English

2/8

ICE150-230

2 Introduction

These water coolers are monoblock units for the production of cooled

water in a closed circuit.

The fan, pump and compressor motors are equipped with a thermal

protector that protects them against possible overheating.

2.1 Transport

The packed unit must remain:

a) Upright;

b) Protected against atmospheric agents;

c) Protected against impacts.

2.2 Handling

Use a fork-lift truck suitable for the weight to be lifted, avoiding any

type of impact (see paragraph 7.2).

2.3 Inspection

a) All the units are assembled, wired, charged with refrigerant and oil

and tested in the factory;

b) On receiving the machine check its condition: immediately notify

the transport company in case of any damage;

c) Unpack the unit as close as possible to the place of installation.

2.4 Storage

a) Keep the unit packed in a clean place protected from damp and

bad weather.

b) Do not stack the units;

c) Follow the instructions given on the package.

3 Installation

Y

For correct installation, follow the instructions given in par.7.2, 7.3,

7.4, 7.5 and 7.9.

Y

For the correct application of the warranty terms, follow the in-

structions given in the start-up report, fi ll it in and send it back to Seller

!

Liquids to be chilled

The liquids to be chilled must be compatible with the materials used.

Examples of liquids used are water or mixtures of

water and ethylene

or propylene glycols.

The liquids to be chilled must not be fl ammable.

If the liquids to be chilled contain hazardous substances (e.g. ethylene/

propylene glycol), any liquid discharged from a leakage area must be

collected, because it is harmful to the environment. When draining

the hydraulic circuit, comply with the current regulations and do not

disperse the contents in the environment.

3.1 Operating space

To allow an unrestricted air fl ow around the chiller and easy access for

servicing, ensure the area around the unit is kept free of obstacles (see

paragraph 7.3).

Leave a space of at least 2 metres above the refrigerator in models with

vertical emission of condensation air.

3.2 Versions

Air-cooled version

Axial fans (A)

Do not create cooling air recirculation situations.

Do not obstruct the ventilation grilles.

The ducting of extracted air is not recommended for versions with axial

fans.

Centrifugal version (C)

Always ensure a minimum counterpressure on the delivery of

fans, ducting the individual hot air outlets.

Water- cooled version (W)

If the water to the condenser is in open circuit, install a mesh fi lter on

the condensation water inlet.

Please note that for special cooling water types such as demineral-

ized, deionized or distilled it is necessary to contact the manufacturer

to verify which kind of condenser should be used since the standard

material may not be suitable.

3.3 Water circuit

3.3.1

Checks and connection

Y

Before connecting the chiller and fi lling the water circuit, check

that all the pipes are clean. If not, wash them out thoroughly.

Y

If the plumbing circuit is of the closed type, under pressure it is

advisable to install a safety valve set to 6 bar.

Y

Always install mesh fi lters on the water inlet and outlet pipelines.

Y

If the hydraulic circuit is intercepted by automatic valves, protect

the pump with an anti-hammering system.

Y

If the hydraulic circuit is emptied for shut-down periods we

recommend that you add lubricating fl uid to the pump’s impeller to

avoid the risk of blockage when it is re-started. In case the impeller is

blocked then you should unblock it manually.

Remove the rear cover of the pump and carefully turn the plastic fan.

If the impeller is stuck then remove the fan and turn the impeller shaft

directly. After un-blocking the impeller re-assemble the fan and cover.

Preliminary checks

1) Check that any shut-off valves in the water circuit are open.

2) In the case of a closed water circuit, check that an expansion tank

of suitable capacity has been installed. See paragraph 3.3.3.

Connection

1) Connect the water cooler to the inlet and outlet piping, using the

special connections located on the back of the unit.

We recommend the use of fl exible unions to reduce system rigidity.

2) Fill the water circuit using the fi tting provided on the rear of the

chiller (

).

3) The tank is equipped with a breather valve that should be operated

manually when fi lling the tank. Also, if the hydraulic circuit has high

points, install a vent valve at the highest points.

4) We recommend that taps are installed on the inlet and outlet pipes,

so that the unit can be excluded for maintenance when necessary.

5) If the chiller works with an open tank, the pump must be installed

on intake to the tank and on delivery to the chiller.

Subsequent checks

1) Check that the tank and the circuit are completely full of water and

that all the air has been expelled from the system.

2) The water circuit must always be kept full. For this reason, carry

out periodic checks and top the circuit up if necessary, or install an

automatic fi lling kit.

3.3.2

Water and ethylene glycol

If installed outdoors or in an unheated indoor area, it is possible that

the water in the circuit may freeze if the system is not in operation dur-

ing the coldest times of the year.

