404XE Series Product Manual

13

Parker Hannifin Corporation

EMN Automation

-

Parker

Irwin, Pennsylvania

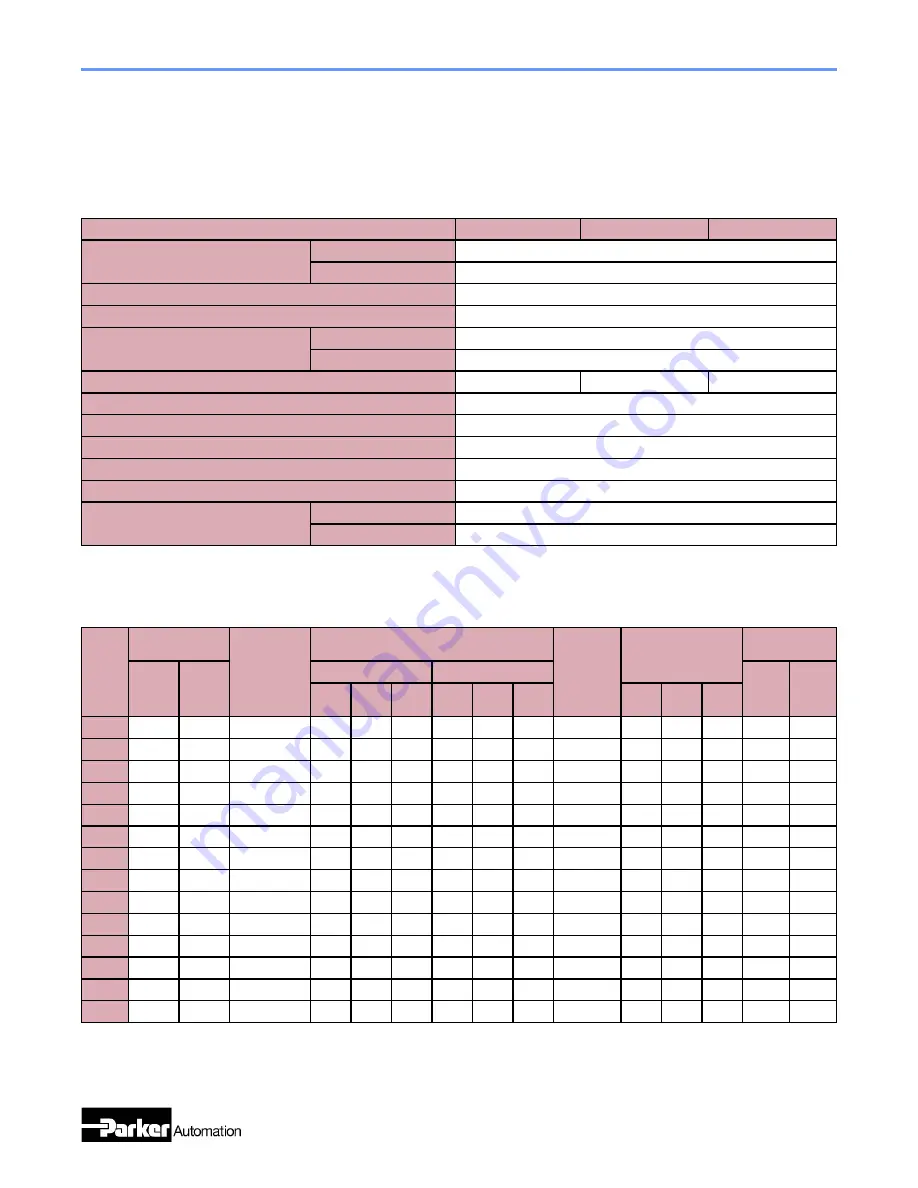

404XE Common Performance Characteristics

5mm Lead (D2 Option)

10mm Lead (D3 Option)

20mm Lead (D4 Option)

Bidirectional Repeatability

-

µm

T01 to T11 Option

+/

-

10

T12 to T15 Option

+/

-

15

Duty Cycle

100%

Max Acceleration

(1)

