HY10-1632-M2.1/US

Parker Hannifin Corporation

Accumulator & Cooler Division

United States

Installation & Disassembly

Bladder Accumulators

4

Tools & Equipment

Tools & Equipment

Tools and Equipment

Description

Part Number

Use

Charging & Gauging Assembly

Refer to Maintenance & Installation

Guide HY10-1632-M2

Various styles available based on pre-charge,

accumulator size & style.

Pull Rod (1 Qt - 2 ½ Gallon)

085109 0250

Pull rods are available in single or multiple lengths for

different size accumulators. The pull rods attach to the

gas valve of the bladder for ease of assembly into shell

during assembly.

Pull Rod (5 Gallon)

085109 0500

Pull Rod (10-11 Gallon)

085109 1000

Pull Rod (15 Gallon)

085109 1500

Core Repair Tool

582441 0000

Core Installation Tool

300987

Spanner Wrench

085110 0000

Fits all standard size bladder accumulators. Used to

remove hydraulic port assembly from the accumulator.

Box Or Adjustable Wrenches

Blunt Flathead Screwdriver or Ball Head

Hex Wrench

See pictures above

Rounded edges. Used to tuck in hydraulic port O-ring.

Torque Wrench

Used to establish proper torque

Soft Head Hammer

May be required to loosen locking ring in conjection with

spanner wrench

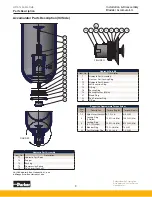

Figure 1:

Pull rods, Spanner wrench, Core repair tool,

and Core installation tool

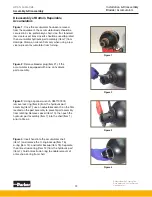

Figure 2:

Typical rounded edge flathead screwdriver or ball

head hex

Clean & Inspect

Cleaning:

All metal parts should be cleaned with

a cleaning agent. Seals and soft parts should be

wiped clean.

Bladder (Item 2):

Inflate bladder to normal size.

Wash bladder with a soap solution. If soap solution

bubbles, discard bladder. After testing, deflate

bladder immediately.

Hydraulic Port Assembly (Item 7):

Inspect assembly

for damage. Check the poppet valve (Item 7.2) and

spring (Item 7.4) to see that the poppet spins freely

and the spring functions properly. In cases where the

accumulator is used with water, check assembly for rust

and/or defective plating. If rust is detected, clean with

commercial rust remover. If parts are pitted, replace

with new components. If protective plating is damaged,

replace with new components.

Seals:

Check anti-extrusion ring (Item 12) and soft seals

for damage and wear. Replace all worn and damaged

seals with Parker’s original equipment seals.

Shell (Item1):

After shell has been cleaned with a

cleansing agent, check the inside and outside of shell.

Special attention should be given to the area where the

bladder stem (Item 2) and hydraulic port assembly (Item

7) pass through the shell. Any nicks or damages in this

area could destroy the accumulator bladder or damage

new seals. If this area is pitted, consult the factory.