Parker Hannifin Corporation

EMN Automation

-

Parker

Irwin, Pennsylvania

47

406LXR Series Product Manual

Chapter 6

-

Maintenance and Lubrication

6. Remount carriage end caps. Insure that the compression springs are present under the shoulder screws in

the carriage end caps. Due to springs screws will need to be pressed into holes to start thread engagement.

Square Rail Bearing Lubrication

See previous section on

Internal Access

for access

to interior of positioner.

Tools Requires:

Shell Alvania RL 2

Isopropyl Alcohol

Clean paper towels

Small brush

Lubrication Type:

Use Shell Alvania RL 2 pn# 003

-

3686

-

30, non

-

EP, lithium soap thickened greases. This grease

also inhibited with additives that promote long

service life and provide excellent lubrication and

corrosion protection. Shell Alvania Grease RL 2

is readily pumpable in pressure grease

dispensing systems.

Lubricant Appearance:

Smooth

-

textured, amber colored.

Maintenance Frequency:

Square rail bearing blocks are lubricated at our

facility prior to shipment. For lubrication

inspection and supply intervals following

shipment, apply grease every 1000 hours of

usage. The time period may change depending

on frequency of use and environment. Inspect

for contamination, chips, etc, and replenish

according to inspection results.

Lubricant Application:

Wipe the rails down the entire length with a

clean cloth. Apply lubrication on the rails

allowing a film of fresh grease to pass under the

wipers and into the recirculating bearings.

After bearings are relubricated, clean encoder

tape scale located on inside wall of table. Use

only isopropyl alcohol and a clean lint free cloth

or paper towel. Using a lint free cloth, wipe

down linear tape scale to remove and dirt or

grease.

Caution!

DO NOT use and other solvent to

clean the encoder scale. Use of other

solvents will permanently damage the

encoder scale. Use only isopropyl alcohol.

Note: Do not use/mix petroleum base grease with

synthetic base grease at any time. For lubrication

under special conditions consult factory.

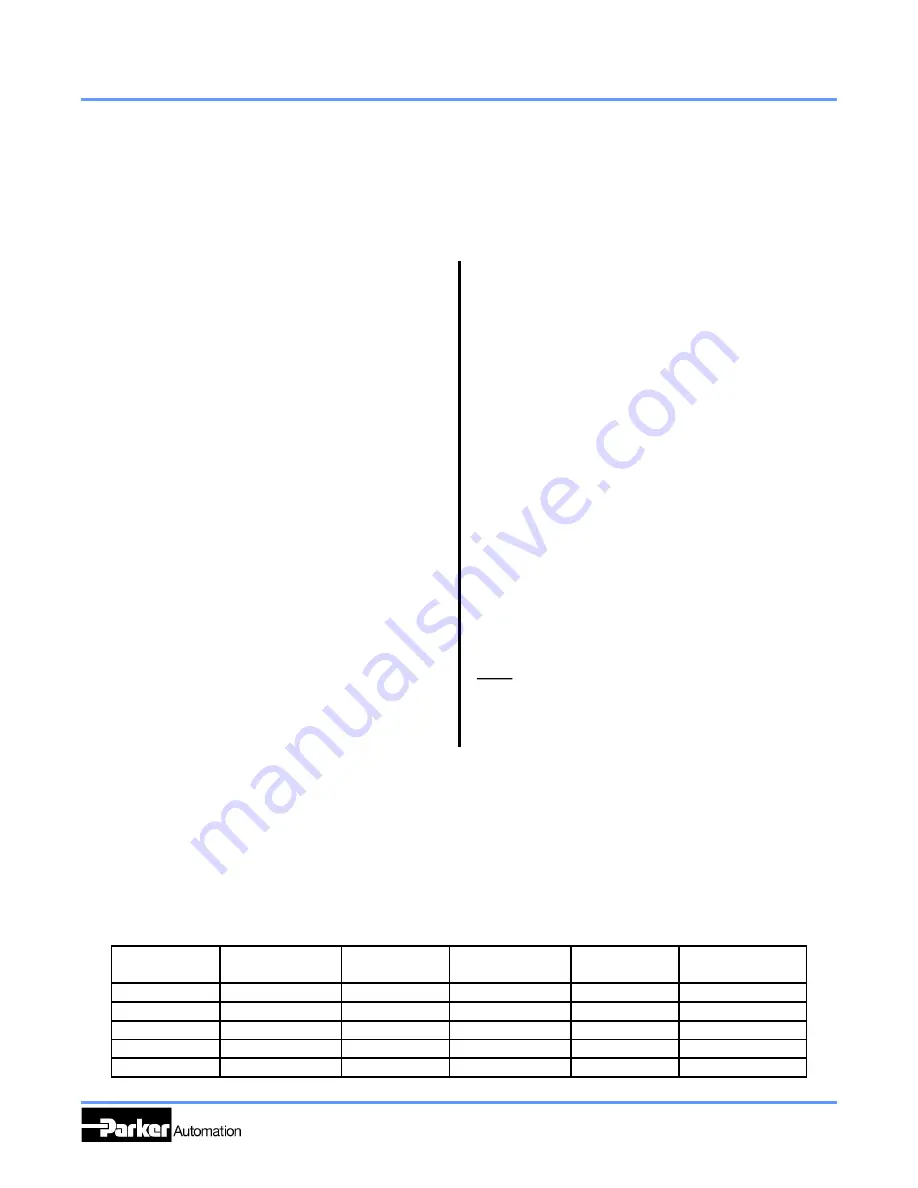

Cable Management Module Replacement

Tools Requires:

Replacement Cable Management Module

Hex keys: 2.5mm and 2mm

Ball nose hex key: 3mm

Travel Code

Replacement

Part Number

Travel Code

Replacement

Part Number

Travel Code

Replacement

Part Number

T01

006

-

2415

-

01

T06

006

-

2415

-

06

T11

006

-

2415

-

11

T02

006

-

2415

-

02

T07

006

-

2415

-

07

T12

006

-

2415

-

12

T03

006

-

2415

-

03

T08

006

-

2415

-

08

T13

006

-

2415

-

13

T04

006

-

2415

-

04

T09

006

-

2415

-

09

T14

006

-

2415

-

14

T05

006

-

2415

-

05

T10

006

-

2415

-

10

Replacement Cable Module Part Numbers

Summary of Contents for 406LXR Series

Page 30: ...26 ...

Page 38: ...34 ...

Page 64: ...Parker Hannifin Corporation EMN Automation Parker Irwin Pennsylvania Notes ...

Page 65: ...Parker Hannifin Corporation EMN Automation Parker Irwin Pennsylvania Notes ...

Page 66: ...Parker Hannifin Corporation EMN Automation Parker Irwin Pennsylvania Notes ...

Page 67: ...Parker Hannifin Corporation EMN Automation Parker Irwin Pennsylvania Notes ...

Page 68: ......