Page 2 / Bulletin 22-05 A

Port Size

Connection Size

(SW, BW)

Body Size

Kv

Cv

20 mm (3/4”)

3/4”, 1”

1”

10.8

12.6

25 mm (1”)

3/4”, 1”, 1-1/4”

1”, 1-1/4”

12.5

14.6

32 mm (1-1/4”)

1-1/4”, 1-1/2”

1-1/4”, 2”

22.3

26

40 mm (1-1/2”)

1-1/2”, 2”

2”

30

35

50 mm (2”)

1-1/2”, 2”

2”

41.1

48

A4W Port, Connection, and Flow Coeffi cient Table

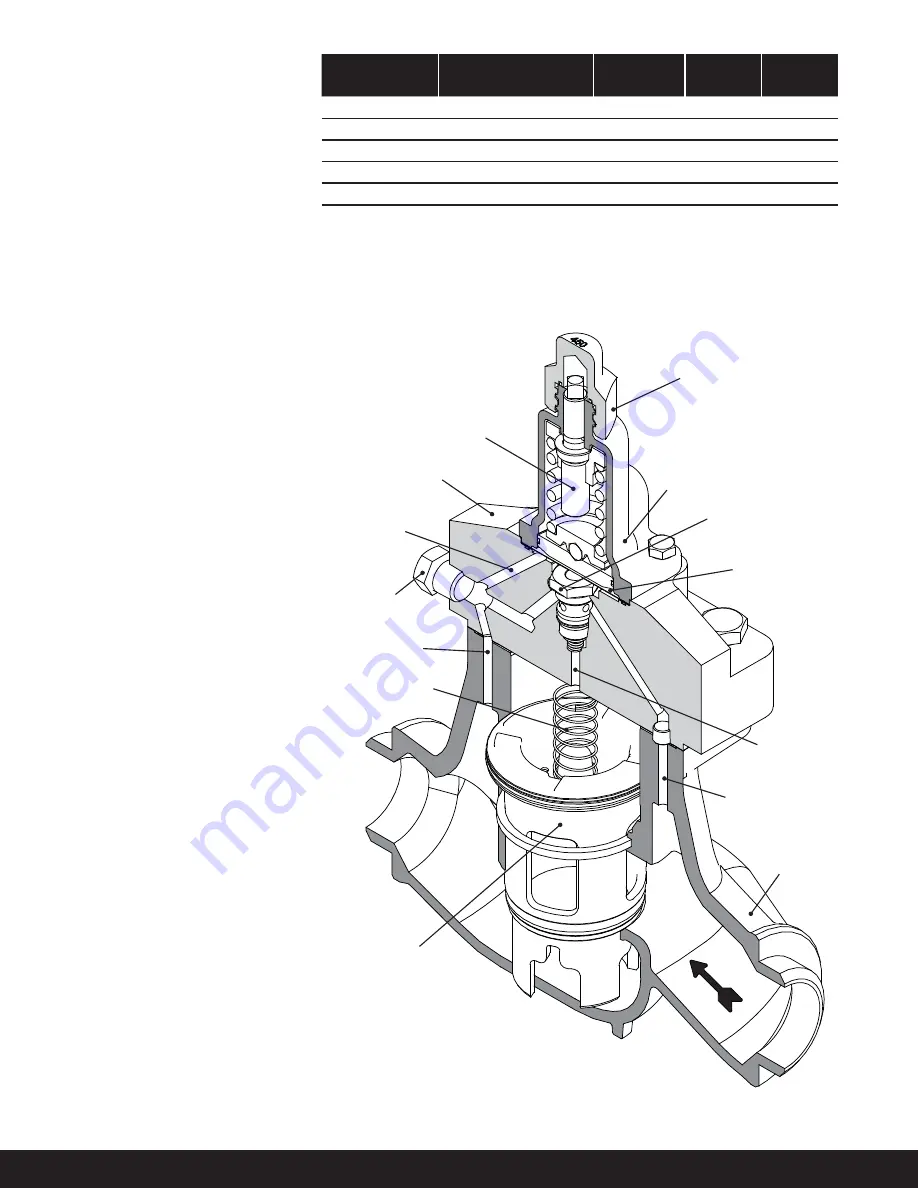

A4WO Outlet Pressure Regulator Cross Section

(1-1/2” Valve Body Shown)

Seal

Cap

Bonnet

Assembly

Diaphragm

Outlet

Pressure

Passage (N)

Closing

Spring

Modulating

Plug (Piston)

Stainless

Steel Body

Gauge

Port

Aluminum

Port Plate

Adjustment

Stem

Passage (T)

Passage (P)

Inlet Pressure

Passage (N)

Pilot Plug

Description

All A4WO outlet pressure regulators

are pilot operated and require a

minimum of 0.14 bar (2 psig) pressure

drop across the valve to fully open.

Th

e valves are an integrated assembly

of three modules:

A body, which contains the

1.

modulating plug, but is ordered to

suit a particular connection size.

Th

e port size defi nes the size of

the body;

A port plate, which defi nes the

2.

valve function. Control features

can be added by incorporating

pilot solenoids: either an Electric

Shut-Off (S) or a Electric Wide

Open Bypass (B);

Th

e bonnet, which contains the

3.

range set spring and adjustment

stem.

Th

e A4WO is a normally closed valve

furnished with socket weld and weld

neck options only. Th

is unique design

allows the regulator to be welded

into the line without disassembly, yet

provides full access for cleaning and

servicing from the top only.

Th

ese valves will modulate to maintain

a pressure as set for in the fi eld, in

spite of fl uctuations in load, changes

in ambient, changes in available

refrigerant fl ow paths, and other

operating variances. Appropriately

sized, these valves will modulate the

fl ow of liquid or vapor, high side or

low side in a wide variety of system

arrangements. Each port size will

have a specifi c maximum capacity

at full opening corresponding to the

available or sensible-pressure.

Th

e throttle range on this new design

is greatly enhanced, resulting in

optimal performance at low load

conditions. Current regulator designs

can regulate down to 20% of a valves

maximum rating. Th

e A4W series or

regulators can regulate down to 10% of

the valves maximum capacity.

Th

ese valves are generally ordered

with close upstream strainer to

prevent entrance of foreign material

into the valve and the rest of the