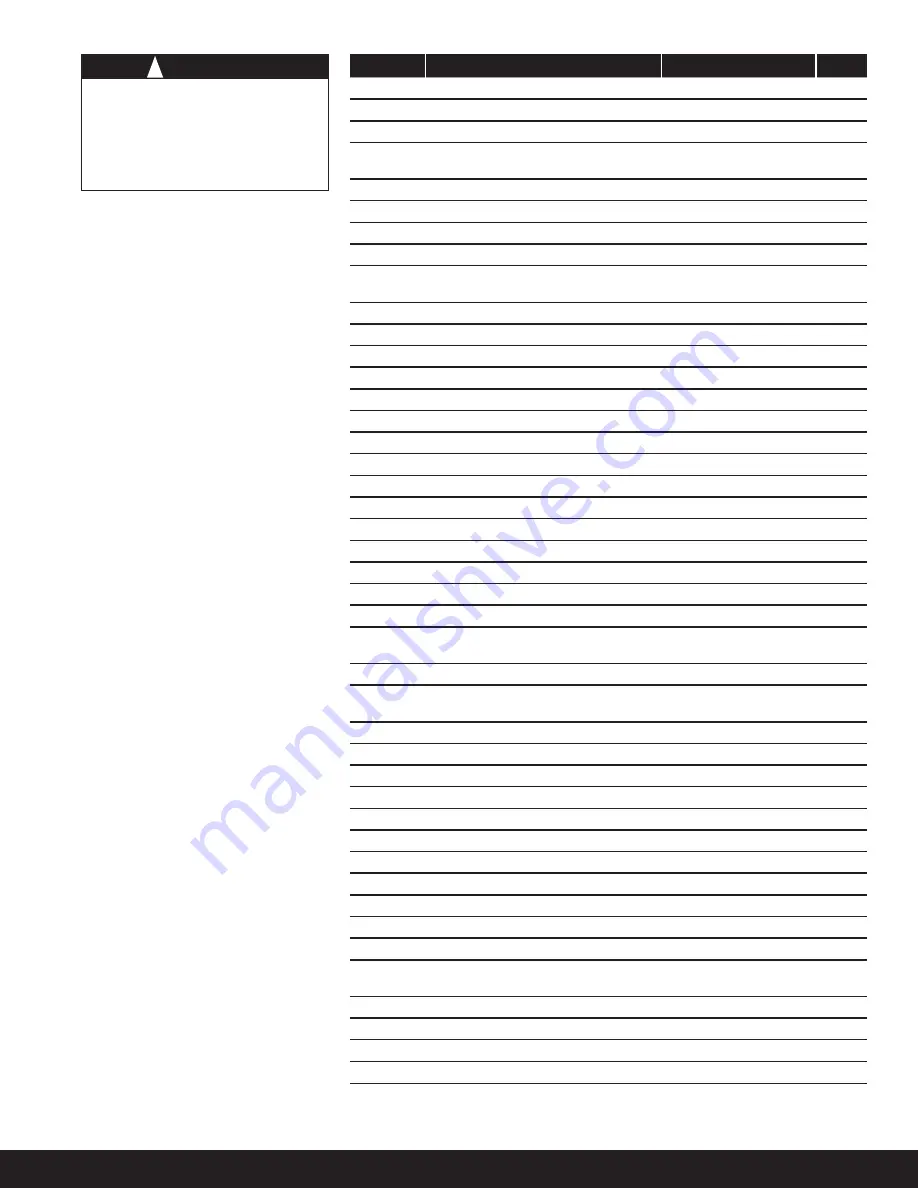

Bulletin 22-00 A / Page 7

Item No.

Description

Material

Qty

1

Seal Cap

6061 Al

1

2

O-Ring, 0.551 ID x 0.691 OD x 0.07

Neoprene

1

3

Bonnet

304L S.S.

4

4

M6 x 18MM Bolt

DIN-ISO

Standard 3506-1

1

5

O-Ring, 0.25 ID x 0.35 OD x 0.062

Neoprene

1

6

Washer, 0.39 ID x 0.625 OD x 0.031

Acetal

1

7

Stem

303 S.S.

1

8

Top Plate, Spring with Roll Pin

1215 Steel

1

9

Spring, Bonnet

Music Wire ASTM

A-228

1

10

Bottom Plate, Spring

1215 Steel

1

11

Ball, 0.281 DIA

440C S.S.

