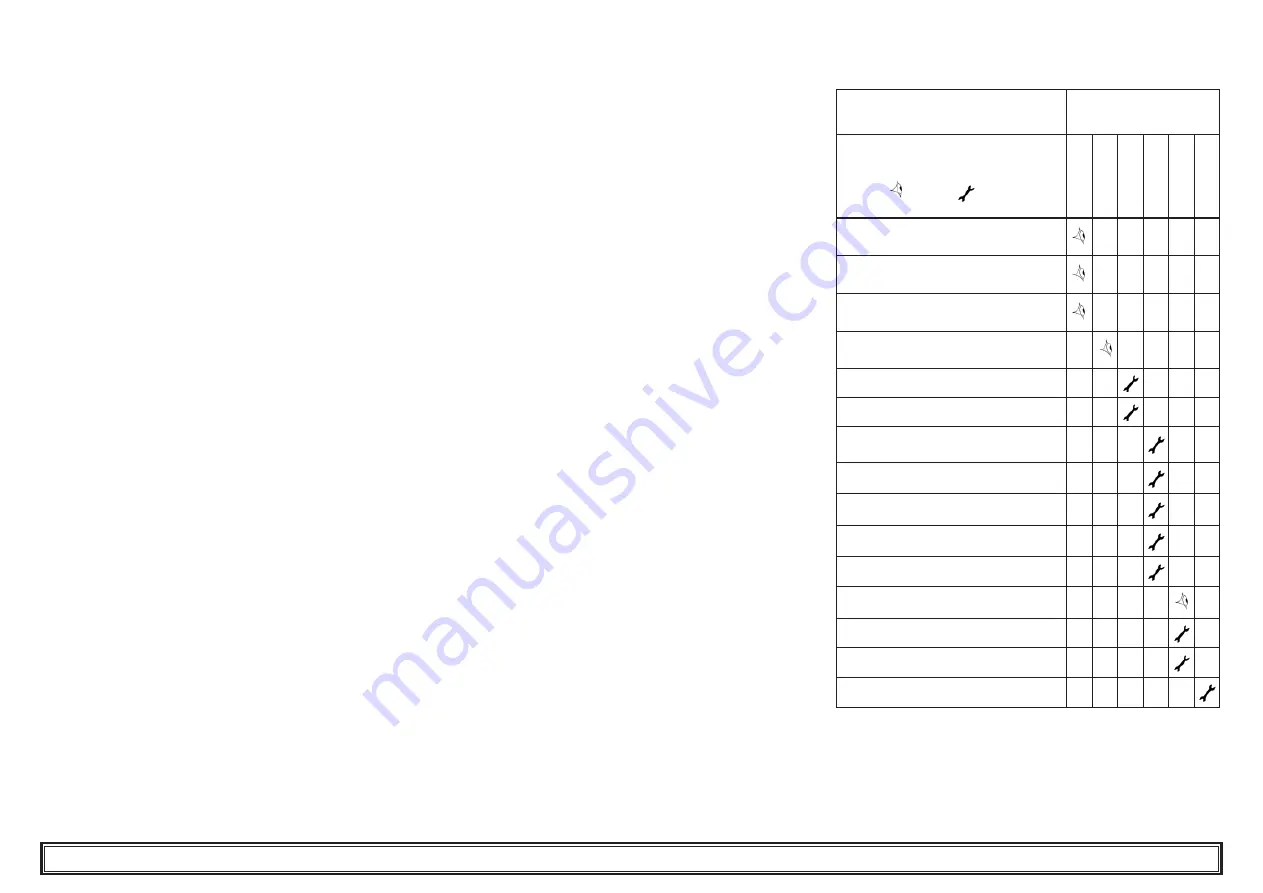

6.4 Preventive Maintenance Programme

To guarantee lasting maximum dryer effi ciency and reliability:

Maintenance

Activity description

Maintenance Interval

(standard operating

conditions)

Activity

Control

Service

Daily

W

eekly

4 Months

12 Months

24 Months

48 Months

Check the POWER ON indicator is lit.

Check control panel indicators

Check the correct level of the fl ow meter.

Check condensate drain.

Clean condenser fi ns.

Check electrical absorption

Depressurize the unit.

Complete drain maintenance

Depressurize the unit.

Substitute pre- and post-fi lter elements.

Substitute fi lter element, oil separator fi l-

ter and dust preventer fi lter.**

It is recommended to replace the pres-

sure dew point sensor.

Main solenoids- change

Check the silencer yearly and when

change the desiccant agent

No return Valve- change

Solenoids Drain- change

Desiccant agent

**

Y

Refer to the manufacture date of the machine, written in the

data label.

Maintenance work must be performed by authorized personnel.

All spare parts and their respective codes can be found listed on

section 9.4.

Summary of Contents for ATT140

Page 2: ......

Page 16: ...Italiano 14 14 ATT140 340...

Page 30: ...English 14 14 ATT140 340...

Page 44: ...Espa ol 14 14 ATT140 340...

Page 58: ...Deutsch 14 14 ATT140 340...

Page 59: ......