21

The 6911 Keypad

F3 : DATA LOGGING

Use this page to configure regular-interval, data-logging of the main display screen text.

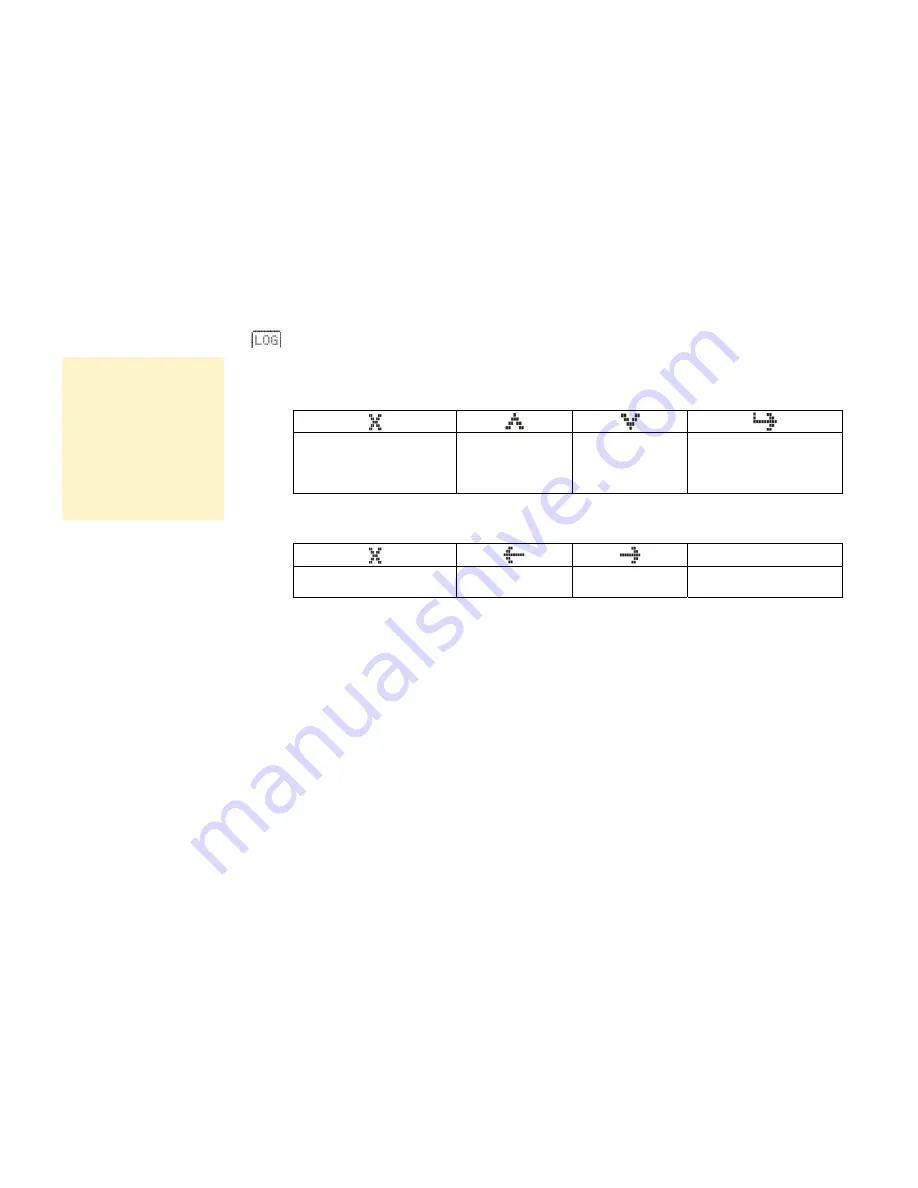

When the FILE page is selected, the soft keys are redefined, as shown below, for navigating and

selecting whilst using the page.

Exit page, or exit sub-menu

declining changes

Row up

(as Rotary Control

clockwise action)

Row down

(as Rotary Control

anticlockwise

action)

Display sub-menu, or

accept changes

During item selection or during setting selection mode, the soft keys are again redefined and function

as follows:

OK

Exit character edit without

changing anything

Move the cursor

left

Move the cursor

right

Exit character edit and

accept changes

With the Multi-Keys displaying SET4, press the "LOG" soft key to enter the Data-Logging page.

How To Configure Data Logging

The menu is displayed in order of completion:

1.

Name the file for use in data logging and insert the memory card that will store the file.

2.

Select the trigger that will start the data logging, or select continuous data logging.

3.

Set the time interval between the data logs.

4.

Select the units for each time interval.

5.

Enable data logging by setting continuous logging, or by entering the total number of samples to be

made.

Disclaimer

Although every effort has

been taken to ensure the

accuracy of the data

logging function, Parker

SSD Drives cannot accept

responsibility for damage,

injury, or expenses

resulting from the use of

data logging.

This manual was downloaded on www.sdsdrives.com

+44 (0)117 938 1800 - info@sdsdrives.com