To avoid this hazard:

a) Equip the chiller with suitable antifreeze protection devices, avail-

able from the manufacturer as optional accessories;

b) Drain the system via the drain valve if the chiller is to remain idle for

a prolonged period;

c) Add an appropriate quantity of antifreeze to the water in circulation

(see table).

Sometimes the temperature of the outlet water is so low as to require

the addition of ethylene glycol in the following percentages.

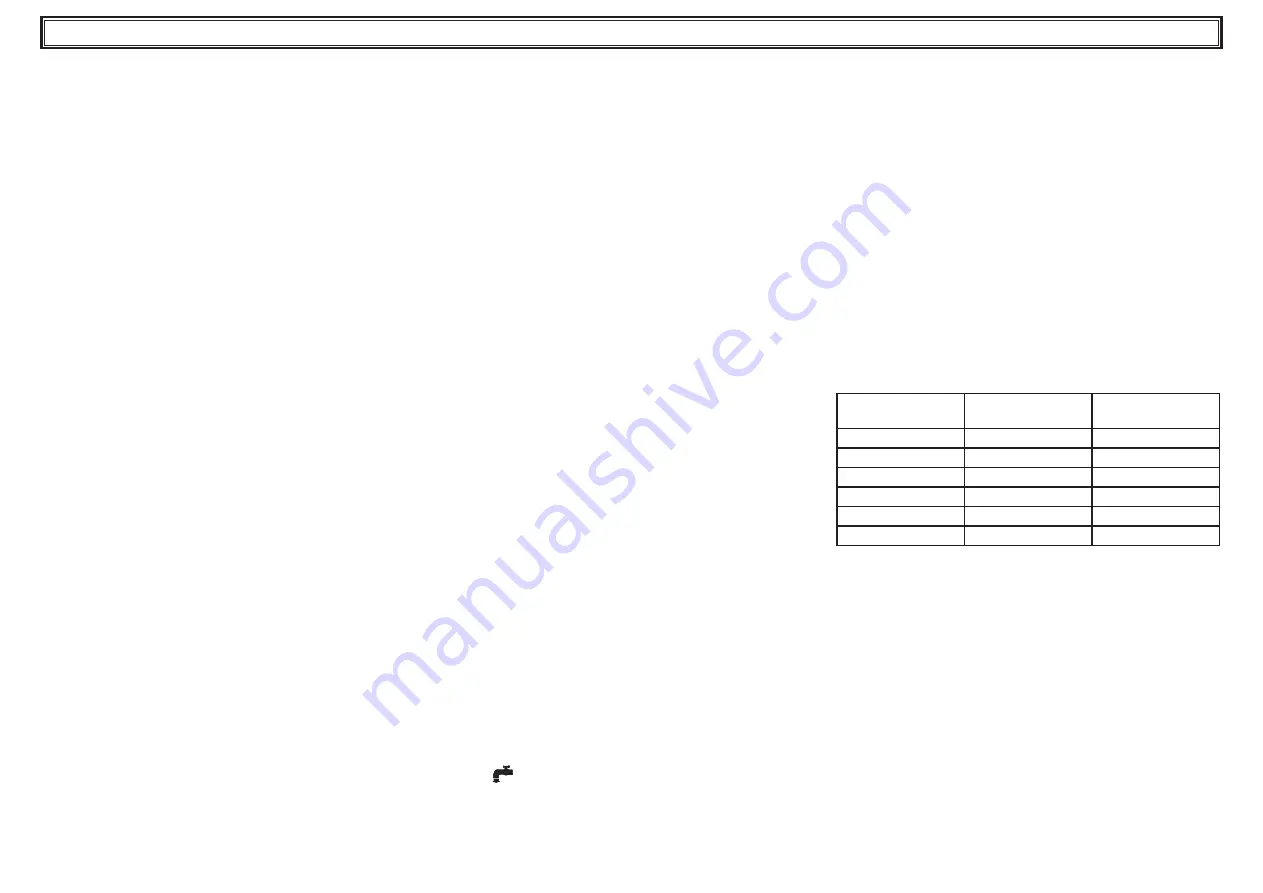

Outlet water

temperature [°C]

Ethylene glycol

(% vol.)

Ambient

temperature

4

5

-2

2

10

-5

0

15

-7

-2

20

-10

-4

25

-12

-6

30

-15

3.3.3 Expansion

tank

To avoid the possibility of an increase or decrease in the volume of the

fl uid due to a signifi cant change in its temperature causing damage to

the machine or the water circuit, we recommend installing an expansion

tank of suitable capacity.

The expansion tank must be installed on intake to the pump on the rear

connection of the tank.

The minimum volume of an expansion tank to be installed on a closed

circuit can be calculated using the following formula:

V=2 x Vtot x (Pt min - P t max)

where

Vtot= vol. circuit total (in litres)

P t min/max= specifi c weight at the minimum/maximum temperature

reached by the water [kg/dm3].