© 2008 Parker Hannifi n Corporation

ISO 9001 CERTIFIED

312068 ECN: 9078 06/11/09

Safe Operation (See Bulletin RSBCV)

People doing any work on a refrigeration system must be

qualifi ed and completely familiar with the system and the

Refrigerating Specialties Division valves involved, or all other

precautions will be meaningless. Th

is includes reading and

understanding pertinent Refrigerating Specialties Division

Product Bulletins and Safety Bulletin RSB prior to installation

or servicing work.

Where cold refrigerant liquid lines are used, it is necessary

that certain precautions be taken to avoid damage which

could result from liquid expansion. Temperature increase in a

piping section full of solid liquid will cause high pressure due

to the expanding liquid which can possibly rupture a gasket,

pipe or valve. All hand valves isolating such sections should

be marked, warning against accidental closing, and must

not be closed until the liquid is removed. Check valves must

never be installed upstream of solenoid valves, or regulators

with electric shut-off , nor should hand valves upstream of

solenoid valves or downstream of check valves be closed until

the liquid has been removed.

It is advisable to properly install relief devices in any section

where liquid expansion could take place. Avoid all piping

or control arrangements which might produce thermal or

pressure shock.

For the protection of people and products, all refrigerant

must be removed from the section to be worked on before a

valve, strainer, or other device is opened or removed. Flanges

with ODS connections are not suitable for ammonia service.

Warranty

All Refrigerating Specialties products are under warranty

against defects in workmanship and materials for a period of

one year from date of shipment from factory. This warranty

is in force only when products are properly installed, fi eld

assembled, maintained, and operated in use and service as

specifi cally stated in Refrigerating Specialties Catalogs or

Bulletins for normal refrigeration applications, unless other-

wise approved in writing by the Refrigerating Specialties

Division. Defective products, or parts thereof returned to the

factory with transportation charges prepaid and found to be

defective by factory inspection, will be replaced or repaired at

Refrigerating Specialties option, free of charge, F.O.B. factory.

Warranty does not cover products which have been altered,

or repaired in the fi eld, damaged in transit, or have suffered

accidents, misuse, or abuse. Products disabled by dirt or other

foreign substances will not be considered defective.

Th

e express warranty set forth above constitutes the only

warranty applicable to Refrigerating Specialties products, and

is in lieu of all other warranties, expressed or implied, written

including any warranty of merchantability, or fi tness for a

particular purpose.

In no event is Refrigerating Specialties

responsible for any consequential damages of any nature what-

soever. No employee, agent, dealer or other person is authorized

to give any warranties on behalf of Refrigerating Specialties, nor

to assume, for Refrigerating Specialties, any other liability in

connection with any of its products.

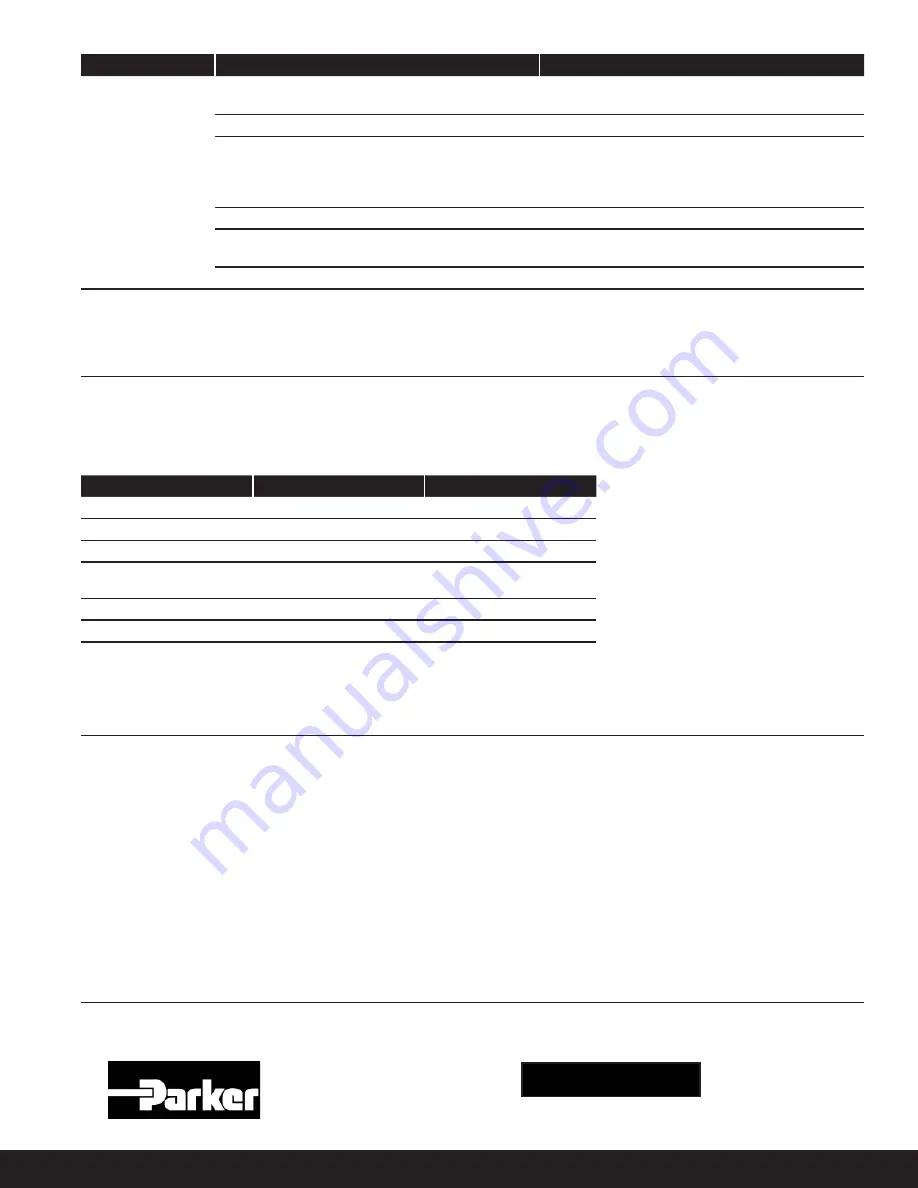

Symptom

Probable Cause

Correction

Failure to open,

close, or regulate

Piston jammed due to excessive dirt

Flush clearance space between piston and

cartridge bore with refrigeration oil solvent

Valve Manually Open

Close manual bypass stem by tuning clockwise

Adjusting stem improperly positioned:

a. Turned in too far. Does not open (inlet regulator)

b. Not turned far enough. Does not close (inlet

regulator). Does not open (outlet regulator)

Position adjusting stem properly

Passage “N” clogged

Clean passage “N”

Pilot seat dirty or eroded

Clean and smooth pilot seat. If diaphragm is

removed, replace with new gasket and O-Ring

Regulator installed backwards

Re-install regulator in proper position

System Control

cannot be

maintained -

unstable valve

operation

Improper regulator selection:

a. Actual load is mush lower than regulator capacity

b. Actual pressure drop across valve higher than

originally intended

c. Combination of a and b

Replace cartridge with one of suitable size

A4W Service Pointers

Location

Description (SAE)

Torque mkg (Ft-Lbs)

Bonnet Screws

M6 x 18 MM

(7)

Port Plate Screws

M10 x 45 MM

(35)

Bonnet Seal Cap

—

Snug

Solenoid Pseudo

Assembly

—

Snug

Gauge Port Plug

1/4” NPT

1.4 (10)

Pilot Plug

7/16-20

Snug

A4W Torque Requirement Table