10

Parker Hannifin Corporation

Bulletin TI-HFX-3D

Maintenance

To avoid system damage and/or personal harm, isolate the Balston Nitrogen Generator from

To avoid system damage and/or personal harm, isolate the Balston Nitrogen Generator from

To avoid system damage and/or personal harm, isolate the Balston Nitrogen Generator from

To avoid system damage and/or personal harm, isolate the Balston Nitrogen Generator from

To avoid system damage and/or personal harm, isolate the Balston Nitrogen Generator from

the compressed air supply and fully depressurize prior to performing any maintenance

the compressed air supply and fully depressurize prior to performing any maintenance

the compressed air supply and fully depressurize prior to performing any maintenance

the compressed air supply and fully depressurize prior to performing any maintenance

the compressed air supply and fully depressurize prior to performing any maintenance

activities.

activities.

activities.

activities.

activities.

All maintenance activities for the Balston HFX-3 and HFX0-3 Nitrogen Generators should be

All maintenance activities for the Balston HFX-3 and HFX0-3 Nitrogen Generators should be

All maintenance activities for the Balston HFX-3 and HFX0-3 Nitrogen Generators should be

All maintenance activities for the Balston HFX-3 and HFX0-3 Nitrogen Generators should be

All maintenance activities for the Balston HFX-3 and HFX0-3 Nitrogen Generators should be

performed by suitable personnel using reasonable care.

performed by suitable personnel using reasonable care.

performed by suitable personnel using reasonable care.

performed by suitable personnel using reasonable care.

performed by suitable personnel using reasonable care.

Required maintenance for the Balston Nitrogen Generation System consists of changing the prefilter

and final filter cartridges (annually), changing the galvanic cell in the oxygen analyzer (annually),

checking the performance of the system, and calibrating the oxygen analyzer. The recommended

service schedule and replacement part numbers are outlined at the end of this section. The calibra-

tion procedure for the oxygen analyzer is outlined on page 6. The analyzer should be calibrated on

a regular basis, as dictated by the application.

Changing filter cartridges more frequently will translate into direct energy savings and reduced

operating costs. Annual electricity costs to operate a typical 100 HP compressor can be as high as

$50,000. Pressure drop in the system adds to this expense. A system operating at 100 psig that is

exeriencing a 2 psig pressure drop through a filter, requires an additional 1% in operating energy

costs or approximately $500.00+ per year.

Replacement prefilter cartridges, final membrane filter cartridges, and galvanic cells may be ordered

through your local representative. For convenience, these replacement items have been packaged

into a maintenance kit for each generator. Maintenance Kits provide a 6 month supply of filtration

replacement components.

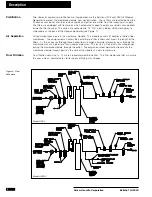

The only tools required to change the prefilter cartridges and the final membrane filter cartridge is a

Phillips head screwdriver. All filter housings which require routine service are easily accessible

when the front filtration access panel is opened. (Remove the four corner screws.) The two coalesc-

ing prefilters are Balston 2002N-1B1-DX and 2002N-1B1-BX filter assemblies (see Figure 7). Re-

place these filter cartridges with Balston 100-12-DX and 100-12-BX filter cartridges. When replacing

the prefilter cartridges, be sure to install the proper grade filter in the proper housing (the housings

are labeled). The final membrane filter is a Balston 2002N-0A0-95 filter assembly. Replace this

membrane filter cartridge with a Balston Grade GS 100-12-95 membrane filter cartridge.

The filter cartridges in the filter assemblies are removed by: twisting the filter bowl clockwise 1/8 of a

turn while pushing up gently, lowering the filter bowl away from the filter head, and unscrewing the

element retainer from the base of the cartridge. Insert the new filter cartridge and reassemble the

housing in reverse order.

The time required to service all three stages of filtration is less than 15 minutes.

Filter Cartridge

Replacement

!