02-9242ME

: AHL Series Pump

Operation & Maintenance Manual | 04/22

7

Section 6.0

Installation

Please read this manual in its entirety before

attempting to operate an Parker Autoclave

Engineers high pressure liquid pump

!

WARNING

AHL Pumps have a maximum sound level

of 90 dBA. Wear hearing protection while working

with or near the pump.

!

CAUTION

Installation to be performed only by properly

trained individuals.

!

WARNING

Proper protective safety gear must be worn while

installing and operating the pump.

!

WARNING

Always bolt the pump to a substantially

solid surface using the slotted holes provided.

!

WARNING

Section 6.1

Compressed Air Supply

Unless otherwise noted, all air line accessories for

the pump air drive should have, at minimum, a 1/2

"

FNPT connection. The tubing/piping used to

connect the components should have the maximum

ID the pressure rating will allow. Reducing the size

before the air inlet will reduce air pressure flow and

reduce flow rate of the pump.

NOTICE

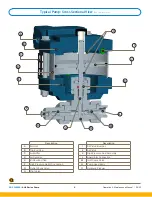

The main air drive connection port on the pump is a

female 1

"

FNPT and is located in the spool base housing.

An additional female 1/8

"

FNPT air pilot valve connection

port is located in the middle plate at the opposite side of

the 1

"

NPT air inlet.

This pilot connection must be plumbed to an unregulated

and filtered air source. The purpose of this connection

is to aid in low pressure differential start-up and restart

of the pump while providing a more accurate pressure

control. The pump will not function if this unregulated air

supply is not connected to the pilot valve supply port.

The use of an air line lubricator is not required

and is not recommended.

The oil in the air

lubricator will cause the factory installed grease to

be purged from the pump. Once an air lubricator is

used the pump can never again be operated without

an air lubricator.

NOTICE

An air line filter with a minimum 5 microns filtration rating

must be used on the supply line. If the air supply is not

dry, a mist separator must be used to remove moisture in

the air line.

The pump is designed to function from 20 psi to 110 psi

(1.4 to 7.6 bar) air input pressure, however maximum

inlet air pressure is limited by the maximum liquid output

pressure.