-

m/s

2

(in/s

2

)

20 (787)

Normal Load Capacity

(2)

-

kgf (lbs)

Short Carriage (NL Option)

61.3 (135)

Long Carriage (VL Option)

122.6 (270)

Axial Load Capacity

(1)(2)

-

kgf (lbs)

60 (132)

70 (154)

70 (154)

Drive Screw Efficiency

90%

Max Breakaway Torque

-

Nm (oz

-

in)

0.25 (35)

Max Running Torque (Rated @ 2rps)

-

Nm (oz

-

in)

0.21 (30)

Linear Bearing Coefficient of Friction

0.01

Ballscrew Diameter

-

mm (in)

16.0 (0.63)

Carriage Weight

-

kgf (lbs)

Short Carriage (NL Option)

0.215 (0.47)

Long Carriage (VL Option)

0.495 (1.09)

(1)

Applies to units with long carriage (VL Option).

(2)

Refer to life/load charts.

Performance Specifications

-

404XE

404XE Travel Dependent Performance Characteristics

Travel

Option

Travel

Positional

(3)(4)

Accuracy

-

µm

Input Inertia

-

10

-

5

kg

-

m

2

Max Screw

Speed

-

rps

Max Velocity

-

m/s

Total Table

Weight

-

kgf

NL

Option

VL

Option

NL Option

VL Option

NL

Option

VL

Option

5mm

Lead

10mm

Lead

20mm

Lead

5mm

Lead

10mm

Lead

20mm

Lead

5mm

Lead

10mm

Lead

20mm

Lead

T01

25 mm

N/A

42

0.81

N/A

N/A

N/A

N/A

N/A

72

0.36

0.73

1.50

1.42

1.70

T02

50 mm

N/A

50

0.94

0.98

N/A

N/A

N/A

N/A

72

0.36

0.73

1.50

1.61

1.89

T03

100 mm

33 mm

58

1.19

1.23

1.12

1.21

1.30

1.40

72

0.36

0.73

1.50

1.95

2.23

T04

150 mm

83 mm

66

1.44

1.48

1.32

1.46

1.55

1.60

72

0.36

0.73

1.50

2.35

2.63

T05

200 mm

133 mm

74

1.69

1.73

1.51

1.71

1.80

1.79

72

0.36

0.73

1.50

2.59

2.87

T06

250 mm

183 mm

82

1.94

1.99

1.70

1.96

2.06

1.99

72

0.36

0.73

1.50

2.97

3.25

T07

300 mm

233 mm

90

2.20

2.24

1.90

2.21

2.31

2.18

72

0.36

0.73

1.50

3.34

3.62

T08

350 mm

283 mm

98

2.45

2.49

2.09

2.47

2.56

2.37

72

0.36

0.73

1.50

3.50

3.78

T09

400 mm

333 mm

106

2.70

2.74

2.29

2.72

2.81

2.57

72

0.36

0.73

1.50

3.83

4.11

T10

450 mm

383 mm

114

2.95

2.99

2.48

2.97

3.07

2.76

72

0.36

0.73

1.50

4.09

4.37

T11

500 mm

433 mm

122

3.21

3.25

2.67

3.22

3.32

2.96

72

0.36

0.73

1.50

4.22

4.50

T12

550 mm

483 mm

130

3.46

3.50

2.87

3.48

3.57

3.15

72

0.36

0.73

1.50

4.55

4.83

T13

600 mm

533 mm

138

3.71

3.75

3.06

3.73

3.82

3.34

69

0.34

0.68

1.32

4.87

5.15

T15

700 mm

633 mm

154

4.21

4.25

3.45

4.23

4.33

3.73

52

0.26

0.52

1.00

5.12

5.40

(3)

Positional accuracy applies to inline motor configurations only. Contact factory for parallel motor specifications. Positional specifications are based on un-

loaded conditions and apply to individual axes only.

(4)

Consult factory for specifications with linear feedback.