1

12

Follower, Diaphragm

1215 Steel

1

13

O-Ring, 1.5 ID x 1.625 OD x 0.062

Neoprene

1

14

Gasket, 1.875 ID x 2.3 OD x 0.015

Klingersil C-4401

1

15

Diaphragm

301/302 S.S.

1

16

O-Ring, 2.0 ID x 2.125 OD x 0.062

Neoprene

1

17

O-Ring, 0.25 ID x 0.375 OD x 0.062

Neoprene

1

18

Plug, Pilot

303 S.S.

1

19

Seat, Pilot

1215 Steel

1

20

O-Ring, 0.437 ID x 0.563 OD x 0.062

Neoprene

1

21

Spring, Pilot

S.S. ASTM A-313

1

22

Seal Cap

6061-T6 Al

1

23

O-Ring, 0.813 ID x 0.938 OD x 0.062

Neoprene

1

24

Seat, Pilot Plug (“S” Only)

303 S.S.

1

25

Bolt, M10 x 45MM

DIN-ISO

Standard 3506-1

4

26

Plug, Gauge 1/4” NPT

PTFE Coated Steel

1

27

Plug, Pipe 1/16” NPT

Black Oxide

Finish Steel

1

28

O-Ring, 0.125 ID x 0.25 OD x 0.062

Neoprene

1

29

Stem, Manual Opening

303 S.S.

1

30

Nut, Retainer

416 S.S.

1

31

Plug Cap, Manual Opening 7/16-20

6061-T6 Al

1

32

Pin, Roll

420 S.S.

1

33

Seat, Solenoid

303 S.S.

1

34

Port Plate

6061-T6 Al

1

35

Gasket, Port Plate 0.031

MP 15

1

36

Ring, Retaining 2.174 Internal

302 S.S.

1

37

Ring, Backing

302/304 S.S.

1

38

Ring, Seal 2.528 ID x 2.706 OD

PTFE S.S.

1

39

Spring, Piston

Music Wire

ASTM A-228

1

40

Piston

303 S.S.

1

41

Ring, Seal

Tefl on (PTFE)

1

42

Ring, Wear

PTFE EMS-103

1

43

Body

304L S.S.

1

A4W, A4WB, A4WS, A4WBS Parts List

Caution

Regulators with ‘B’ features can only

be adjusted with the pilot solenoid

de-energized. Regulators with the

‘S’ feature can only be adjusted with

the solenoid energized.

!

A4W Disassembly

(See also Bulletin RSBCV)

All A4W series regulators can be

disassembled and all serviceable

and moving parts replaced without

disturbing the piping, but of course,

dis assembly will cause exposure of

some section of piping to atmosphere,

which should be addressed before

disassembly by evacuation and re-

claim of the refrigerant.

For the A4W series inlet regulators, the

seal cap (#1) should be loosened and

the adjustment stem (#7) backed out

until no further spring compression

is felt. If it is known that access to the

range spring (#9) and diaphragm (#14)

is not required, the sub-assembly from

the port plate up can remain intact

and the regulator set point can thus

be preserved, avoiding the need for

gross adjustments when the valve is

put back in service. If access to the

pilot assembly (#17 – 21) on an A4W

is required, then the compression

must be taken off the range spring as

described above, and the bonnet bolts

(#4) removed. If a solenoid fea ture is

incorporated, the solenoid coil (#45)

should now be removed by removing

the coil clip (#44). Never energize a

solenoid coil that is not mounted and

secured on its solenoid actuator (#46).

After removing the bonnet assembly

bolts, the bonnet can be easily

lifted off , and will usually leave the

diaphragm resting on top of the gasket

(#15) and o-ring (#16). Th

e bolts (#25)

retaining the lower sub-assembly can

now be removed. Th

e wear aspects of

the port plate (#34) are the diaphragm

and the pilot assembly, which is

pressed into the top of the port plate.

Remove the diaphragm and inspect

carefully for cracks, or scarring around

the pilot seat area. Th

is is most easily

done by looking down a piece of

large tubing, through the diaphragm,

at a safety lamp or similar light