Axial Piston Pump

Series PV, series 47 and higher

Bulletin MSG30-3245-INST/UK

Installation manual

7

Parker Hannifin Manufacturing Germany GmbH & Co. KG

Pump & Motor Division Europe

Chemnitz, Germany

The adjustment of the compensating pressure is

performed for the standard pressure com pen sa-

tor directly at the compensator.

To adjust the pressure, the lock nut (SW 13) is to

be loosened and the adjustment spindle is to be

turned (screw driver).

Turning clockwise will increase the compensat-

ing pressure, turning counter-clockwise will

decrease the compensating pressure.

The compensating pressure can be adjusted in a

range from 15 to 350 bar (approx. 125 bar/turn).

By turning the pressure pilot cartridge housing

the compensator differential can be adjusted.

It is factory set to 15±1 bar and should not be

changed (approx. 20 bar/turn).

Different compensator differential settings can

cause instability or excessive power losses.

By using adapter kit PVCMCK** (below 47de-

sign) / PVCCK** (since 47 design) the standard

Size

Displacement change per mm (appr

ox. cm³/U)

Displacement change per turn (appr

ox. cm³/U)

Minimum adjustable

displacement

(appr

ox. cm³/U)

PV016

1.5

1.5

9

PV020

1.5

1.5

13

PV023

1.5

1.5

16

PV028

1.5

1.5

20

PV032

2.2

2.2

17

PV040

2.2

2.2

25

PV046

2.2

2.2

30

PV063

3.4

5.1

35

PV080

3.4

5.1

50

PV092

3.4

5.1

65

PV140

5.6

8.4

20

PV180

5.6

8.4

60

PV270

6.8

10.2

120

PV360

8.6

12.9

180

pressure compensator can be made remote

controllable. This adapter replaces one of the side

plugs. Adapters are available for G1/4, M14x1.5

ISO 6149-1 and 7/16-20 UNF.

See also the remarks in chapter 6.

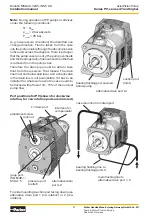

3. Standard pressure compensator, code ...MMC

compensator differential adjustment

pressure adjustment

lock nut

lock nut

Adjustment should only be made with the pump

working at full displacement (not compensated)

and at a low output. At full displacement the piston

area of the servo piston is under case pressure.

Opening the self-sealing nut will only cause a

negligible leakage under these conditions.

Turning the adjustment screw clockwise will re-

duce the pumps displacement. The table shows

the displacement change per mm resp. per turn

and the minimum adjustable displacement.

Note:

All pumps are adjusted and tested after

assembly in our factory. Only the compensator

pressure needs to be adjusted. That is done on

the pilot valve spindle. No other adjustments on

the compensator or the pump is required. Only

after service or repair a basic adjustment needs

to be performed.