6

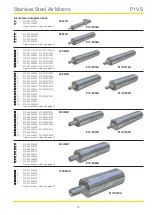

Stainless Steel Air Motors

P1V-S

Principles of motor operation

There are a number of designs of air motors. Parker Hannifin

has chosen to use the vane rotor design, because of its simple

design and reliable operation. The small external dimensions

of vane motors make them suitable for all applications. The

complete unit consists of a motor built together with a plan-

etary reduction gear to give the required speed and torque at

the output shaft.

The design of a vane air motor consists of a rotor which

incorporates a given number of vanes all enclosed within a

cylinder. The cylinder will include three ports; an inlet pressure

port, an exhaust port and a residual port. Reliable starting is

ensured by the fact that the inlet air presses the vanes against

the cylinder wall prior to rotation. During operation, the vanes

are pressed outwards by centrifugal force. The air pressure

always acts at right angles to the vane surface, which means

that the available torque is determined by the surface area

of the vanes and by the air pressure. As each vane reached

it’s lowest point air is released through the exhaust port. As

the rotation continues air may be trapped and compressed

between vanes. This compressed air is released through the

residual port. The residual port doubles as the pressure port

when the motor is operated in the reverse direction.

Inlet

Inlet, left

Residual outlet

Inlet, right

1 Rotor cylinder

Rotor

3 Vanes

4 End piece with bearing

The performance characteristics of each motor are shown in

a family of curves as above, from which torque, power and air

consumption can be read off as a function of speed. Power

is zero when the motor is stationary and also when running at

free speed (100%) with no load. Maximum power (100%) is

normally developed when the motor is braked to approximately

half the free speed (50%).

Torque at free speed is zero, but increases as soon as a load

is applied, rising linearly until the motor stalls. As the motor can

stop with the vanes in various positions, it is not possible to

specify an exact starting torque. However, a minimum starting

torque is shown in all tables.

Air consumption is greatest at free speed, and decreases

with decreasing speed, as shown in the above diagram.

Torque, power and air consumption graphs

1

2

3

Outlet

Outlet

4

3

1

2

4

Outlet

40

20

60

80

100

160

120

140

200

180

100

100

20

40

60

80

20

40

60

80

M

Q

P

Q [%], P [%]

M [%]

n [%]

Possible working range of motor.

Optimum working range of motor.

Higher speeds = more vane wear

Lower speeds with high torque = more gearbox

wear

The curve is for 6 bar

P = power

Q = air consumption

M = torque

n = speed

Please refer to the curve on page 65

for these pressures:

3, 4, 5, 6 and 7 bar

Summary of Contents for 1P1V-S020A00005

Page 66: ...66 Stainless Steel Air Motors P1V S...

Page 67: ......